Why Understanding Hydraulic Parts is Essential for Your Machinery Efficiency

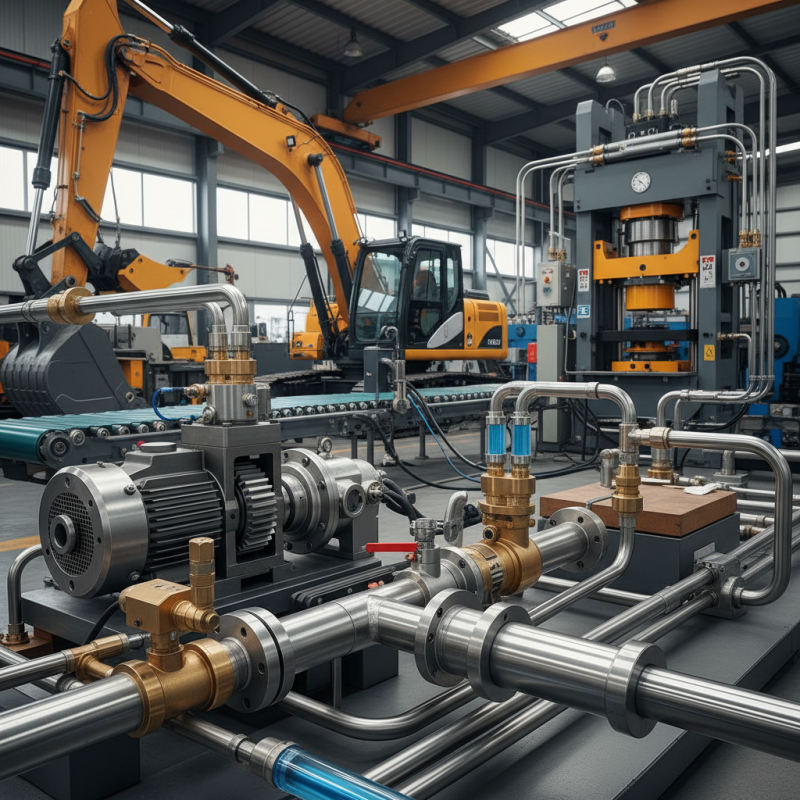

Understanding hydraulic parts is crucial for anyone involved in the maintenance and operation of machinery. These components play a pivotal role in the efficiency and effectiveness of hydraulic systems used across various industries, from construction to manufacturing. Hydraulic parts, such as pumps, valves, and cylinders, work in unison to convert fluid power into mechanical energy. A comprehensive understanding of these components not only enhances the performance of your machinery but also extends its lifespan.

In the intricate world of machinery, every hydraulic part must function optimally to ensure seamless operation. Issues like leaks, pressure drops, or component failure can significantly hinder productivity and lead to costly downtime. By gaining insights into the mechanics and functionalities of hydraulic parts, operators and technicians can diagnose problems early, perform necessary maintenance, and make informed decisions regarding repairs or upgrades. Ultimately, this knowledge fosters a proactive approach to machinery management, promoting efficiency and reliability in operations.

The Importance of Hydraulic Parts in Machinery Functionality

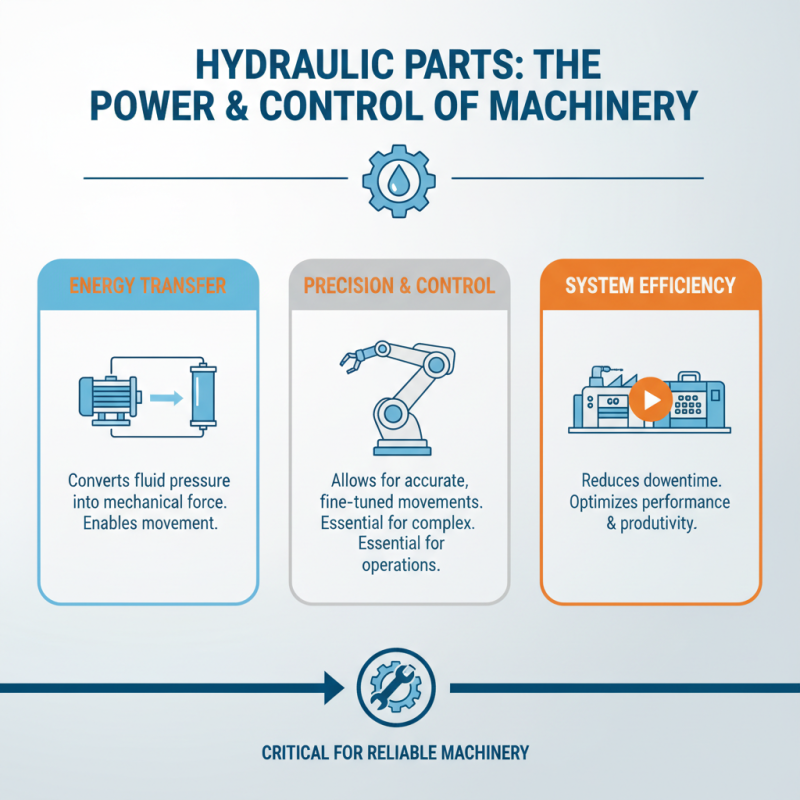

Hydraulic parts play a critical role in the functionality of machinery, providing the necessary power and control to operate various systems efficiently. These components are integral in transferring energy through fluid pressure, allowing for precise movements and actions in equipment. Without properly functioning hydraulic parts, machinery can suffer from performance issues, which can lead to increased downtime and operational inefficiencies.

One essential tip for maintaining hydraulic parts is to regularly check fluid levels and quality. Hydraulic fluid acts as both a lubricant and a power carrier, and contaminated or low-quality fluid can lead to premature wear and system failures. Additionally, ensuring that filters are replaced and hydraulic lines are inspected can prevent leaks and maintain optimal pressure levels, ultimately improving the efficiency of the machinery.

Another important consideration is to monitor the temperature of hydraulic systems. Overheating can significantly impair performance and decrease the lifespan of hydraulic components. Implementing cooling systems or ensuring proper ventilation can help regulate temperatures and safeguard against potential damage. By prioritizing these maintenance practices, you can enhance the functionality and longevity of your machinery, ensuring it operates at peak efficiency.

Key Components of Hydraulic Systems and Their Roles

Hydraulic systems are integral to various machinery, utilizing fluid power to perform tasks efficiently. Understanding the key components of these systems is crucial for maintaining optimal performance and reliability. One of the primary components is the hydraulic pump, which converts mechanical energy into hydraulic energy by moving fluid from the reservoir into the system. The efficiency of a hydraulic pump directly affects the entire system, as it dictates the amount of fluid pressure and flow available for operation.

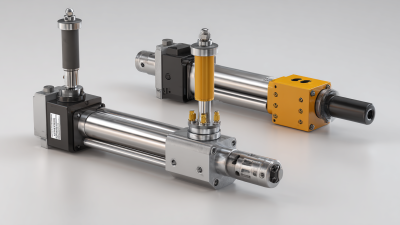

Another essential component is the hydraulic cylinder, which transforms hydraulic energy back into mechanical energy. These cylinders are responsible for driving the movements of machinery through the extension and retraction of a piston. The design and materials used in hydraulic cylinders can significantly impact their durability and responsiveness. Additionally, hydraulic hoses and fittings play a critical role in connecting these components, ensuring that fluid is transported safely and efficiently throughout the system. Regular inspection and maintenance of these parts are vital to prevent leaks and failures, which can lead to downtime and costly repairs in machinery operations.

How Hydraulic Efficiency Impacts Overall Machine Performance

Hydraulic efficiency plays a pivotal role in the overall performance of machinery. A well-functioning hydraulic system ensures smooth operation, precise control, and not only enhances the productivity of machines but also extends their lifespan. According to industry reports, hydraulic inefficiencies can lead to energy losses of up to 30%, culminating in increased operational costs and reduced machinery effectiveness. Thus, understanding the intricacies of hydraulic parts and their roles is instrumental for anyone involved in machinery operation and maintenance.

Regular maintenance and optimization of hydraulic components can have significant positive impacts on machine performance. For instance, ensuring that hydraulic fluid is clean and at the proper viscosity can improve system efficiency by as much as 20%. Additionally, maintaining seals and couplings can prevent leaks that contribute to inefficiency.

Tips:

- Regularly inspect and replace hydraulic filters to maintain optimal fluid cleanliness.

- Monitor hydraulic fluid temperature; overheating can lead to increased wear and reduced efficiency.

- Invest in training for operators to recognize early signs of hydraulic system inefficiencies, allowing for proactive maintenance rather than reactive fixes.

Hydraulic Efficiency and Its Impact on Machine Performance

Common Issues with Hydraulic Parts and Their Solutions

Hydraulic systems are critical components in various machinery, but they can encounter several common issues that affect performance.

One prevalent problem is leakage, which can stem from worn seals, loose fittings, or damaged hoses.

Leakage not only leads to a loss of hydraulic fluid but also results in reduced pressure, hampering the machine's efficiency.

Regular inspection and maintenance can help identify these issues early, allowing for timely replacement of seals and tightening of fittings.

Another common issue is contamination of the hydraulic fluid, often caused by dirt or debris entering the system.

This contamination can lead to increased wear on components and eventual failure of hydraulic parts.

Implementing effective filtration systems and regular fluid changes can significantly mitigate this risk.

Additionally, keeping the machinery clean and inspecting it regularly can prevent external contaminants from entering the hydraulic circuit,

thereby prolonging the lifespan of the parts and ensuring optimal performance.

Finally, overheating is a frequent challenge faced by hydraulic systems, often caused by excessive workloads or inefficient cooling systems.

Overheating can deteriorate fluid quality and damage components, resulting in costly repairs.

Ensuring that your machinery operates within the recommended load limits and that cooling systems are functioning correctly

can help maintain appropriate temperatures and enhance overall efficiency.

Best Practices for Maintaining Hydraulic Components for Longevity

Maintaining the longevity of hydraulic components is vital for optimizing machinery efficiency and reducing downtime. According to a report by the National Fluid Power Association, about 70% of hydraulic system failures can be attributed to contamination and improper maintenance. To counter this issue, adopting best practices for hydraulic maintenance is crucial. Regularly scheduled inspections and fluid analysis can help identify contaminants and ensure the fluid's viscosity remains within the recommended range, preventing unnecessary wear on components.

Another important aspect of hydraulic maintenance is the timely replacement of filters and seals. The International Society for Fluid Power estimates that regularly changing filters can improve system efficiency by up to 25%, while also prolonging the life of hydraulic fluid. Implementing a structured maintenance program that includes monitoring system pressures and temperatures can provide invaluable insights into your machinery's health, allowing for preventative measures to be taken before significant issues arise. By prioritizing these practices, operators can ensure the reliability and efficiency of their hydraulic systems, leading to enhanced overall productivity.

Why Understanding Hydraulic Parts is Essential for Your Machinery Efficiency - Best Practices for Maintaining Hydraulic Components for Longevity

| Component | Function | Maintenance Tips | Expected Lifespan (Years) |

|---|---|---|---|

| Hydraulic Pump | Converts mechanical energy to hydraulic energy | Regularly check for leaks and ensure proper oil level | 8-15 |

| Hydraulic Cylinder | Converts hydraulic energy into mechanical motion | Inspect seals for wear and ensure adequate lubrication | 10-20 |

| Hydraulic Hose | Transfers hydraulic fluid between components | Look for signs of abrasions and check for kinks or cracks | 5-10 |

| Hydraulic Filter | Removes impurities from hydraulic fluid | Replace every 500 hours of operation or as recommended | 3-5 |

| Hydraulic Fluid | Transmits power and lubricates components | Regularly check fluid level and replace fluid as needed | 2-5 |

Related Posts

-

Exploring Hydraulic Continental Solutions at the 138th Canton Fair 2025 Trends and Market Data

-

Top 10 Hydraulic Controls You Need to Know for Optimal Performance

-

Addressing Common Hydraulic Flow Control Challenges: Insights and Data from Industry Experts

-

7 Essential Tips for Choosing Hydraulic Flow Control Valves for Your Business

-

Essential Guide to Understanding Hydraulics Products for Everyday Applications

-

Revolutionizing Flow Control: How Automated Valves are Shaping the Future of Industrial Automation

skip to Main Content

skip to Main Content