2026 Top Proportional Valves for Precision Control in Automation

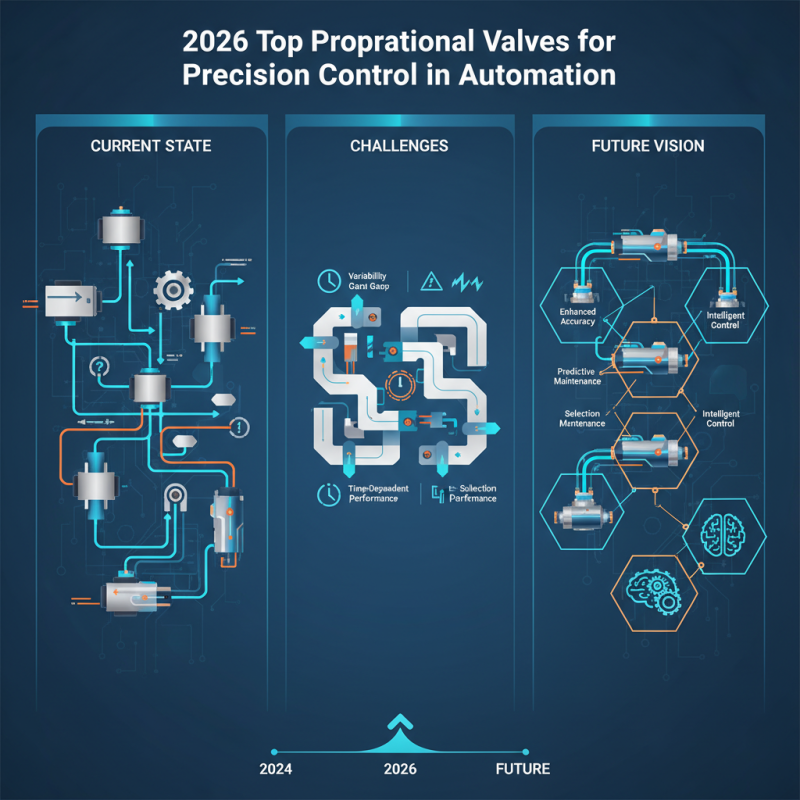

In the world of automation, precision control is vital. Proportional valves play a critical role in achieving this precision. These components allow for smooth adjustments to fluid flow and pressure. In various applications, they significantly enhance efficiency and responsiveness.

However, selecting the right proportional valves can be challenging. The market is filled with options that claim to offer superior performance. Understanding the specific needs of your automation system is essential. Not all valves are created equal; some may fail to meet your requirements over time.

Moreover, the future of automation demands enhanced reliability and accuracy. Proportional valves must evolve to meet these standards. They should address not just current demands, but also anticipate future challenges. This is a complex journey, but one that can lead to remarkable improvements in automation technology.

2026 Overview of Proportional Valves in Automation Industry

Proportional valves play a crucial role in automation, allowing for precise control of fluid flow and pressure. In 2026, the industry is experiencing significant advancements in the design and functionality of these valves. Reports indicate that the global proportional valve market is projected to reach $4.5 billion, driven by increasing demand for automation in various sectors.

Data shows that applications in the manufacturing and automotive industries account for over 55% of this growth. This highlights the need for improved efficiency and accuracy in industrial processes. However, challenges remain. Many companies struggle with integrating new technology into existing systems. This gap can lead to operational delays and increased costs. As technology evolves, so must our strategies for implementation.

Tip: Invest in training programs for staff to effectively understand new proportional valve technology. This can reduce friction during transitions. Regular maintenance checks are essential too. They ensure optimal performance and prolong valve life.

While the potential for proportional valves is immense, their adoption isn't without flaws. Companies may overlook the importance of quality control in procurement. This can result in subpar performance and heightened failure rates. Addressing these issues early is vital for sustained success in automation.

Key Features of Top Proportional Valves for Precision Control

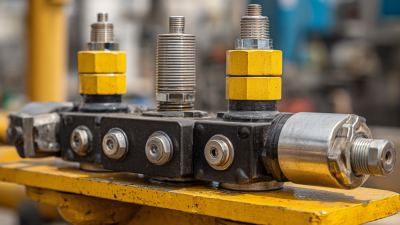

Proportional valves play a crucial role in automation. They ensure precise control of fluid flow and pressure. This precision is essential for applications requiring exact movements, like robotic arms. The best proportional valves offer a variety of features for optimal performance.

One key feature to look for is modulation capability. A valve should adjust flow rates accurately. This capability allows for smooth transitions in operation. Another aspect is the response time. Fast response times enhance control and minimize delays. A valve may excel in flow modulation but lack in response.

Lastly, compatibility with various control systems matters. Some valves may connect seamlessly, while others cause issues. This sometimes leads to inefficiencies. Understanding these details is vital. These potential pitfalls remind us about the importance of thorough testing. Choosing the right valve requires evaluating both features and performance in real-world settings.

Leading Brands and Models of Proportional Valves in 2026

Proportional valves play a vital role in automation systems. They ensure precise control of fluid flow and pressure. In 2026, several leading models stand out for their reliability and efficiency. These valves will offer various features, enhancing integration into automated systems. Users appreciate valves with compact designs and intuitive controls.

Some models struggle with temperature regulation. Heat fluctuations can impact performance. It's essential to consider how these changes affect operation. Moreover, while many brands advertise exceptional functions, real-world applications reveal limitations. Some valves fail under heavy loads, resulting in unexpected downtime. Users must weigh the benefits against potential drawbacks.

Automatic adjustments are another focus in 2026. Enhanced technology allows for responsive changes in fluid dynamics. Yet, not every system integrates seamlessly. Users may face challenges in calibration. The experience varies from one environment to another. Understanding these nuances is crucial for making informed choices in valve selection.

2026 Top Proportional Valves for Precision Control in Automation

| Model | Flow Rate (L/min) | Pressure Rating (bar) | Control Type | Response Time (ms) | Operating Temperature (°C) |

|---|---|---|---|---|---|

| Model A | 30 | 210 | Electric | 10 | -20 to 80 |

| Model B | 50 | 240 | Hydraulic | 15 | -10 to 70 |

| Model C | 25 | 150 | Pneumatic | 8 | -30 to 60 |

| Model D | 40 | 200 | Electric | 12 | -20 to 75 |

| Model E | 60 | 250 | Hydraulic | 20 | 0 to 90 |

Applications of Proportional Valves in Industrial Automation

Proportional valves play a crucial role in industrial automation, ensuring precise control of fluid flow and pressure. These valves allow for the fine-tuning of machinery operations, which is vital in various applications such as robotics and assembly lines. According to industry reports, the global proportional valves market is projected to grow at a CAGR of 6.5% through 2026. This growth highlights the increasing reliance on automation technology across sectors.

Nonetheless, the implementation of proportional valves isn't without challenges. Proper calibration is essential; otherwise, performance may suffer. Inaccurate settings can lead to inefficiencies, resulting in wasted resources. Furthermore, maintenance is often overlooked. Many facilities underestimate the wear and tear on these components. As a result, downtime can impact productivity.

Despite these hurdles, the benefits are substantial. Proportional valves enable better energy efficiency in hydraulic systems, reducing operational costs. For instance, using proportional control can cut energy consumption by up to 20%. This efficiency makes a compelling case for investing in high-quality valves. The potential for enhanced precision and responsiveness in industrial processes remains a driving force behind their adoption.

Future Trends and Innovations in Proportional Valve Technology

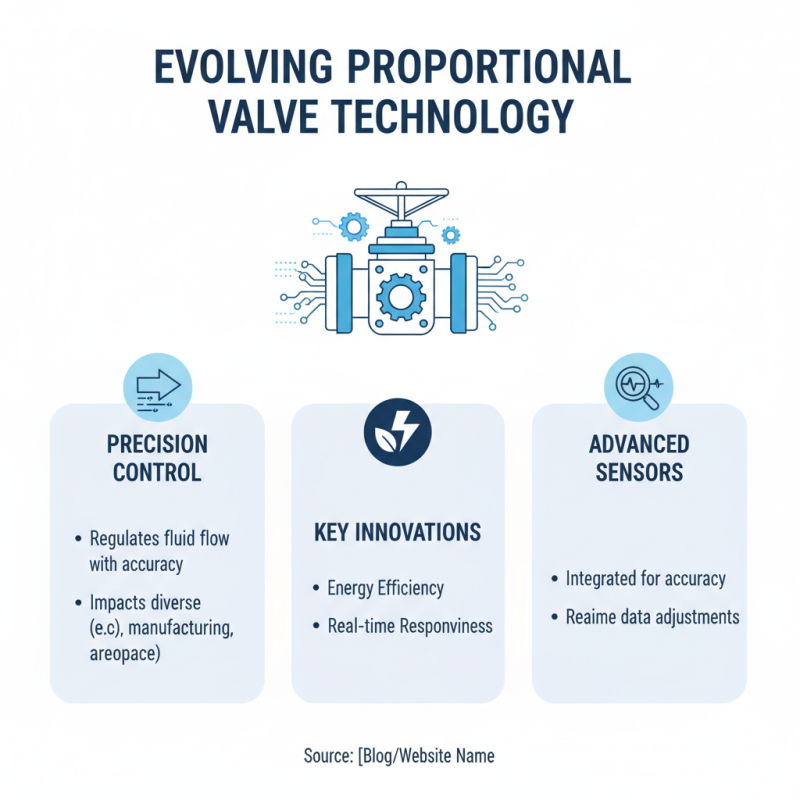

As automation technology evolves, proportional valves are becoming more sophisticated. These valves control fluid flow with precision, impacting various industries. Innovations are focusing on energy efficiency and real-time responsiveness. Advanced sensor technology is now being integrated into valve systems. This allows for more accurate adjustments based on real-time data.

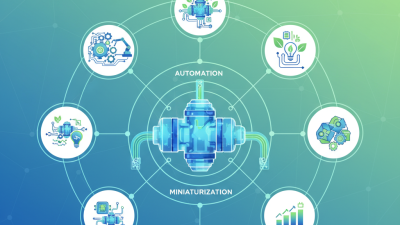

The future of proportional valve technology includes the rise of smart valves. These valves connect seamlessly with IoT devices. This connectivity enhances data collection and analysis, leading to actionable insights. However, the integration poses challenges. Many companies struggle with data overload and inconsistent performance metrics.

Sustainability is another key trend. Manufacturers aim to create environmentally friendly materials and processes. This shift is inspiring numerous startups to explore new designs. Yet, not all designs are effective or feasible. There’s a significant learning curve in balancing innovation and practicality.

Related Posts

-

Essential Checklist for Selecting the Right Proportional Valves for Your Applications

-

12 Key Reasons Why Directional Control Valves Are Essential for Efficient Fluid Power Systems

-

Understanding the Importance of Directional Control Valves in Fluid Power Systems

-

Top 2025 Trends in Directional Control Valves You Need to Know

-

Unlocking Global Opportunities for Check Valves at China Import and Export Fair 2025

-

How to Choose the Right Hydraulic Pressure Relief Valve for Your Application

skip to Main Content

skip to Main Content