Top 10 Hydraulic Solenoid Valves You Need to Know About for Optimal Performance

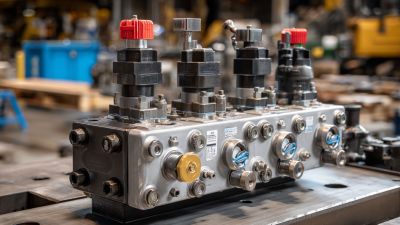

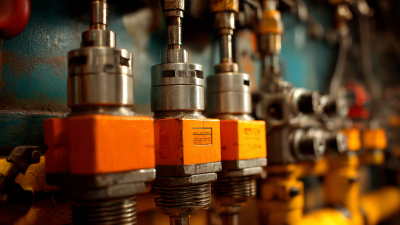

In the world of fluid dynamics and automation, hydraulic solenoid valves play a pivotal role in enhancing system efficiency and performance. As vital components in hydraulic systems, these valves control the flow and direction of liquids with precision, making them indispensable in various industrial applications. Understanding the different types and functionalities of hydraulic solenoid valves is crucial for engineers and technicians who seek to optimize their systems.

This article aims to explore the top 10 hydraulic solenoid valves that are essential for achieving optimal performance. Each of these valves brings unique characteristics, allowing for effective control over fluid power systems. By delving into their operational principles, benefits, and applications, readers will be equipped with the knowledge necessary to select the best hydraulic solenoid valves for their specific needs. Ultimately, recognizing the strengths of these components can lead to improved efficiency, reliability, and productivity in any hydraulic setup.

Overview of Hydraulic Solenoid Valves and Their Importance

Hydraulic solenoid valves play a crucial role in hydraulic systems, regulating fluid flow and pressure to ensure optimal performance across a variety of applications, from manufacturing to automotive industries. According to a recent market report by Research and Markets, the global hydraulic valves market was valued at approximately $18 billion in 2022 and is anticipated to grow at a compound annual growth rate (CAGR) of about 4.5% through 2030. This growth is largely driven by the increasing automation in industrial processes and the demand for efficient hydraulic systems.

These valves are essential for controlling the operation of hydraulic actuators, translating electrical signals into precise mechanical movements. Their efficiency directly impacts the reliability and performance of hydraulic machinery. The importance of maintaining high-quality hydraulic solenoid valves cannot be overstated, as they significantly influence response times, energy consumption, and overall system integrity. A study conducted by the Hydraulic Institute found that approximately 70% of hydraulic system failures can be traced back to valve malfunctions, underscoring the necessity for regular maintenance and selection of high-performance components in hydraulic applications.

Key Features to Consider When Selecting Hydraulic Solenoid Valves

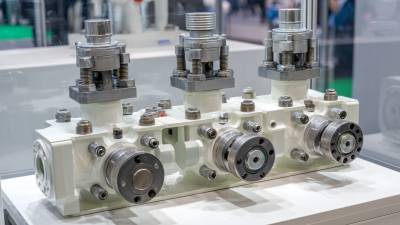

When selecting hydraulic solenoid valves, there are several key features you should consider to ensure optimal performance in your hydraulic systems. First and foremost, the valve's response time is crucial. A quick response time enhances the overall efficiency and effectiveness of hydraulic operations, reducing lag and improving system reliability. Additionally, it's important to assess the valve's flow rate. A higher flow rate can improve performance in high-demand applications, allowing for greater fluid movement and control.

Another feature to evaluate is the valve's duty cycle. Understanding the duty cycle helps in choosing a valve that can withstand the specific operational demands of your system, ensuring longevity and minimizing the risk of failure. Similarly, consider the operating pressure range of the valve. Selecting a valve designed for the required pressure levels of your system is vital to maintain safe and efficient operations. Lastly, the materials used in construction are crucial for durability. Valves made from corrosion-resistant materials are ideal for environments exposed to harsh conditions, as they significantly enhance the lifespan and reliability of the components.

Top 10 Hydraulic Solenoid Valves for Enhanced Performance

When it comes to optimizing hydraulic systems, selecting the right solenoid valve is crucial for enhanced performance. These components play a pivotal role in controlling the flow and pressure within hydraulic circuits, ultimately affecting the efficiency and responsiveness of the entire system. Choosing a high-quality hydraulic solenoid valve can lead to significant improvements in operation, reducing downtime and maintenance costs while ensuring reliable performance under varying conditions.

One of the key factors to consider is the valve's construction and materials, as they directly influence durability and resistance to environmental factors such as temperature and pressure fluctuations. Additionally, the size and type of solenoid used in the valve can affect its response time and power consumption. To achieve optimal performance, it's essential to match the hydraulic solenoid valve characteristics with the specific requirements of your application, whether it's for heavy machinery, automation systems, or other industrial uses. Understanding these nuances will ensure that the selected valves deliver the efficiency and performance needed for seamless operations.

Top 10 Hydraulic Solenoid Valves You Need to Know About for Optimal Performance

| Model | Operation Type | Voltage (V) | Flow Rate (L/min) | Maximum Pressure (bar) | Material |

|---|---|---|---|---|---|

| SV-01 | Normally Closed | 24 | 40 | 210 | Aluminum |

| SV-02 | Normally Open | 12 | 30 | 180 | Stainless Steel |

| SV-03 | Bi-Directional | 48 | 60 | 220 | Brass |

| SV-04 | Single Acting | 24 | 50 | 200 | Plastic |

| SV-05 | Double Acting | 230 | 70 | 250 | Aluminum |

| SV-06 | Normally Closed | 12 | 55 | 190 | Brass |

| SV-07 | Normally Open | 48 | 65 | 230 | Aluminum |

| SV-08 | Bi-Directional | 24 | 80 | 210 | Stainless Steel |

| SV-09 | Single Acting | 230 | 75 | 200 | Plastic |

| SV-10 | Double Acting | 48 | 85 | 250 | Brass |

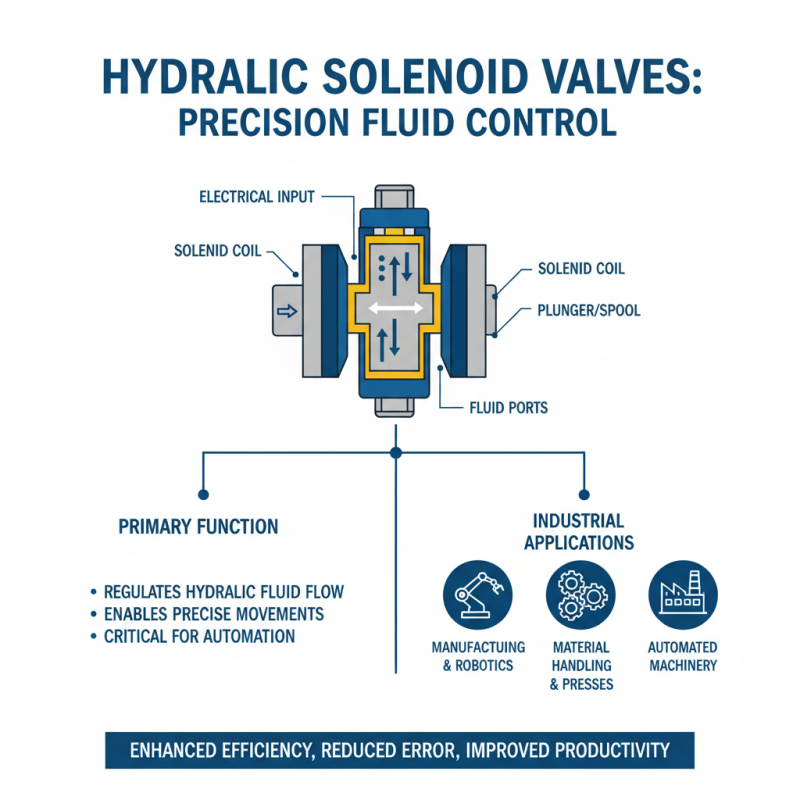

Application Areas for Hydraulic Solenoid Valves in Various Industries

Hydraulic solenoid valves play a critical role in various industries, serving as essential components for fluid control in hydraulic systems. Their primary function is to regulate the flow of hydraulic fluid, enabling precise movements and operations in a myriad of applications. In manufacturing, these valves are pivotal in automated machinery, where they control actuators that drive material handling equipment, presses, and robotics. This automation enhances efficiency, reduces human error, and improves overall productivity, making hydraulic solenoid valves indispensable in modern production environments.

In the automotive sector, hydraulic solenoid valves are crucial for braking systems, ensuring safety and responsiveness in vehicle performance. They also find applications in construction equipment, where they manage the hydraulic functions in excavators, loaders, and cranes. By facilitating smooth control of power and motion, these valves contribute to effective operation in heavy-duty tasks. Additionally, industries such as agriculture utilize hydraulic solenoid valves in irrigation systems and farm machinery, allowing farmers to efficiently manage water resources and optimize crop production. Overall, the versatility and reliability of hydraulic solenoid valves make them a vital component across diverse industrial applications.

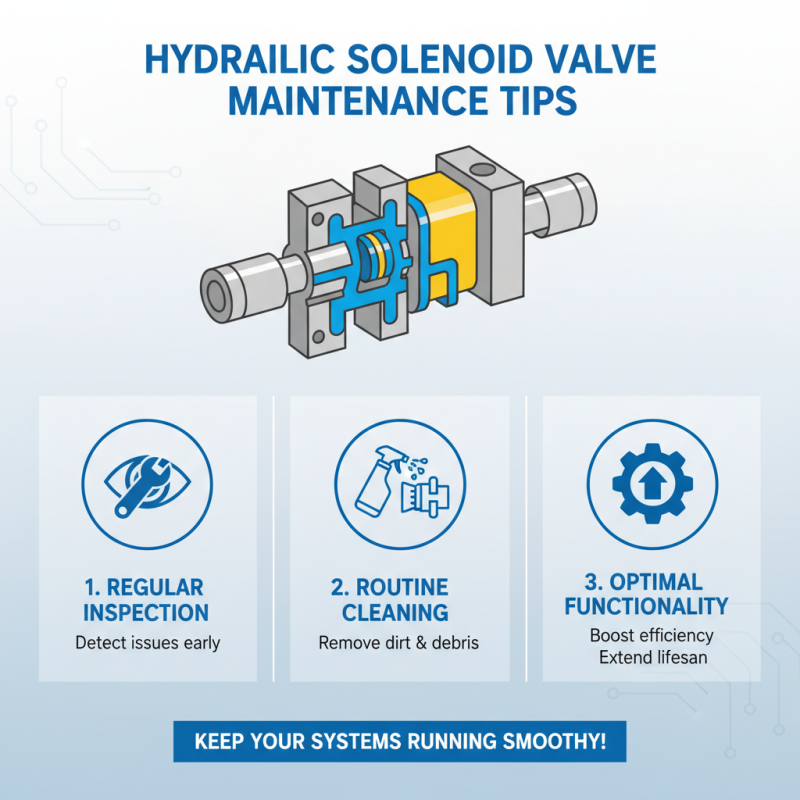

Maintenance Tips for Ensuring Optimal Functionality of Solenoid Valves

Proper maintenance of hydraulic solenoid valves is crucial for ensuring their optimal functionality and longevity. Regularly inspecting these valves can help detect issues before they escalate into more significant problems. One of the most important tips is to routinely clean the valves to remove dirt and debris that can obstruct the flow or cause malfunction. A clean solenoid valve will operate more efficiently and reduce the likelihood of failures.

Another key aspect of maintenance is checking the electrical components of the solenoid valve. Loose connections or wear on the wiring can lead to inconsistent performance or complete failure. It’s advisable to perform regular electrical tests to ensure that power is being supplied correctly and the coils are functioning without interruptions. Additionally, replacing any worn seals or gaskets can prevent leaks and maintain pressure within the hydraulic system.

Lastly, keeping an eye on the operating environment is essential for the longevity of solenoid valves. Extreme temperatures or exposure to corrosive substances can adversely affect their performance. Implementing protective measures, such as insulation or using protective coatings, can significantly enhance the durability of solenoid valves. Regularly updating maintenance schedules based on the environment and usage can lead to improved performance and reduced downtime.

Related Posts

-

How to Choose the Right Hydraulic Solenoid Valves for Your Applications

-

How to Choose the Right Hydraulic Check Valve for Your System

-

Unlocking Efficiency: How Hydraulic Directional Control Valves Boost Industrial Performance by 30%

-

Understanding the Essential Role of Continental Hydraulic Valves in Modern Industry

-

How to Choose the Right Hydraulic Valves for Your Industrial Needs

-

Exploring the Future of Hydraulic Control Valves at the 2025 China Import and Export Fair

skip to Main Content

skip to Main Content