Top Hydraulic Parts for Enhanced Performance in Machinery?

Hydraulic parts play a crucial role in enhancing the performance of machinery. According to a recent industry report by Market Research Future, the hydraulic components market is projected to grow at a compound annual growth rate of 6.6% through 2025. This growth is mainly driven by advancements in hydraulic technology and increased demand across various sectors, such as construction and agriculture.

Efficient hydraulic systems contribute to better energy management and operational efficiency. Research highlights that implementing optimized hydraulic parts can improve machinery productivity by 15%. However, maintenance challenges remain. Many companies overlook the importance of regular checks on hydraulic systems, resulting in unexpected downtime. This can hinder overall productivity, leading to significant financial losses.

Investing in high-quality hydraulic parts is vital for reliable machinery operation. Some manufacturers still face difficulties in sourcing durable components. This issue can lead to inferior performance and increased wear and tear on machines. Therefore, selecting the right hydraulic parts is essential for long-term success, despite the challenges in the market.

Importance of Hydraulic Parts in Machinery Performance

Hydraulic parts play a crucial role in machinery performance. They manage the transfer of energy, enabling efficient operation across various applications. Data from the Hydraulic Institute shows that well-functioning hydraulic components can improve efficiency by up to 20%. This is especially significant in industries like construction and manufacturing, where precise control and reliability are vital.

Failures in hydraulic systems can lead to costly downtime. Reports indicate that 30% of unplanned maintenance events are due to hydraulic component failures. Regular maintenance and timely replacement can mitigate these issues. Despite the importance, many operators overlook the signs of wear. Small leaks or unusual noises can indicate deeper problems that, if ignored, result in more severe failures.

Investing in high-quality hydraulic parts is essential for maximizing machinery performance. However, cost considerations can lead to shortcuts. Some companies may opt for cheaper alternatives that compromise reliability. This often leads to more expenses in the long run due to increased maintenance needs. Balancing cost with quality is a reflection point for many in the industry. Recognizing the value of reliable components could be the difference between consistent performance and operational disruptions.

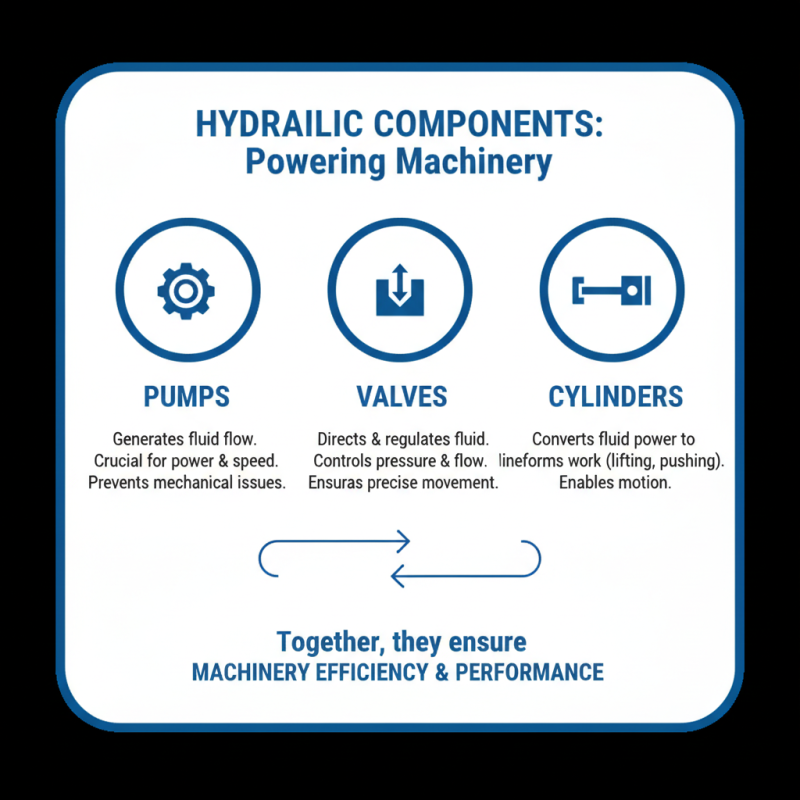

Key Types of Hydraulic Components for Optimal Operation

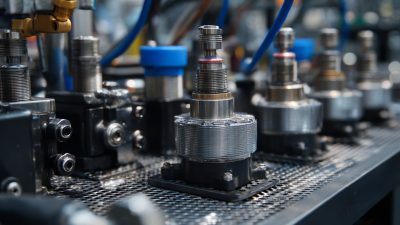

Hydraulic components play a vital role in machinery performance. Key types include pumps, valves, and cylinders. Each component serves a specific function that contributes to overall efficiency. Pumps generate hydraulic fluid flow. They are crucial for systems requiring power and speed. Inadequate pump selection can lead to reduced performance and mechanical issues.

Valves control the flow and direction of hydraulic fluid. They ensure that the right amount of fluid reaches each part of the machine. Using valves effectively can enhance response times. However, poor valve maintenance often leads to leaks and pressure drops, impacting operation.

Cylinders convert hydraulic energy into mechanical force. They are essential in lifting and pushing applications. A mismatch between cylinder size and machine needs can cause inefficiencies. Regular inspections and adjustments are necessary for optimal function. Each component plays a unique role in the hydraulic system. Ensuring they work together seamlessly is a challenge many operators face.

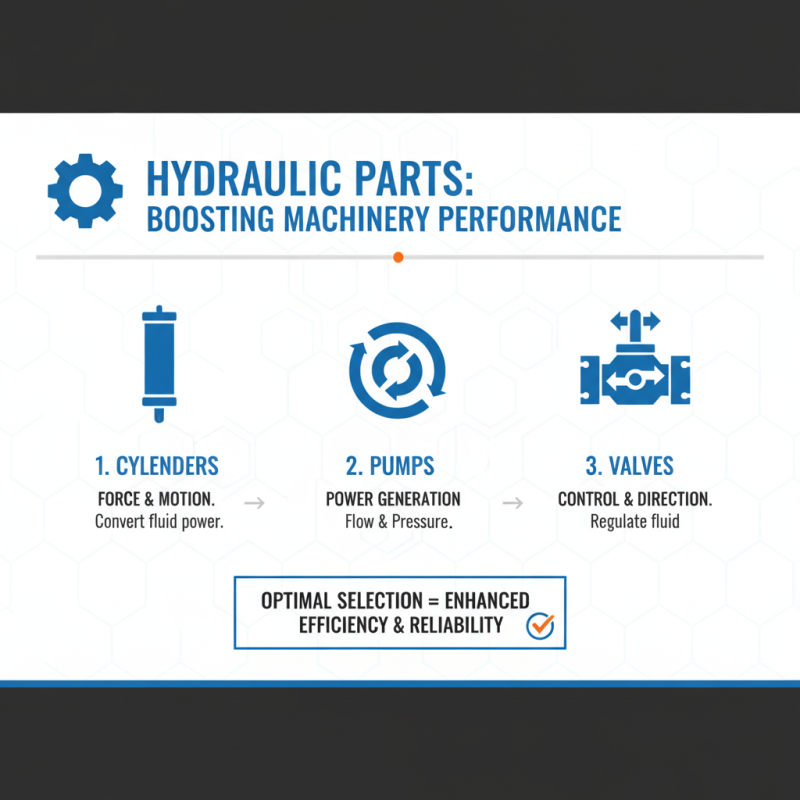

How to Select the Right Hydraulic Parts for Your Machinery

Choosing the right hydraulic parts can significantly enhance machinery performance. Various components play specific roles. Cylinders, pumps, and valves are essential. Each part needs careful selection based on your machinery's requirements.

Tips: Always check for compatibility. Sometimes, a part may fit physically but not function correctly. Research specifications thoroughly. Engage with hydraulic experts when uncertain. Their insights can save time and money.

Consider the working environment, too. High temperatures or humidity can affect part longevity. If your machinery operates in harsh conditions, better quality materials may be necessary. Maintaining a balance of cost and quality is crucial.

Don't overlook the importance of regular maintenance. Replacement parts should match existing ones in terms of performance and durability. Ignoring this can lead to inefficiencies. Reflect on your past choices—what worked, and what didn't? Continuous learning from experiences is key.

Maintenance Tips for Enhancing Hydraulic System Efficiency

Hydraulic systems are crucial for machinery performance. Regular maintenance enhances their efficiency significantly. Research shows that a well-maintained hydraulic system can improve performance by up to 30%. This highlights the benefit of proactive care and attention.

One effective tip for maintenance is regularly checking fluid levels. Low fluid levels can cause overheating and inefficiency. Ensure to inspect hoses and connectors for leaks. Even tiny leaks can lead to significant losses over time.

Additionally, filter changes are essential. Dirty filters restrict fluid flow, reducing system responsiveness. This can impact overall productivity. Regularly replace filters according to the manufacturer’s guidelines. Keep records of maintenance tasks. This helps identify recurring issues, allowing for better long-term planning. A systematic approach can save time and costs in the long run.

Future Trends in Hydraulic Technology for Improved Performance

The future of hydraulic technology is exciting. Innovations are on the rise, focusing on efficiency and sustainability. Advanced materials are being developed, enhancing component life and performance. This change reduces waste and improves energy usage. Hydraulics is becoming greener.

Tips: Regular maintenance is crucial. Ensure your hydraulic system is checked often. This helps avoid unexpected failures.

Smart technology is increasingly integrated into hydraulic systems. Sensors monitor performance in real-time. This data drives improvements and helps predict issues before they escalate. The information is gold. It can inform design changes and operational adjustments.

Tips: Train your team on new tech. Understanding data helps in making quick decisions.

Sustainability is key to future designs. Manufacturers are exploring biodegradable fluids and recyclable parts. These efforts will minimize the environmental impact of hydraulic systems. Change is necessary, but some solutions still need fine-tuning. Not all innovations will fit every application, leading to mismatched expectations.

Related Posts

-

What Are the Key Components of Hydraulics Products and Their Applications

-

Why Fluid Power Hydraulics Are Essential for Modern Industry

-

Exploring Hydraulic Continental Solutions at the 138th Canton Fair 2025 Trends and Market Data

-

Understanding the Power of Pneumatic and Hydraulic Systems in Modern Industry with Over 300 Billion USD Revenue

-

Exploring the Synergy of Pneumatic and Hydraulic Systems in Modern Industrial Applications

-

Why Understanding Hydraulic Parts is Essential for Your Machinery Efficiency

skip to Main Content

skip to Main Content