Top Hydraulic Flow Control Techniques for Efficient Systems?

Efficient hydraulic flow control is vital for modern industrial systems. In fact, a report from the International Journal of Fluid Power states that hydraulic systems account for approximately 20% of energy loss in various machines. Thus, optimizing hydraulic flow control can greatly enhance performance and reduce energy waste. Proper techniques lead to better responsiveness and increased system lifespan.

Several industries, including manufacturing and construction, rely heavily on hydraulic systems. According to the Hydraulic Institute, improper flow control can lead to significant downtime and costs. For example, poorly designed flow control systems can waste up to 30% of hydraulic energy. This highlights the need for innovative and effective hydraulic flow control methods.

While advancements are made, challenges remain. Many engineers struggle to strike the balance between efficiency and cost-effectiveness. Some traditional techniques may not meet modern demands. Therefore, exploring contemporary hydraulic flow control methods is essential for maximizing system efficiency and addressing these ongoing issues.

Overview of Hydraulic Flow Control in Systems

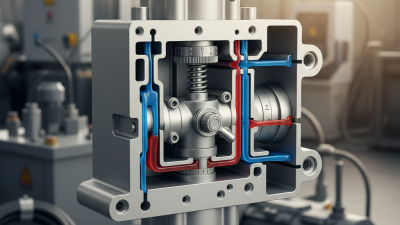

Hydraulic flow control is vital for optimal system performance. It manages the fluid dynamics in various applications, from industrial machinery to automotive systems. According to industry reports, effective flow control can lead to energy savings of up to 30%. This efficiency reduces operational costs and enhances productivity, making it essential for modern hydraulic systems.

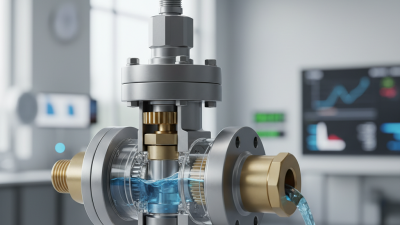

Flow control techniques vary widely. Proportional valves, for instance, enable precise adjustments in flow rates. They provide better responsiveness compared to traditional devices. However, improper calibration may hinder performance. Regular maintenance is crucial. Neglecting it can lead to increased wear and inefficiency.

Tips for better flow control: Monitor temperature and pressure regularly. These metrics help identify potential issues early. Consider using flow meters to track fluid movement accurately. Visual indicators can provide insights that prevent failures. Ignoring small anomalies might lead to larger, costly repairs later. Prioritizing proactive management can significantly enhance system reliability.

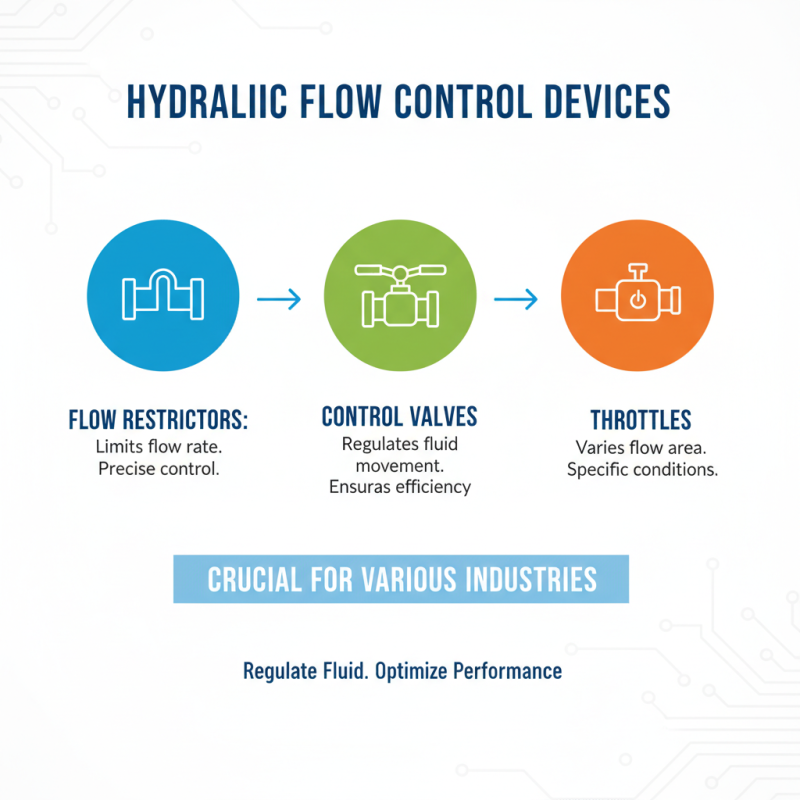

Types of Hydraulic Flow Control Devices and Their Applications

Hydraulic flow control devices play a crucial role in various industries. They regulate the movement of fluid and ensure efficiency. Common devices include flow restrictors, control valves, and throttles. Each type serves different purposes and operates under specific conditions. For instance, flow restrictors limit the flow rate. They are especially useful in applications where precise control is needed.

Control valves are widely used in hydraulic systems. According to recent industry reports, control valves account for approximately 40% of the market share in hydraulic components. These valves can adjust flow pressure and direction. Throttles, on the other hand, are less popular but still essential. Their simplicity makes them a viable option for basic flow control.

While many systems function well, not all are efficient. Often, there is room for improvement. Over time, wear and tear can compromise performance. Regular maintenance is necessary but often overlooked. Some systems also lack the sophistication to meet rising demands. Addressing these issues can lead to significant efficiency gains. Investing in modern flow control solutions may be beneficial in the long run.

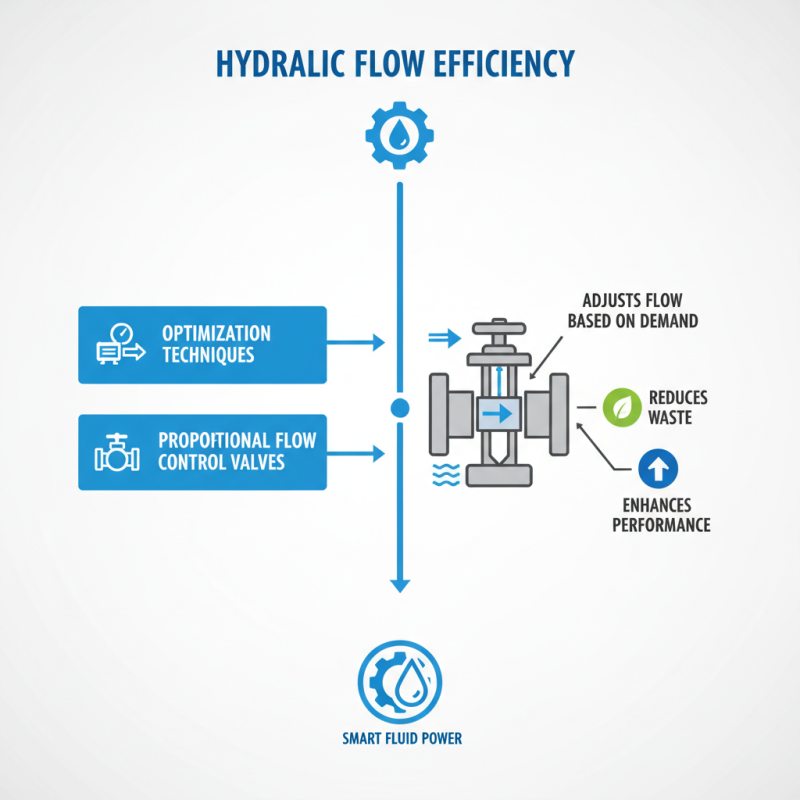

Key Techniques for Optimizing Hydraulic Flow Efficiency

Hydraulic flow efficiency is crucial in many systems. Several techniques can help optimize this efficiency. One effective method is the use of proportional flow control valves. These valves adjust the flow rate based on demand. They ensure systems utilize only the necessary amount of fluid. This reduces waste and enhances performance.

Another valuable technique involves system design elements like pipe sizing. Incorrectly sized pipes can lead to pressure drops. This impacts flow rates significantly. Using properly sized pipes boosts the system's overall effectiveness. Regular maintenance is also essential. Dirty filters or worn components can hinder performance. Attention to these details can make a noticeable difference.

Hydraulic accumulators offer an alternative approach. They store energy and release it when needed, improving flow consistency. However, their integration requires careful consideration of system dynamics. Mistakes in design can lead to inefficiencies. Optimizing hydraulic flow involves a balance of technology and vigilant oversight. Every team should consider these factors continuously.

Factors Influencing Hydraulic Flow Control Performance

Hydraulic flow control is critical for system efficiency. Several factors affect performance, and understanding them is vital. One key aspect is fluid viscosity. If it’s too high, flow becomes sluggish. Conversely, low viscosity can lead to leaks and reduced control.

Another influencing factor is system temperature. Elevated temperatures can decrease fluid density. This creates challenges in maintaining consistent flow rates. In addition, component wear can alter the effectiveness of flow control. Over time, seals and valves wear down. This leads to inefficiencies and potential failures.

Environmental conditions also play a role. For instance, installing components outdoors exposes them to varying temperatures. This can affect the hydraulic system's response time. Regular maintenance is essential. Neglecting small issues can lead to larger problems. Striking a balance between these factors is key for optimal performance.

Future Trends in Hydraulic Flow Control Technologies

The future of hydraulic flow control technologies is exciting. A recent report by the Fluid Power Institute suggests that demand for more efficient systems will rise by 20% over the next five years. This pushes manufacturers to innovate continually and adopt advanced techniques. One promising area is digital flow control. Digital systems can optimize performance in real-time, reducing energy consumption.

Moreover, AI-driven analytics are becoming valuable. These tools help monitor flow rates continuously. They detect anomalies faster than traditional methods. Data shows that predictive maintenance can cut downtime by up to 30%. However, many companies struggle to implement these technologies. Staff training and integration with existing systems pose significant challenges.

Additionally, the push for sustainability can’t be ignored. Hydraulic systems must adapt to stricter environmental regulations. Bio-based fluids are gaining traction; they offer less harmful effects. However, their performance can vary significantly. This inconsistency raises questions about reliability in high-stress applications. The industry must balance innovation with proven techniques. This balance will be crucial in navigating the future of hydraulic flow control.

Top Hydraulic Flow Control Techniques for Efficient Systems

This chart illustrates the efficiency ratings of various hydraulic flow control techniques, showcasing their effectiveness in modern systems. Proportional valves lead with the highest rating, followed by pressure compensated flow control. Trends indicate a growing interest in smart technologies enhancing efficiency.

Related Posts

-

Ultimate Guide to Mastering Hydraulic Flow Control Techniques for Optimal Performance

-

7 Essential Tips for Effective Hydraulic Flow Control in Your System

-

Addressing Common Hydraulic Flow Control Challenges: Insights and Data from Industry Experts

-

Why Hydraulic Flow Control Valves Are Essential for Optimal Machinery Performance

-

Top 10 Hydraulic Controls You Need to Know for Optimal Performance

-

The Ultimate Guide to Pressure Regulating Valves and Their Applications

skip to Main Content

skip to Main Content