Top 10 Hydraulic Controls You Should Know About?

In the world of hydraulic controls, understanding the fundamentals is crucial. Renowned expert Dr. John Smith once stated, “Mastering hydraulic controls opens doors to efficiency and precision in every application.” This insight reflects the significance of the right hydraulic controls in various industries.

Hydraulic controls manage fluid power systems effectively. They are vital in construction, manufacturing, and automotive sectors. These controls directly influence performance, safety, and productivity. Yet, many overlook their complexity. For instance, a simple valve failure can halt an entire operation. Understanding how each component works is essential.

Exploring the top hydraulic controls can enhance your operational knowledge. These ten controls stand out for their efficiency. However, it's important to remember that every system has limitations. Recognizing these can lead to better decision-making. Hydraulic technology plays a central role in modern machinery. Emphasizing the importance of these controls is not just informative; it’s necessary for progress.

Essential Concepts of Hydraulic Controls in Modern Engineering

Hydraulic controls are essential in modern engineering. They manage power transmission and control movement in various applications. These systems use fluid mechanics to create force. Understanding their concepts is crucial for effective design and operation.

One key concept is pressure regulation. It ensures systems operate efficiently. Accurate pressure reduces energy consumption. Many engineers overlook this, leading to system failures. Another important aspect is flow control. Valves adjust the flow rate, impacting overall performance. Inadequate flow can hinder operation, causing delays and increased wear on components.

Hydraulic actuators convert hydraulic energy to mechanical movement. They are used in machinery, airplanes, and automotive systems. The design of actuators can be complex. Engineers must consider factors like size, weight, and response time. This complexity often leads to oversights that affect reliability. Proper maintenance can mitigate some issues, but it requires regular attention. Ignoring these details can result in costly repairs and downtime.

Top 10 Hydraulic Controls You Should Know About

This chart illustrates the importance level of various hydraulic controls used in modern engineering. Each component plays a crucial role in the efficient operation of hydraulic systems.

Overview of Hydraulic Control Components and Their Functions

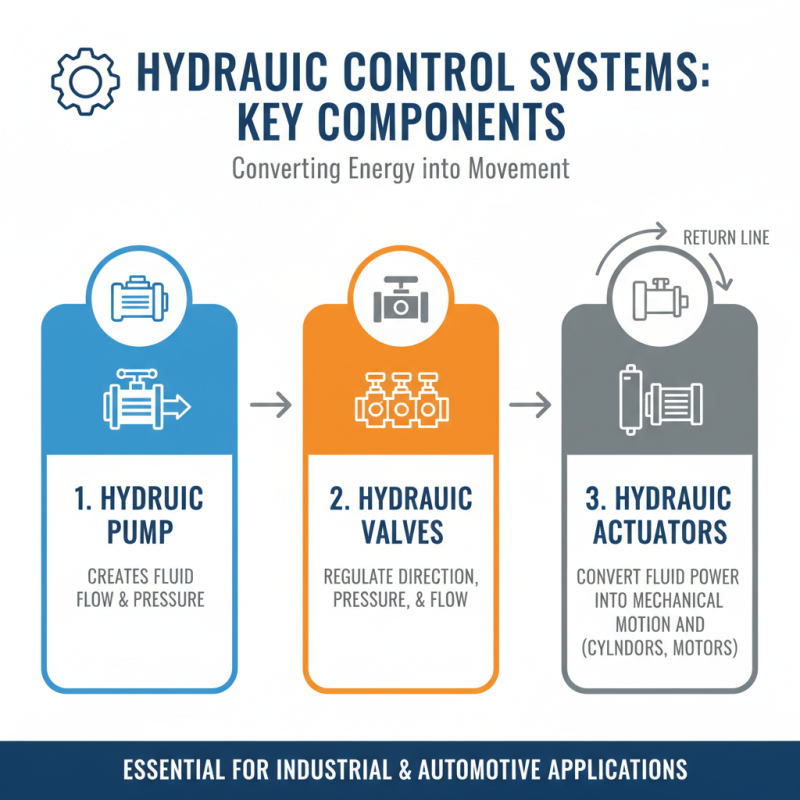

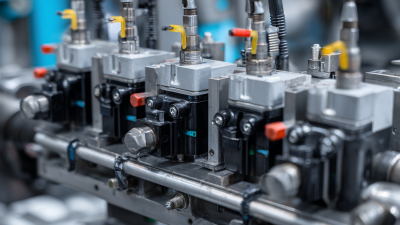

Hydraulic controls are essential in various applications, from industrial machinery to automotive systems. Understanding the components involved can deepen your appreciation of how these systems work. Key components include hydraulic pumps, valves, and actuators. Each plays a critical role in converting energy into movement.

Hydraulic pumps are the heart of the system. They generate flow and pressure to operate connected components. Valves control this flow, directing it to specific areas or shutting it off as needed. Actuators then convert hydraulic energy into mechanical movement. While these components seem straightforward, their integration can be complex. Improper alignment or leaks can lead to inefficient operation.

Another vital part is the hydraulic fluid. It acts as a medium for energy transfer. The choice of fluid can impact both performance and safety. Maintaining the fluid's quality is often overlooked but crucial. Contaminated fluid can degrade components. Regular checks and maintenance are often forgotten in busy work environments, leading to unexpected failures. Understanding these components can prevent such issues.

Key Types of Hydraulic Actuators and Their Applications

Hydraulic actuators are essential in various industries. They convert hydraulic energy into mechanical motion. This process enables machines to perform tasks with precision. Key types of hydraulic actuators include hydraulic cylinders and hydraulic motors.

Hydraulic cylinders are commonly used for linear motion. They are simple yet powerful devices. Often found in construction equipment, they lift heavy loads effectively. Hydraulic motors, on the other hand, provide rotational motion. You’ll see them in applications like conveyor systems and automotive machinery.

While hydraulic actuators are efficient, they can also present challenges. Leakage in hydraulic seals is a common issue. This can lead to reduced performance and increased maintenance costs. Furthermore, understanding the specific application for each actuator type is crucial. Not every hydraulic actuator fits every situation perfectly. Continuous learning and adaptation are necessary for optimal use.

Top 10 Hydraulic Controls You Should Know About

| Hydraulic Control Type | Description | Common Applications | Advantages |

|---|---|---|---|

| Directional Control Valves | Control the direction of fluid flow in a hydraulic system. | Hydraulic presses, machine tools. | Precise control, rapid response. |

| Pressure Relief Valves | Limit the maximum pressure in a hydraulic circuit. | Safety systems, hydraulic lifts. | Protects equipment from damage. |

| Flow Control Valves | Regulate the flow rate in hydraulic systems. | Excavators, forklifts. | Enables smooth operation and variable speed control. |

| Actuators | Convert hydraulic energy into mechanical movement. | Automated machinery, robotics. | High power-to-weight ratio, precise control. |

| Hydraulic Cylinders | Provide linear motion by converting hydraulic pressure into mechanical force. | Construction equipment, aircraft landing gear. | Strong lifting capabilities, compact design. |

| Hydraulic Pumps | Generate flow to facilitate hydraulic movement. | Industrial machinery, hydraulic systems. | Reliable energy source, versatile applications. |

| Hydraulic Accumulators | Store hydraulic energy for later use. | Pressurized systems, backup power sources. | Enhances system efficiency, reduces pressure fluctuations. |

| Hydraulic Filters | Remove contaminants from hydraulic fluid. | All hydraulic systems. | Promotes longevity of components, ensures system reliability. |

| Hydraulic Hoses & Fittings | Transport hydraulic fluid between components. | Construction, manufacturing machines. | Flexible, durable, suitable for high pressure. |

| Control Valves | Regulate pressure, flow, and direction in a hydraulic circuit. | Robotics, automated systems. | Highly responsive, can be automated. |

Understanding Hydraulic Valves: Types and Mechanisms

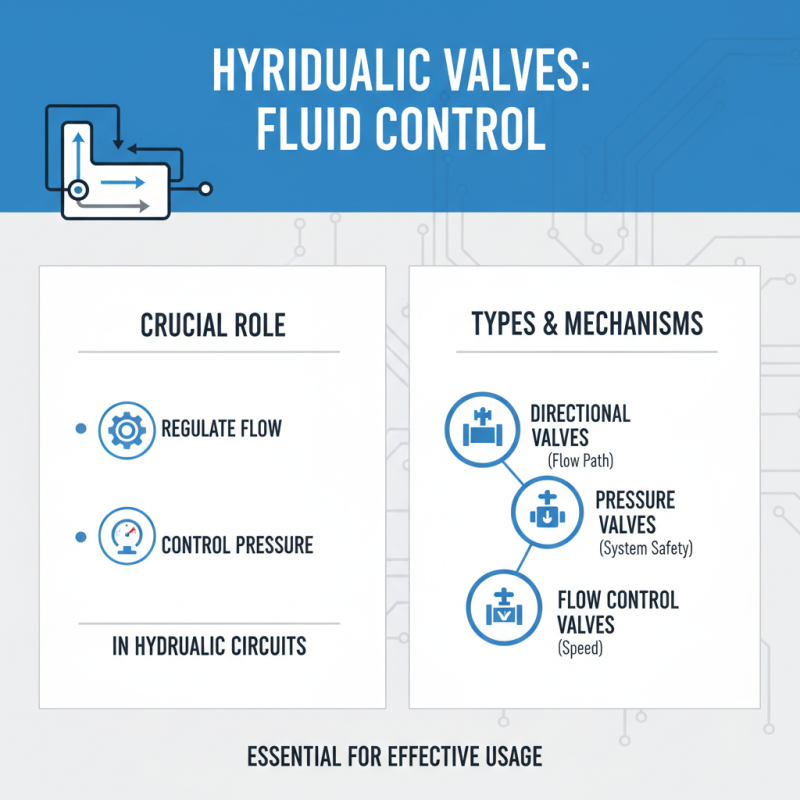

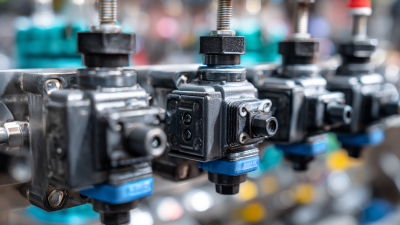

Hydraulic valves play a crucial role in fluid control systems. They regulate flow and pressure in hydraulic circuits. Understanding the different types and mechanisms is essential for effective usage.

There are several types of hydraulic valves. Directional control valves manage the path of fluid movement. Pressure relief valves safeguard systems from excessive pressure. Flow control valves, on the other hand, adjust the fluid flow rate, influencing speed. Each type has unique mechanisms that determine their functionalities.

Mechanisms can be complex. For example, a spool valve uses a sliding cylinder to control fluid flow. While highly efficient, this system can malfunction if not properly maintained. It's essential to regularly check connections and seals. Over time, wear can lead to leaks or reduced performance. Recognizing these imperfections can help improve system reliability. Continuous learning is vital as technology evolves.

Safety Considerations and Maintenance for Hydraulic Systems

Hydraulic systems are complex. They require careful attention to safety and maintenance. Regular checks can prevent accidents. Leaks often go unnoticed. It's crucial to inspect seals and hoses regularly. Look for cracks and wear. Small issues can lead to major failures.

Operator training is essential. Everyone should know how to handle hydraulic controls safely. Misuse can result in injury. Clear protocols for operation must be established. Regular refreshers can prevent complacency. Safety gear should always be worn.

Maintenance schedules should be followed meticulously. Components like filters and fluids need regular replacement. Contaminated fluid affects performance. Keep a log of inspections. Documentation helps identify recurring issues. Relying solely on intuition may not be enough. Regular reviews of the system can lead to improvements.

Related Posts

-

How to Optimize Hydraulic Flow Control for Maximum Efficiency

-

How to Choose the Right Hydraulic Valves for Your Industrial Needs

-

Exploring the Efficiency of Hydraulic Solenoid Valves: Industry Trends and Performance Data

-

Exploring the Future of Control Valves: Innovations and Trends Driving Efficiency in Industry

-

10 Essential Tips for Mastering Hydraulic Flow Control Techniques

-

Top 10 Hydraulic Controls You Need to Know for Optimal Performance

skip to Main Content

skip to Main Content