How to Select the Right Hydraulic Pressure Relief Valve for Your System Needs

Selecting the appropriate hydraulic pressure relief valves is crucial for ensuring the safety and efficiency of hydraulic systems across various industries. According to a report by MarketsandMarkets, the hydraulic valve market is projected to reach $12.96 billion by 2025, growing at a CAGR of 5.2%. This surge underscores the importance of choosing the right components, such as hydraulic pressure relief valves, which play a pivotal role in maintaining operational pressure and protecting equipment from potential damage due to overpressure conditions. Understanding the specific requirements of your hydraulic system, including flow rates, pressure ratings, and application conditions, is essential for optimizing performance and reliability. This guide aims to provide comprehensive insights into the selection process for hydraulic pressure relief valves, equipping engineers and system designers with the knowledge to make informed decisions and enhance their hydraulic systems' longevity and efficiency.

Understanding the Importance of Hydraulic Pressure Relief Valves in System Safety

Hydraulic pressure relief valves play a crucial role in maintaining the safety and functionality of hydraulic systems. These valves are designed to release excess pressure that could potentially lead to system failures or catastrophic accidents. By doing so, they protect essential components such as pumps, hoses, and cylinders from damage, ensuring the efficiency and longevity of the system. Understanding the importance of these safety devices is vital for anyone involved in the maintenance or operation of hydraulic machinery.

When selecting the right hydraulic pressure relief valve, it’s essential to consider factors such as the system's maximum operating pressure and the specific application requirements. One key tip is to consult with manufacturers or industry professionals to ensure that the chosen valve meets all safety standards and operational needs. Additionally, regular maintenance checks are crucial; ensure that the valve is functioning correctly and is free of any debris or wear that could hinder its performance.

Another tip is to assess the type of hydraulic fluid being used, as it can affect the valve's performance and compatibility. Ensure that the materials used in the valve construction are suitable for the fluid properties to avoid corrosion or degradation. By taking these factors into account, you can significantly improve the safety and reliability of your hydraulic system.

Identifying System Requirements for Pressure Relief Valve Selection

When selecting a hydraulic pressure relief valve, it is crucial to first identify the specific requirements of your hydraulic system. This involves understanding the operational parameters, such as maximum pressure, flow rates, and temperature ranges. Each of these factors plays a vital role in determining the appropriate valve specifications. For instance, if your system operates under high pressure but with low flow rates, a valve designed to handle such conditions will ensure optimal performance and safety.

When selecting a hydraulic pressure relief valve, it is crucial to first identify the specific requirements of your hydraulic system. This involves understanding the operational parameters, such as maximum pressure, flow rates, and temperature ranges. Each of these factors plays a vital role in determining the appropriate valve specifications. For instance, if your system operates under high pressure but with low flow rates, a valve designed to handle such conditions will ensure optimal performance and safety.

Additionally, consider the application context in which the relief valve will function. Different industries may impose unique constraints, such as regulatory compliance or environmental conditions. If the system is subjected to frequent fluctuations in pressure, a valve with adjustable settings might be necessary to accommodate these variations. Moreover, it’s essential to evaluate the materials used in the valve construction to ensure compatibility with the fluids in your system, thus preventing corrosion or degradation over time. By thoroughly assessing these system requirements, you can make a more informed decision when selecting the right hydraulic pressure relief valve for your needs.

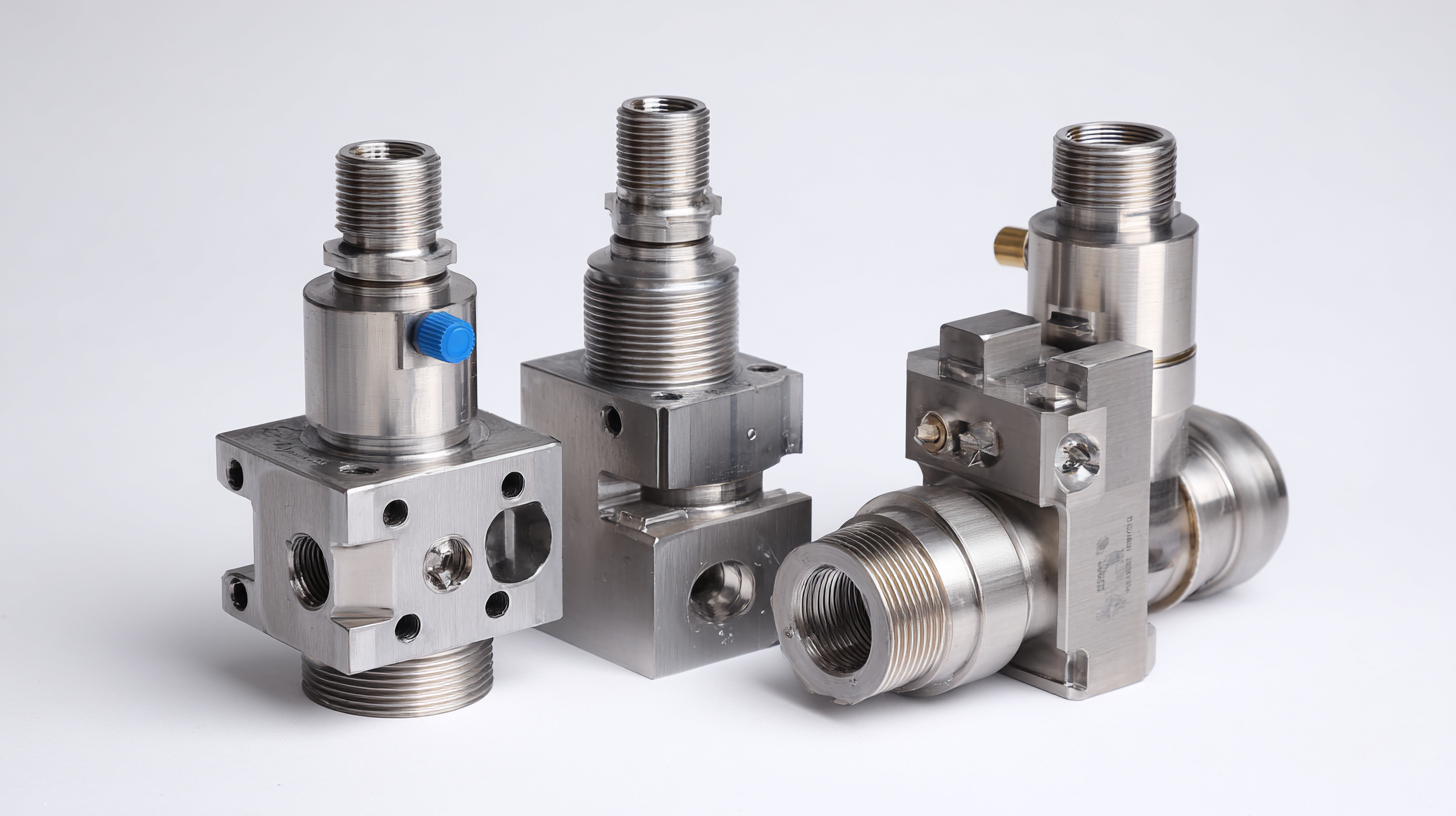

Evaluating Different Types of Hydraulic Pressure Relief Valves

When evaluating different types of hydraulic pressure relief valves, it’s crucial to understand their specific functionalities to choose the right one for your system. There are primarily two categories: direct-acting and pilot-operated valves. Direct-acting valves are simple and provide quick response times, making them ideal for smaller systems that require immediate relief. However, their capacity may be limited, which can be a disadvantage in larger, more complex setups.

On the other hand, pilot-operated valves utilize a smaller pilot valve to control the larger main valve, allowing for higher flow rates and improved pressure control. This type is generally more efficient for larger systems as they support greater pressure settings with less effort. When selecting a valve, consider the application requirements, as well as factors such as size, pressure range, and flow characteristics. Understanding the distinct advantages and limitations of each type will guide you in making an informed decision that best meets your hydraulic needs.

How to Select the Right Hydraulic Pressure Relief Valve for Your System Needs

| Valve Type | Pressure Range (psi) | Flow Rate (GPM) | Material | Applications |

|---|---|---|---|---|

| Spring-Loaded Relief Valve | 100 - 3000 | 20 | Steel | General hydraulic systems |

| Pilot-Operated Relief Valve | 500 - 5000 | 25 | Aluminum | High-pressure systems |

| Screw-Adjustable Relief Valve | 150 - 3500 | 15 | Stainless Steel | Food processing |

| Electro-Hydraulic Relief Valve | 200 - 4000 | 30 | Bronze | Robotics and automation |

Key Specifications to Consider When Choosing a Pressure Relief Valve

When selecting a hydraulic pressure relief valve, there are several key specifications to consider that can significantly impact the efficiency and safety of your system. One of the primary factors is the pressure setting, which should align with the specific requirements of your application. This involves evaluating the maximum system pressure and ensuring that the relief valve can release pressure effectively without causing damage or operational issues. Additionally, it’s important to consider the sizing of the valve, as undersized valves may not handle the required flow, while oversized valves can lead to overpressure situations.

Another critical specification is the material and construction of the valve. Depending on the operating environment, moisture resistance, temperature extremes, and potential chemical exposure can influence the choice of materials. Selecting a valve made from durable materials suitable for your application helps ensure longevity and reliability. Lastly, the response time of the valve is essential for maintaining system stability. A valve that reacts quickly to pressure changes helps prevent system failures and enhances overall performance. By carefully evaluating these specifications, you can choose the right hydraulic pressure relief valve tailored to meet your system's needs.

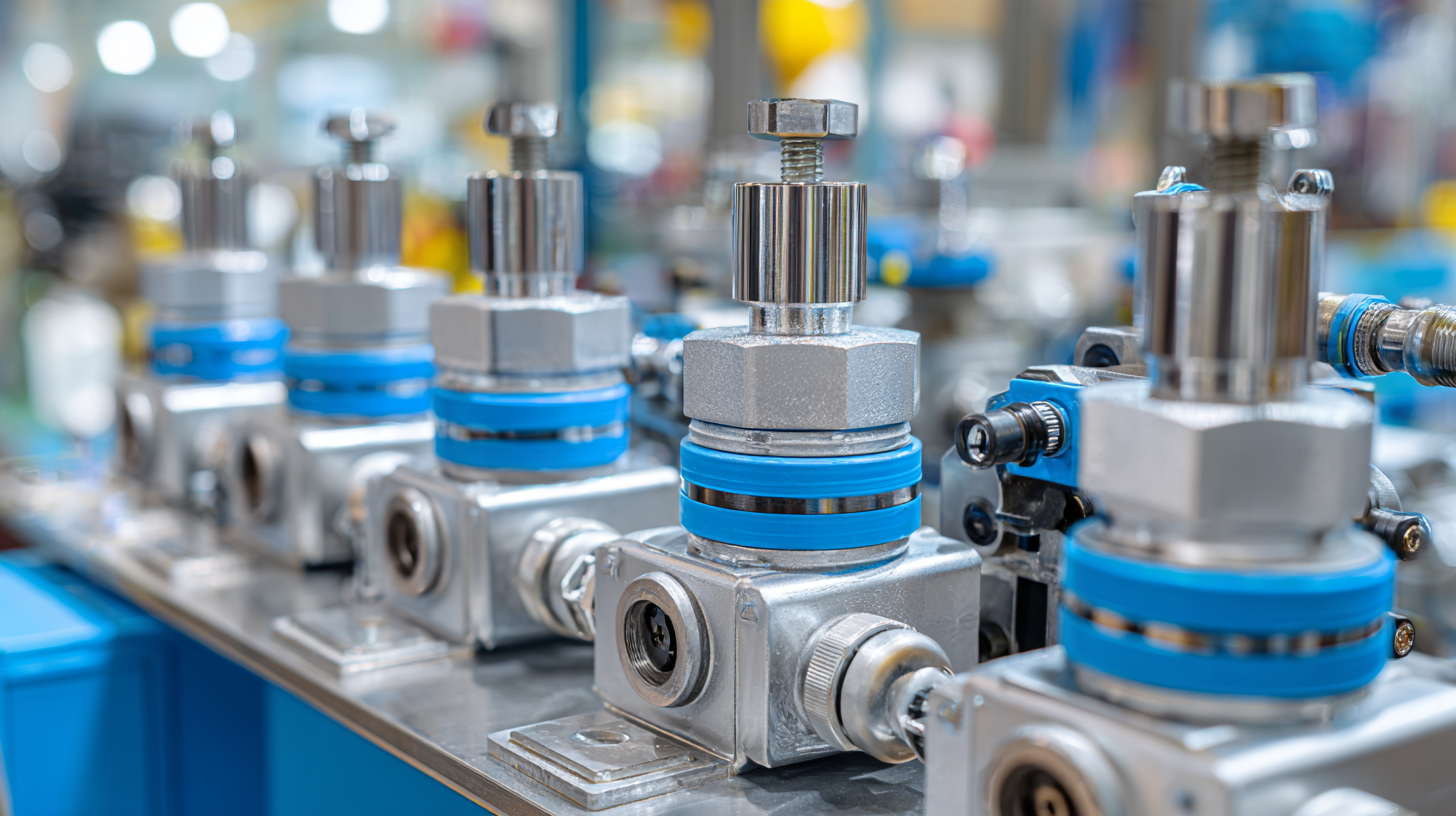

Installation and Maintenance Tips for Optimal Performance of Relief Valves

Proper installation and maintenance of hydraulic pressure relief valves are crucial for ensuring optimal performance and longevity. When installing a relief valve, it is essential to position it correctly within the system to allow for effective pressure release. This typically involves placing the valve close to the pump output or the actuator to minimize pressure losses. Utilizing the manufacturer’s guidelines for torque specifications and ensuring appropriate sealing methods will help prevent leaks and ensure a secure fit. It is also advisable to install the valve in a vertical orientation, if possible, to encourage the effective operation of the valve mechanics.

Regular maintenance is vital for the reliability of hydraulic pressure relief valves. It is recommended to conduct periodic inspections to check for wear and corrosion. Operators should verify the valve's set pressure and functionality, testing for proper operation under load conditions. Documenting performance data over time can provide valuable insights into the valve's condition and help identify potential issues early on. Additionally, flushing the hydraulic system regularly will help prevent contamination, which can adversely affect the valve's function. By following these installation and maintenance tips, users can ensure their hydraulic systems operate efficiently and safely.

Hydraulic Pressure Relief Valve Selection: Key Performance Metrics

Related Posts

-

Addressing Common Hydraulic Flow Control Challenges: Insights and Data from Industry Experts

-

7 Essential Tips for Maximizing the Life of Your Continental Hydraulic Pump

-

12 Key Reasons Why Directional Control Valves Are Essential for Efficient Fluid Power Systems

-

10 Tips for Choosing the Right Flow Valves for Your Business Needs

-

Ultimate Guide to Mastering Hydraulic Flow Control Techniques for Optimal Performance

-

How to Optimize Your System with Automated Valves for Maximum Efficiency

skip to Main Content

skip to Main Content