How to Optimize Your System with Automated Valves for Maximum Efficiency

In today's industrial landscape, optimizing system efficiency is paramount, and one of the most effective ways to achieve this is through the implementation of automated valves. According to a recent report by the International Society of Automation, systems utilizing automated valves can enhance operational efficiency by up to 30%, significantly reducing human error and increasing throughput. These smart devices not only enable real-time monitoring and control but also contribute to energy savings and reduced maintenance costs. As industries strive to meet growing demands while adhering to sustainability goals, integrating automated valves into process systems emerges as a strategic solution for maximizing efficiency and ensuring seamless operations. This guide will explore best practices for leveraging automated valves, detailing how they can transform your operational capabilities.

Understanding the Role of Automated Valves in System Optimization

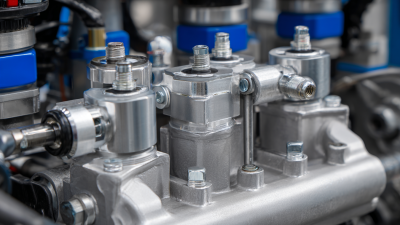

Automated valves play a crucial role in optimizing systems across various industries, enhancing efficiency and ensuring reliable operation. These smart components allow for precise control of fluid flow, pressure, and temperature within a system. By integrating sensors and actuators, automated valves provide real-time monitoring and adjustments, which helps to minimize waste and energy consumption while maintaining optimal working conditions.

Automated valves play a crucial role in optimizing systems across various industries, enhancing efficiency and ensuring reliable operation. These smart components allow for precise control of fluid flow, pressure, and temperature within a system. By integrating sensors and actuators, automated valves provide real-time monitoring and adjustments, which helps to minimize waste and energy consumption while maintaining optimal working conditions.

Furthermore, the implementation of automated valves contributes to improved safety and reduced operational costs. Unlike manual valves that require human intervention, automated systems can operate autonomously based on pre-set parameters or dynamic feedback from the environment. This not only decreases the likelihood of human error but also ensures that the system operates at peak performance. The adaptability of automated valves allows facilities to respond swiftly to changing demands, ultimately leading to a more efficient and streamlined process.

Key Benefits of Implementing Automated Valves for Efficiency

Automated valves are revolutionizing the way industries manage fluid control, leading to significant improvements in operational efficiency. According to a report by Markets and Markets, the global automated valve market is projected to grow from $5.45 billion in 2020 to $8.06 billion by 2025, reflecting a CAGR of 7.89%. This growth indicates a strong trend towards automation in various sectors, driven by the need for reliability and reduced operational costs.

One of the key benefits of implementing automated valves is their ability to enhance system responsiveness and precision. By utilizing advanced control systems, automated valves can adjust flow rates and pressure with remarkable accuracy, minimizing waste. A study from the International Journal of Automation and Computing notes that automating valve operations can lead to a 20% reduction in energy consumption, thanks to optimized flow control and reduced mechanical wear. This not only contributes to lower operating costs but also supports sustainability initiatives by reducing the carbon footprint of industrial operations.

Moreover, automated valves facilitate real-time monitoring and data analytics, allowing companies to make informed decisions about maintenance and system adjustments. According to a Frost & Sullivan report, predictive maintenance enabled by smart valve technology can decrease downtime by up to 30%, ensuring that systems operate at peak efficiency and extending the lifespan of critical components. By adopting automated valve solutions, industries are poised to unlock unprecedented levels of efficiency while also enhancing safety and compliance.

Best Practices for Selecting the Right Automated Valves

When selecting the right automated valves, it's essential to consider several best practices to ensure optimal performance and efficiency. Firstly, understanding the specific requirements of your system, including media types, pressure and temperature ranges, can significantly influence the choice of valve. Opt for valves with suitable actuators that provide the necessary response time and control accuracy, especially in applications requiring rapid adjustments.

Additionally, examining the valve materials is crucial in preventing corrosion and ensuring durability. For systems that handle aggressive fluids or extreme temperatures, select valves made from high-quality, resilient materials that align with industry standards. Moreover, utilizing comprehensive resources such as the ISA-75 series can provide valuable guidance in choosing the right specifications and configurations for your automated valves, ensuring a product that meets both operational demands and cost-efficiency. By adhering to these best practices, you can effectively enhance the efficiency of your system through thoughtful valve selection.

Integrating Automated Valves with Existing Systems for Seamless Operation

Integrating automated valves into existing systems can significantly enhance operational efficiency and reduce manual oversight. The first step to seamless operation is conducting a comprehensive assessment of your current system. Identifying areas where automated valves can be advantageous is crucial; for instance, consider sections of the system that experience frequent adjustments or require precise control. This analysis will not only help you select the right type of automated valve but also ensure compatibility with your existing infrastructure.

Tip: During the integration process, prioritize a gradual implementation to minimize disruptions. Start with non-critical applications to test the automated valves' performance and adapt as needed. Additionally, maintain clear communication with your team about the changes being made to encourage smoother adaptation and troubleshooting.

Another essential aspect is proper training for personnel who will manage the automated systems. Familiarizing your team with the new technology and its operations will empower them to maximize the efficiency of the automated valves. Regular training sessions and updates on best practices can lead to better performance and troubleshooting capabilities.

Tip: Consider leveraging remote monitoring capabilities that come with many automated valve systems. This will allow for real-time data analysis and can help in proactive maintenance, ensuring that any potential issues are addressed before they escalate.

Automated Valves Impact on System Efficiency

Monitoring and Maintenance Strategies for Long-lasting Efficiency

Incorporating automated valves into industrial systems can significantly enhance operational efficiency, but ensuring their long-lasting performance hinges on robust monitoring and maintenance strategies. According to a 2021 report by the International Society of Automation, regular maintenance can increase valve lifespan by up to 30%, which translates to reduced replacement costs and minimized downtime. By utilizing real-time monitoring techniques, such as predictive maintenance analytics, operators can foresee potential issues before they escalate, leading to a more streamlined process and enhanced reliability.

Implementing a comprehensive maintenance strategy involves not just routine inspections but also leveraging data analytics to optimize valve operation. A study from the American Society of Mechanical Engineers highlighted that facilities employing automated monitoring systems reported a 25% decrease in energy consumption and a 15% reduction in overall maintenance costs. By integrating advanced sensor technology and data-driven insights, companies can ensure that their automated valves operate within optimal parameters, promoting efficient resource usage and extending the system’s operational life.

Related Posts

-

12 Key Reasons Why Directional Control Valves Are Essential for Efficient Fluid Power Systems

-

Ultimate Flow Valves Maintenance Checklist for Optimal Performance and Longevity

-

5 Best Fluid Power Hydraulics Solutions for Optimal Performance

-

7 Essential Tips for Choosing Hydraulic Flow Control Valves for Your Business

-

5 Essential Tips for Choosing the Right Hydraulic Units for Your Business

-

Essential Checklist for Selecting the Right Hydraulic Check Valves for Your Applications

skip to Main Content

skip to Main Content