10 Essential Tips for Mastering Hydraulic Flow Control Techniques

Hydraulic flow control is a critical component in modern industrial applications, impacting the efficiency and performance of various hydraulic systems. According to a recent report by the International Fluid Power Society (IFPS), the hydraulic industry is projected to grow by 6.5% annually, emphasizing the importance of mastering hydraulic flow control techniques in this expanding market. As industries increasingly rely on hydraulic systems for automation and precision, developing expertise in this area becomes essential for engineers and technicians alike.

Renowned hydraulic systems expert Dr. Emily Foster states, "Effective hydraulic flow control is the backbone of any successful hydraulic operation, enabling precise movement and control." Her insights reflect the pressing need for quality training and understanding in hydraulic technologies. Mastering these techniques is not only beneficial for enhancing system performance but also crucial for ensuring safety and reliability in operations. As we delve into the essential tips for mastering hydraulic flow control techniques, it is vital to recognize how these practices can lead to significant advancements in productivity and operational excellence across various sectors.

Understanding the Fundamentals of Hydraulic Flow Principles

Hydraulic flow control is a critical aspect of various industrial applications, directly influencing the efficiency and effectiveness of machinery. Understanding the fundamentals of hydraulic flow principles is essential for anyone looking to master these techniques. According to a report by the International Fluid Power Society (IFPS), approximately 75% of hydraulic system failures are attributable to improper flow control and management. This underscores the importance of grasping the basic principles of hydraulic flow, such as Bernoulli's equation and the concept of pressure differential.

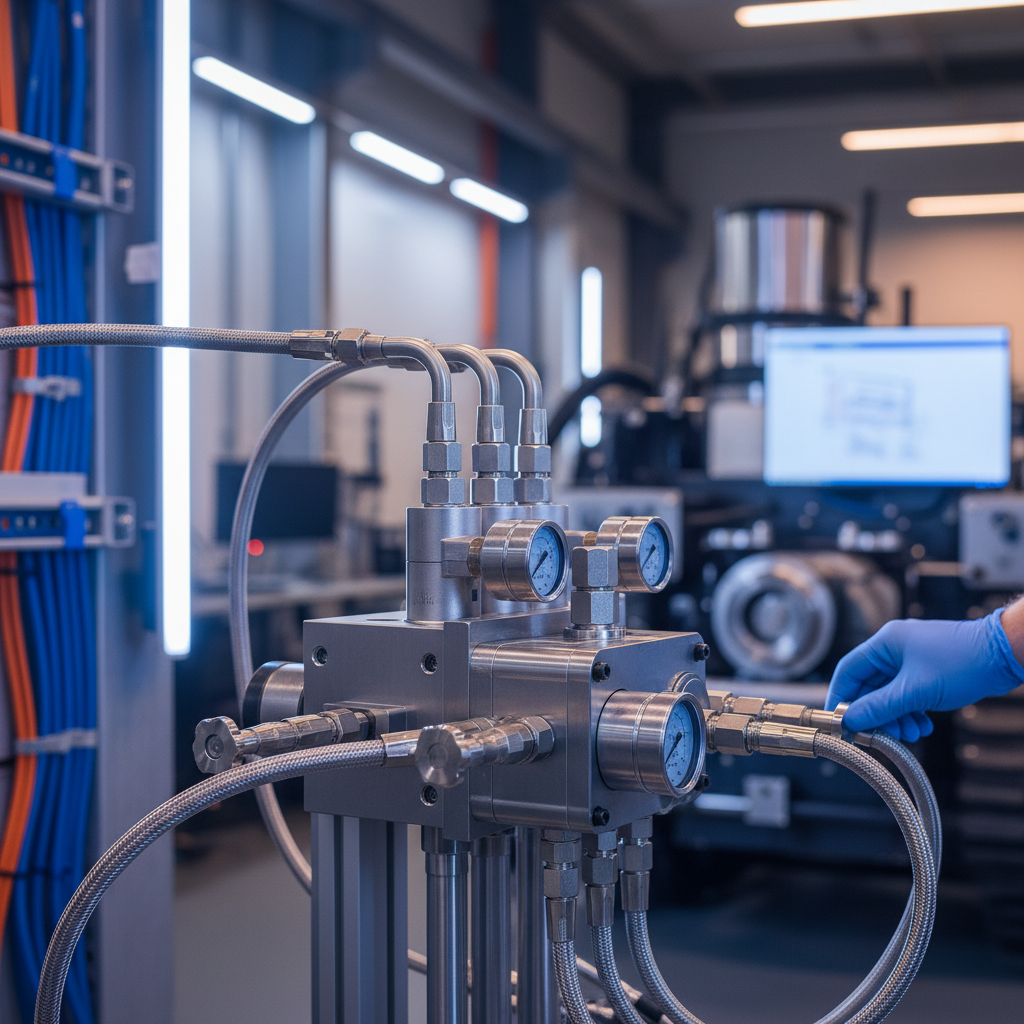

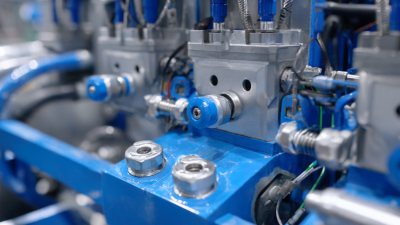

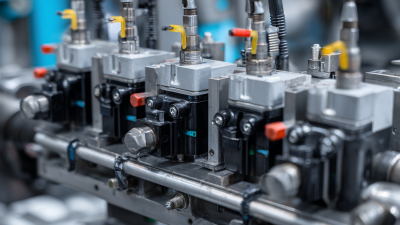

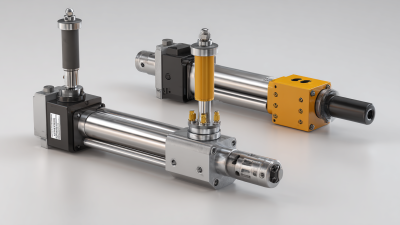

At the core of hydraulic flow control are key components like valves and pumps which regulate the fluid movement and pressure within the system. The correct selection and implementation of these components can lead to improved system performance and reduced energy consumption. Research indicates that systems optimized for hydraulic flow can attain efficiencies exceeding 90%, significantly lowering operational costs. Furthermore, the ability to manipulate flow rates and pressure settings enhances responsiveness and precision in various applications, from mobile equipment to manufacturing processes. Fostering a deep understanding of these fundamentals is vital for engineers and technicians aiming to innovate and enhance hydraulic system designs.

Analyzing the Role of Valves in Flow Control Efficiency

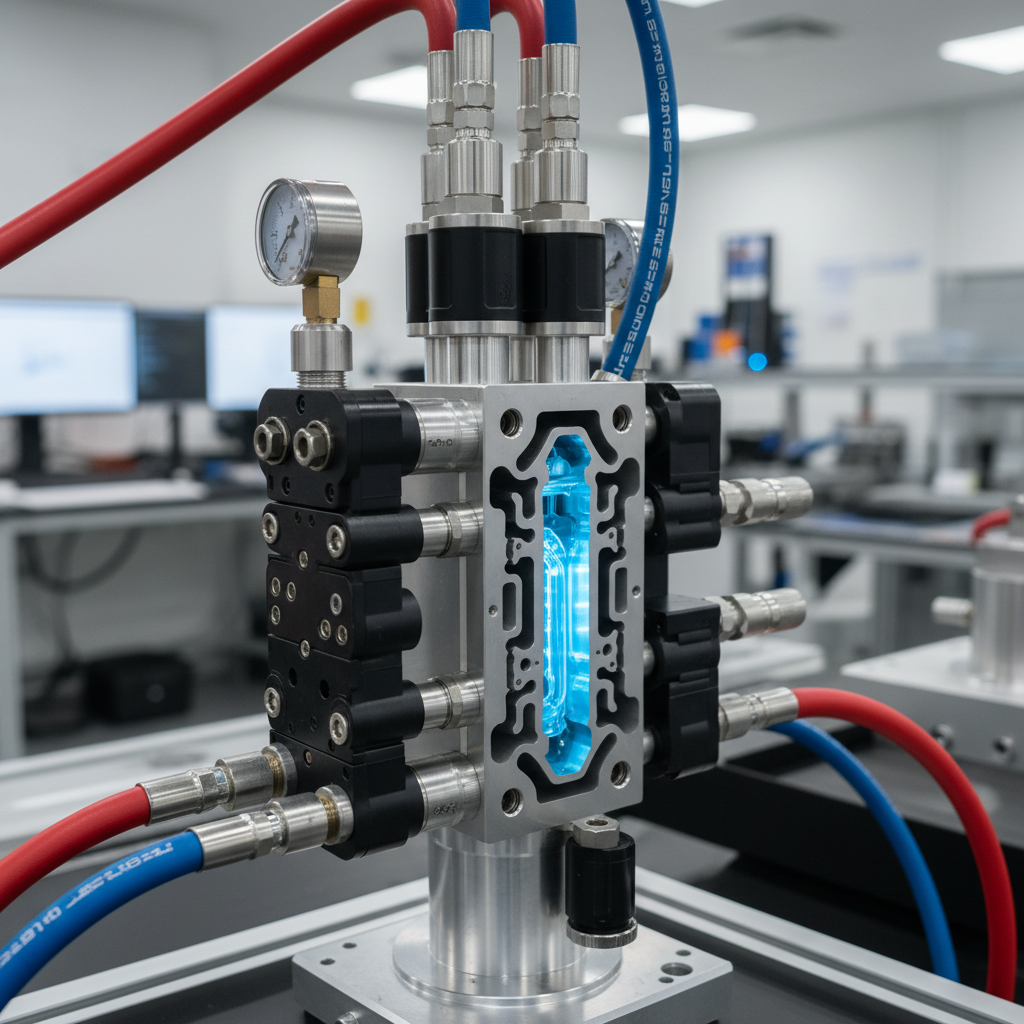

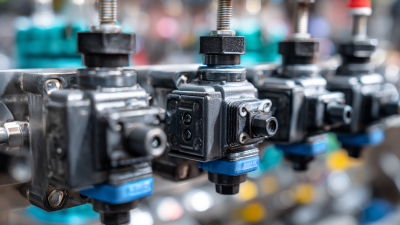

Hydraulic flow control is fundamental in various industrial applications, where precision and efficiency are paramount. Valves play a critical role in this context, acting as gatekeepers that regulate fluid movement within a hydraulic system. Their design and functionality directly impact the overall efficiency of flow control techniques. By modulating the flow rate and pressure, valves ensure that systems operate within their optimal parameters, preventing issues such as cavitation and overheating.

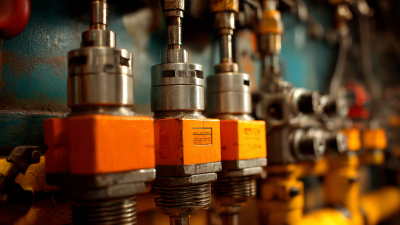

Understanding the different types of valves—such as relief, proportional, and directional control valves—is essential for mastering hydraulic flow control. Each type serves a specific purpose and employs distinct mechanisms to achieve desired flow characteristics. For instance, proportional valves allow for gradual adjustments in flow, which is crucial in applications requiring delicate movements. Conversely, relief valves are vital for safeguarding systems from excessive pressure, thereby enhancing the longevity and reliability of hydraulic equipment. Analyzing the interplay between these valves and flow dynamics reveals the intricate balance necessary for achieving high efficiency and performance in hydraulic systems.

Implementing Effective Flow Control Strategies in Hydraulic Systems

Implementing effective flow control strategies in hydraulic systems is crucial for optimizing performance and ensuring system reliability. By understanding the principles of hydraulic flow, engineers can design systems that efficiently control pressure and flow rates. One of the essential strategies is the use of proportional valves. These valves allow for fine control over hydraulic fluid flow, enabling smoother operation and precise adjustments in real-time. By integrating proportional technology, systems can respond dynamically to varying load conditions, minimizing energy consumption and reducing wear on components.

Another vital aspect of hydraulic flow control is the maintenance of hydraulic fluid cleanliness. Contaminants in hydraulic fluids can lead to wear and tear on components and significantly impact flow efficiency. Implementing proper filtration systems and conducting regular maintenance checks ensures that the hydraulic fluid remains clean, thus prolonging the life of the system and maintaining its performance. Furthermore, employing advanced diagnostics tools can help monitor flow conditions and detect potential issues before they escalate, ensuring that flow control strategies are implemented proactively rather than reactively, leading to more efficient operation overall.

Troubleshooting Common Hydraulic Flow Control Issues

Hydraulic flow control systems are essential for various industrial applications, but they often encounter common issues that can disrupt operations. One frequent problem is low flow rates, usually caused by blockages or restrictions in the system. To troubleshoot this, inspect the hydraulic lines and filter systems for obstructions that may impede fluid movement. Additionally, check the pump for efficiency; a malfunctioning pump can significantly reduce flow rates. Regular maintenance and periodic inspections can help identify potential issues before they escalate.

Another common challenge is excessive noise, which can indicate problems such as cavitation or air contamination in the hydraulic fluid. Cavitation often arises from inadequate fluid supply or high pressure fluctuations, leading to pressure drops. To address this, ensure the system maintains a consistent and adequate fluid supply, and consider installing pressure-reducing valves if necessary. Furthermore, air contamination can be mitigated by introducing proper venting systems and maintaining the integrity of the hydraulic fluid reservoir. Promptly addressing these issues not only enhances system performance but also prolongs the lifespan of hydraulic components.

Another common challenge is excessive noise, which can indicate problems such as cavitation or air contamination in the hydraulic fluid. Cavitation often arises from inadequate fluid supply or high pressure fluctuations, leading to pressure drops. To address this, ensure the system maintains a consistent and adequate fluid supply, and consider installing pressure-reducing valves if necessary. Furthermore, air contamination can be mitigated by introducing proper venting systems and maintaining the integrity of the hydraulic fluid reservoir. Promptly addressing these issues not only enhances system performance but also prolongs the lifespan of hydraulic components.

Optimizing System Performance Through Regular Maintenance Techniques

Regular maintenance techniques play a critical role in optimizing hydraulic flow control systems. Effective maintenance not only enhances system reliability but also ensures peak performance. According to industry reports, the global gas turbine maintenance, repair, and overhaul (MRO) market is projected to reach a value of $15.09 billion in 2024, with consistent growth anticipated, reaching $18.23 billion by 2032. This trend underscores the importance of routine inspections and proactive maintenance strategies in preserving the functionality of hydraulic systems.

In sectors such as oil and gas refining, maintenance services are equally essential. The market for oil and gas refining maintenance services is expected to grow from $3.89 billion in 2025 to $5.1 billion by 2032, maintaining a compound annual growth rate of 3.93%. This growth highlights a growing recognition of the value of regular system check-ups and the implementation of efficient hydraulic flow control techniques, which can significantly reduce downtime and operational costs. By prioritizing maintenance, organizations can improve their hydraulic systems' accuracy and efficiency, ultimately leading to better overall performance.

Related Posts

-

How to Optimize Hydraulic Flow Control for Maximum Efficiency

-

5 Essential Tips for Choosing the Right Hydraulic Units for Your Business

-

How to Choose the Right Hydraulic Valves for Your Industrial Needs

-

Exploring the Efficiency of Hydraulic Solenoid Valves: Industry Trends and Performance Data

-

Essential Guide to Understanding Hydraulics Products for Everyday Applications

-

Exploring the Future of Control Valves: Innovations and Trends Driving Efficiency in Industry

skip to Main Content

skip to Main Content