2026 How to Master Hydraulic Flow Control Techniques?

In the dynamic world of hydraulic systems, mastering hydraulic flow control is essential. Expert engineer John Smith states, “Effective flow management is the backbone of efficient hydraulics.” This quote resonates with many professionals in the industry, underscoring the significance of flow control techniques.

Hydraulic flow control involves managing the fluid movement through various components. Precision in this area can determine the efficiency of entire systems. Many practitioners struggle with balancing speed and pressure. It requires keen observation and frequent adjustments. Mistakes in this field often lead to costly downtime or equipment failures. Thus, a thorough understanding of flow control principles is vital.

Professionals must reflect on their approaches. Are the techniques up to date? Continuous learning and adaptation are crucial. The landscape of hydraulic technology is always evolving. Therefore, refining flow control techniques is not just beneficial; it's necessary. Embracing change and learning from failures can lead to mastery in hydraulic flow control.

Understanding Hydraulic Flow Basics: Principles and Terminology

Understanding hydraulic flow is crucial for effective control techniques. Hydraulic systems rely on fluid movement to perform tasks. The flow of liquid determines how well machines operate. Key concepts include pressure, flow rate, and the properties of fluids. Each element plays a unique role in the overall performance. For example, low pressure might lead to insufficient power. High pressure, on the other hand, can cause damage.

Fluid dynamics is complex. It has many variables. Every fluid behaves differently under various conditions. Understanding viscosity is essential. It affects how fluids flow. Incorrect assumptions about fluid behavior can lead to failures. Small mistakes can create significant issues. A common error is ignoring temperature changes. Temperature affects viscosity. This can alter flow rates.

Terminology can be confusing. Terms like laminar and turbulent flow often arise. Laminar flow is smooth and orderly. Turbulent flow is chaotic and irregular. Recognizing the difference is vital. Misinterpreting these concepts can hinder progress. It invites challenges during analysis. Mastery of these basics lays the groundwork for advanced techniques. Taking time to grasp these principles is worth it. When fundamentals are clear, complex tasks become manageable.

Hydraulic Flow Control Techniques

This chart illustrates various hydraulic parameters essential for mastering hydraulic flow control techniques, showcasing how factors like flow rate, pressure, oil temperature, viscosity, and actuator speed can impact overall system performance.

Key Components of Hydraulic Systems: Pumps, Valves, and Actuators

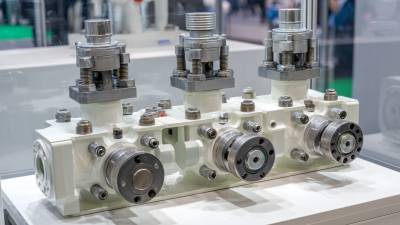

Hydraulic systems rely heavily on three key components: pumps, valves, and actuators. Each part plays a crucial role in controlling hydraulic flow. Pumps convert mechanical energy into hydraulic energy. They create the flow needed to move fluids throughout the system. Without pumps, nothing happens. However, choosing the right pump for the application can be challenging. Oversized or undersized pumps may lead to inefficiencies.

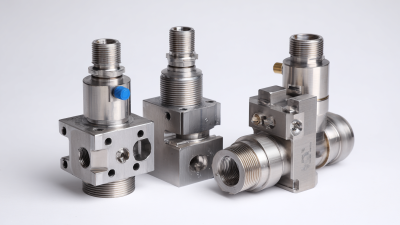

Valves manage the flow and pressure within hydraulic systems. They can be directional, pressure-regulating, or flow control valves. Each type serves a specific purpose. Directional valves control the path of the hydraulic fluid. Pressure-regulating valves prevent system overload. Flow control valves allow fine-tuning of the speed of actuators. Complexities arise when integrating these valves. One wrong choice can derail the entire operation.

Actuators are the final component in hydraulic systems. They convert hydraulic energy back into mechanical motion. Cylinders and motors are common types of actuators. While they seem straightforward, their installation can be tricky. Misalignment can cause wear and tear, leading to costly repairs. Understanding these components is vital for mastering hydraulic flow control. Each part has its strengths and weaknesses. Learning from mistakes in these areas is key to improvement.

Flow Control Techniques: Throttle, Bypass, and Proportional Control

Flow control techniques are crucial in hydraulic systems. Three main methods stand out: throttle, bypass, and proportional control. Each offers unique benefits and challenges. Understanding these can improve system efficiency and response.

Throttle control involves adjusting the flow by restricting it. This method can be straightforward but may lead to pressure drops and flow inconsistencies. Many overlook the importance of maintaining optimal flow rates. Often, a small adjustment can make a big difference.

Bypass control, on the other hand, allows excess fluid to divert. This technique can prevent overheating and protect sensitive components. Yet, it requires careful calibration. Over-reliance on bypass systems can cause inefficiencies.

Lastly, proportional control offers precise flow adjustments. It balances responsiveness with power consumption. Still, its complexity demands regular maintenance and expert knowledge. Proper training is essential for managing this technique efficiently.

Industry Standards: ISO & SAE Flow Measurement and Testing Procedures

Hydraulic flow control is critical in various industries. To ensure precision, adherence to standards is vital. ISO and SAE provide frameworks for flow measurement and testing procedures. According to the ISO 4413, proper flow assessment can lead to reduced system failures by 30%. This data highlights the necessity for compliant practices.

Many technicians overlook specific testing protocols. For instance, flow rate calibration is often done inaccurately. It is essential to regularly calibrate measurement devices to prevent performance degradation. A common oversight is neglecting to account for temperature variations, which can affect viscosity and flow rates. Understanding these nuances can enhance accuracy.

Tips for effective flow control include regular training on relevant standards. Keep updated with the latest ISO and SAE revisions. Recognize that even minor discrepancies can lead to significant issues in fluid dynamics. Make sure to document all testing results meticulously. This practice creates a reliable history for future reference and analysis.

2026 How to Master Hydraulic Flow Control Techniques? - Industry Standards: ISO & SAE Flow Measurement and Testing Procedures

| Dimension | Measurement Standard | Testing Procedure | Typical Range | Comments |

|---|---|---|---|---|

| Flow Rate | ISO 4401 | Flow Meter Calibration | 1-200 L/min | Critical for system performance |

| Pressure | SAE J1349 | Pressure Test Setup | 50-300 bar | Ensures system integrity |

| Temperature | ISO 4407 | Thermal Testing | -40 to 100 °C | Affects fluid viscosity |

| Fluid Contamination | ISO 4406 | Contamination Assessment | Class 1-24 | Key to system longevity |

| Cavitation | SAE J1823 | Cavitation Testing | Visual & Acoustic Monitoring | Indicates potential damage |

Case Studies: Optimizing Hydraulic Flow in Real-World Applications

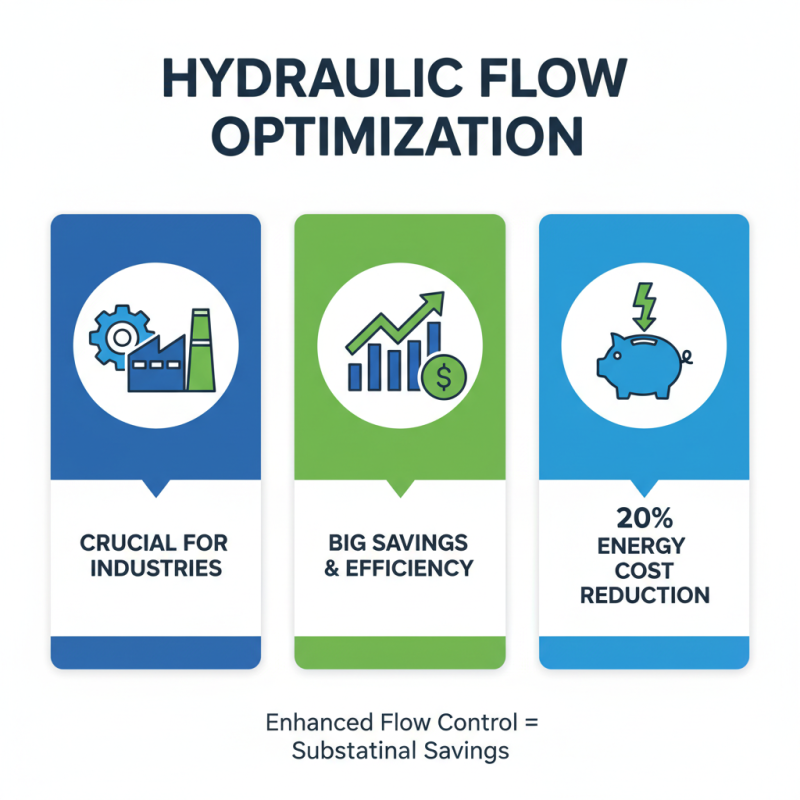

Optimizing hydraulic flow is crucial in various industries. Case studies reveal significant savings and efficiency improvements. For instance, a recent report indicated a 20% reduction in energy costs through enhanced flow control strategies. This reduction translates to substantial savings for companies operating machinery more efficiently.

In one study, an aerospace manufacturing facility optimized its hydraulic flow. Engineers redesigned the flow path. They minimized pressure drops, which improved overall system performance. The result? Enhanced productivity and reduced maintenance costs. These adjustments can lead to a 15% increase in operational reliability. However, challenges remain. Not all systems adapt well to modifications.

Another example comes from construction equipment. Many companies have examined hydraulic systems closely. They have seen variations in flow control methods. Some implementations yielded only marginal improvements. The key takeaway is a need for diligent planning and customized solutions. A one-size-fits-all approach often falls short. Monitoring and refining hydraulic flow is essential for long-term success in the sector.

Related Posts

-

Addressing Common Hydraulic Flow Control Challenges: Insights and Data from Industry Experts

-

7 Essential Tips for Choosing Hydraulic Flow Control Valves for Your Business

-

How to Select the Right Hydraulic Pressure Relief Valve for Your System Needs

-

How to Choose the Right Hydraulic Check Valve for Your System

-

Exploring the Future of Hydraulic Control Valves at the 2025 China Import and Export Fair

-

Unlocking Efficiency: How Hydraulic Directional Control Valves Boost Industrial Performance by 30%

skip to Main Content

skip to Main Content