What Are the Key Components of Hydraulics Products and Their Applications

In today's industrial landscape, hydraulics products play a pivotal role across various applications, from construction machinery to automotive systems. Understanding the key components of these products is essential for anyone involved in the design, maintenance, or operation of hydraulic systems. This blog aims to provide an insightful overview of the fundamental elements that constitute hydraulics products, including hydraulic pumps, cylinders, valves, and fluid connectors.

We will explore how each component functions and its significance in ensuring optimal performance and efficiency in hydraulic applications. Whether you are a seasoned engineer or a newcomer to the field, this guide will equip you with the knowledge needed to navigate the complexities of hydraulics and enhance your understanding of their practical implementations.

We will explore how each component functions and its significance in ensuring optimal performance and efficiency in hydraulic applications. Whether you are a seasoned engineer or a newcomer to the field, this guide will equip you with the knowledge needed to navigate the complexities of hydraulics and enhance your understanding of their practical implementations.

Key Elements of Hydraulic Systems and Their Functions

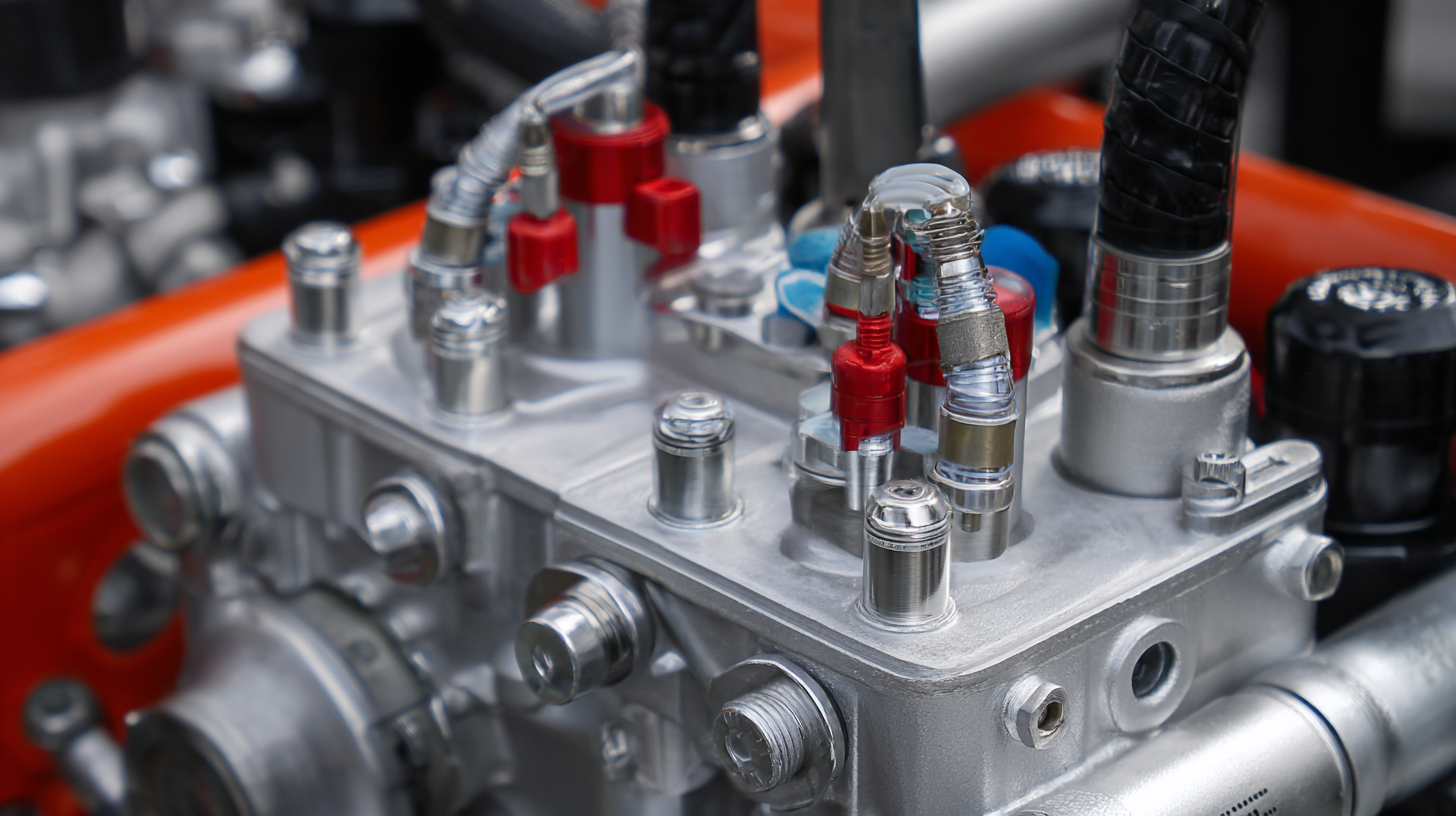

Hydraulic systems are essential in a wide range of industrial and automotive applications, utilizing pressurized fluid to transmit power. The core components that make up these systems include hydraulic pumps, actuators, valves, and reservoirs. Each of these elements plays a critical role in ensuring efficient operation. Hydraulic pumps are responsible for converting mechanical energy into hydraulic energy, pushing fluid through the system. They are typically the heart of the system, providing the necessary pressure to move the actuators.

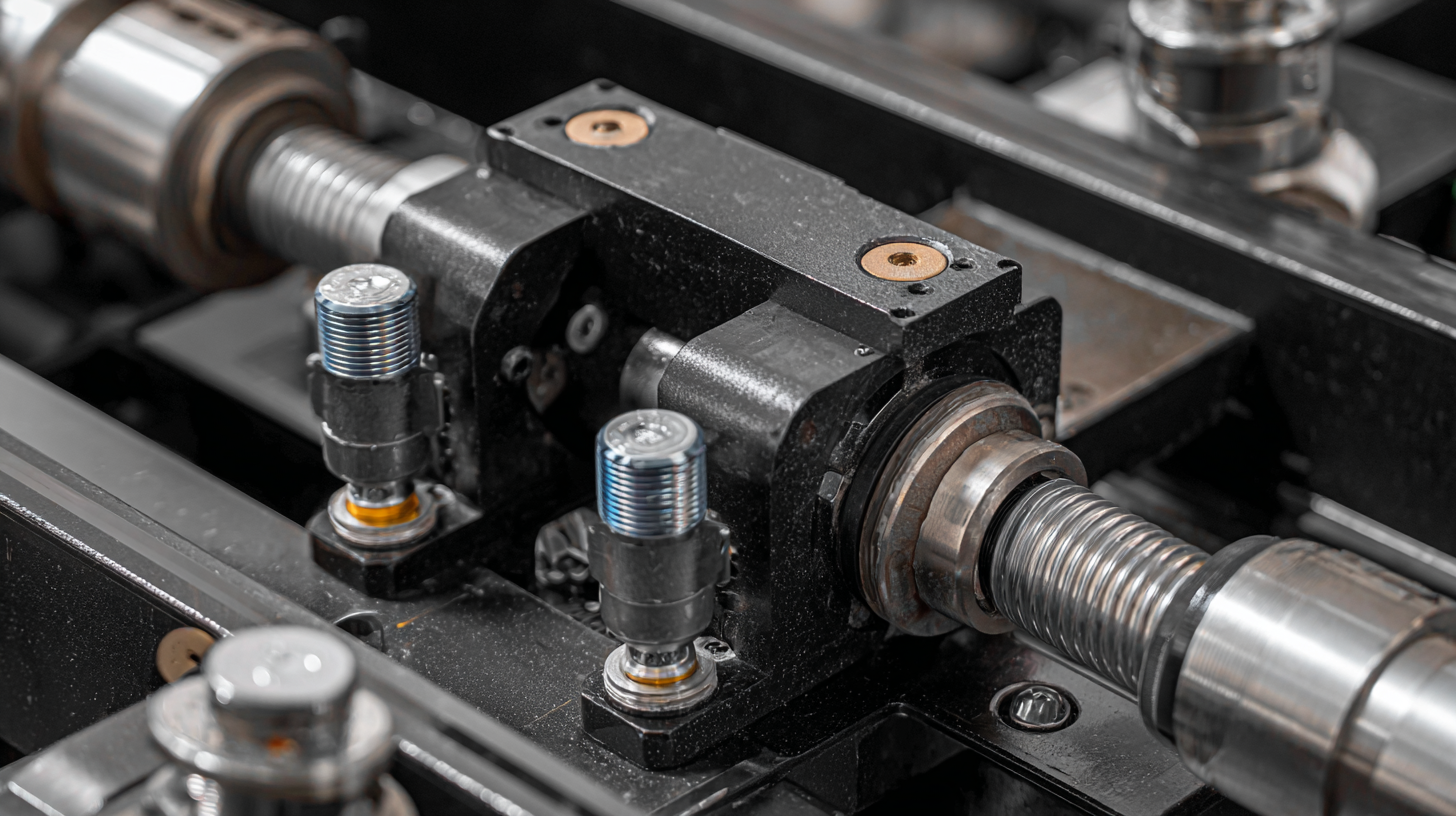

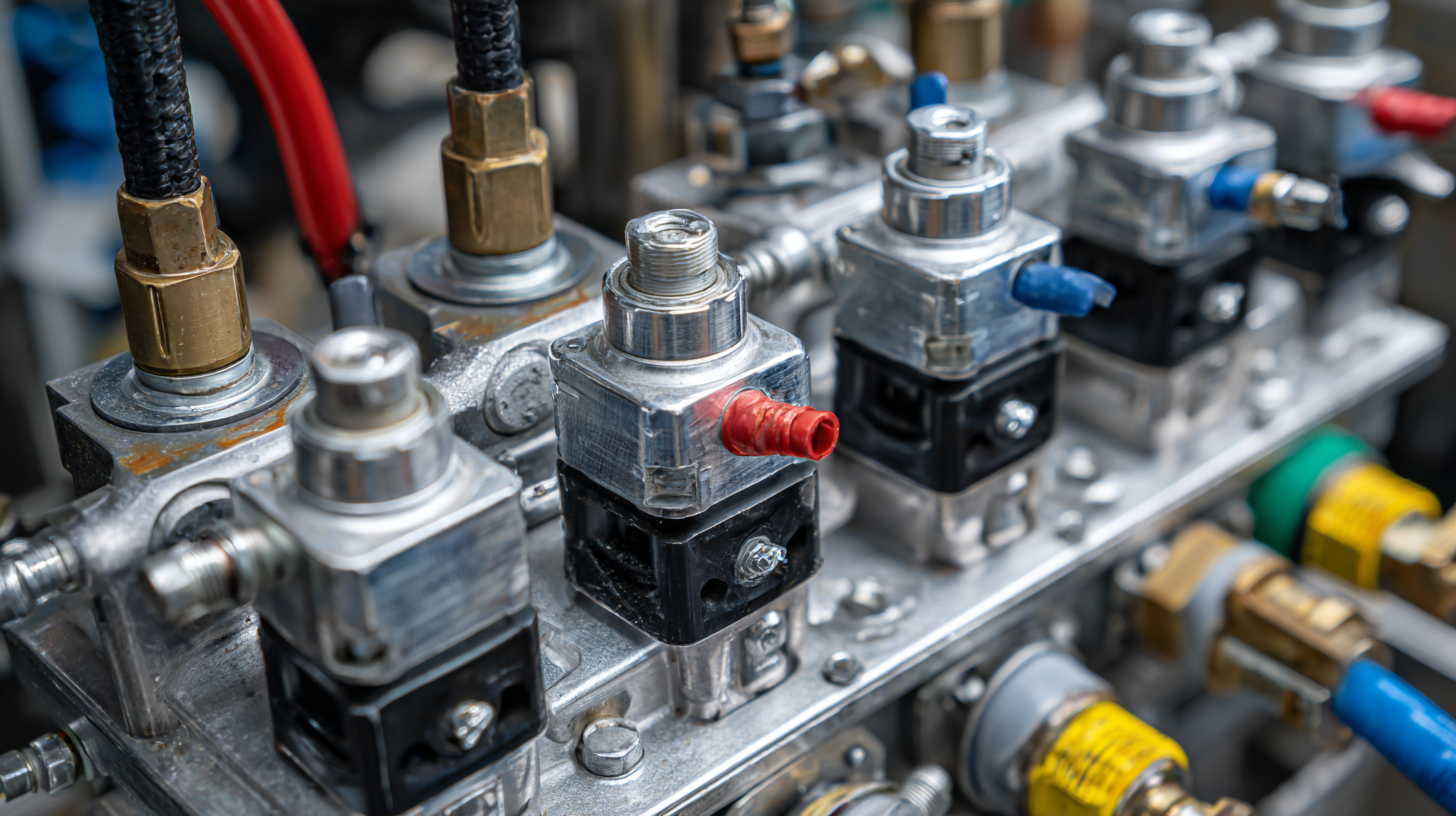

Actuators, which can be either hydraulic cylinders or motors, convert the energy from hydraulic pressure into mechanical work, enabling movement or the performance of tasks. Valves regulate the flow of fluid within the system, allowing for precise control over the actuators' operation. They direct, stop, or throttle the fluid, ensuring that the hydraulic power is used effectively and safely. Finally, reservoirs store hydraulic fluid, maintaining the system's operational integrity by compensating for leaks and providing adequate fluid supply during high-demand scenarios. Together, these key components underscore the functionality and versatility of hydraulic systems across diverse applications, from construction machinery to automotive systems.

Understanding the Role of Hydraulic Fluids in System Efficiency

Hydraulic systems are integral to a wide range of applications, from heavy machinery to automotive functions. At the heart of these systems lies hydraulic fluid, which plays a crucial role in their efficiency and effectiveness. Hydraulic fluids are responsible for transmitting power, lubricating moving parts, and assisting in heat dissipation, making their formulation and maintenance vital to the overall performance of hydraulic systems.

Understanding the types of hydraulic fluids, such as mineral oils and synthetic fluids, is essential for optimizing system efficiency. The right fluid selection can enhance the responsiveness and reliability of hydraulic operations. Additionally, properties such as viscosity, thermal stability, and compatibility with system components determine how well the fluid will perform under various operating conditions.

Regular monitoring of fluid quality and timely replacement can prevent equipment wear and maintain peak operational efficiency, reducing downtimes and increasing productivity across various applications.

Essential Components of Hydraulic Pumps and Their Applications

Hydraulic pumps are fundamental components in hydraulic systems, responsible for converting mechanical energy into hydraulic energy. The basic types of hydraulic pumps include gear, vane, and piston pumps, each serving distinct applications. Gear pumps are often used in high-flow scenarios, while vane pumps are favored for their efficiency in low-pressure systems. Piston pumps, on the other hand, excel in high-pressure environments and are commonly found in heavy machinery such as excavators and hydraulic presses.

When selecting a hydraulic pump, it's crucial to consider factors such as flow rate, pressure requirements, and the type of fluid being used. **Tip:** Always check the manufacturer's specifications to ensure compatibility with your hydraulic system. Additionally, regular maintenance can significantly extend the lifespan of your hydraulic pump. **Tip:** Implement a routine inspection schedule to catch potential issues early, ensuring efficient operation and preventing costly downtimes.

Furthermore, understanding the application of hydraulic pumps is essential for optimizing performance. They are employed in various sectors, from agriculture for powering tractors to manufacturing where they drive conveyor systems. **Tip:** Tailor your pump choice to the specific demands of your application to maximize efficiency and reliability.

Key Components of Hydraulic Pumps and Their Applications

The Importance of Hydraulic Actuators in Various Industries

Hydraulic actuators play a crucial role in numerous industries, acting as the driving force behind a plethora of machinery and systems. According to a report by MarketsandMarkets, the global hydraulic actuator market was valued at approximately $10 billion in 2021 and is projected to reach $13 billion by 2026, growing at a CAGR of 4.5%. This growth underscores the increasing reliance on hydraulic systems in sectors such as construction, automotive, aerospace, and manufacturing, where precision and power are paramount.

In the manufacturing industry, hydraulic actuators are essential for automation and precision control, enabling machines to perform complex movements with high efficiency. The AGV (Automated Guided Vehicle) segment, which frequently employs hydraulic actuators, is anticipated to see substantial growth, driven by advances in technology and the surging demand for automation. Additionally, the aerospace sector benefits from hydraulic actuators for their lightweight design and robust performance, enhancing aircraft safety and operational efficiency. The integration of these components not only improves productivity but also ensures improved safety standards, showcasing their irreplaceable nature in modern industrial applications.

What Are the Key Components of Hydraulics Products and Their Applications - The Importance of Hydraulic Actuators in Various Industries

| Component | Description | Applications | Importance |

|---|---|---|---|

| Hydraulic Actuator | Device that converts hydraulic energy into mechanical motion | Manufacturing, construction, automotive, aerospace | Enables precise control and high force generation |

| Hydraulic Pump | Transfers hydraulic fluid to create flow and pressure | Excavators, forklifts, agricultural machinery | Essential for the operation of hydraulic systems |

| Hydraulic Cylinder | Cylindrical chamber that produces linear motion | Cranes, mobile elevating work platforms, manufacturing lines | Provides high lifting capabilities with compact design |

| Hydraulic Hose | Flexible tube that carries hydraulic fluids | Various machinery, construction equipment, hydraulic systems | Transports fluid safely under pressure |

| Hydraulic Valve | Regulates the flow and pressure of hydraulic fluid | Industrial equipment, mobile machinery, aerospace systems | Critical for controlling the movement and speed of actuators |

Common Applications of Hydraulic Technology in Everyday Machinery

Hydraulic technology plays a crucial role in various everyday machinery, enhancing functionality and performance across multiple sectors. One of the most common applications is in construction equipment, such as excavators and bulldozers, where hydraulic systems are used to control powerful arms and attachments. This allows for precise movement and significant lifting capabilities, enabling heavy-duty tasks to be completed efficiently. Additionally, hydraulic power is essential for elevating platforms and forklifts, which rely on hydraulic pistons to lift loads safely and effectively.

Another key area where hydraulics shines is in automotive systems, particularly in braking and steering mechanisms. Hydraulic brakes provide the necessary force to stop vehicles quickly and reliably. Similarly, hydraulic steering systems improve handling and maneuverability, especially in larger vehicles like trucks and buses. Beyond transportation, hydraulic technology is also found in industrial machinery, such as presses and material handling equipment, where it enhances productivity by allowing machines to execute heavy tasks with ease. Overall, the applications of hydraulic technology are vast and integral to the functioning of numerous everyday machines, underscoring its value in modern industry.

Related Posts

-

Ultimate Checklist for Global Buyers in Fluid Power Procurement

-

7 Best Pressure Reducing Valves You Should Consider for Optimal Performance

-

10 Essential Flow Control Valves Every Industry Should Consider

-

Essential Checklist for Selecting the Right Hydraulic Check Valves for Your Applications

-

7 Essential Tips for Maximizing the Life of Your Continental Hydraulic Pump

-

Ultimate Flow Valves Maintenance Checklist for Optimal Performance and Longevity

skip to Main Content

skip to Main Content