Why Investing in High-Quality Check Valves Can Reduce Operational Costs by Up to 30%

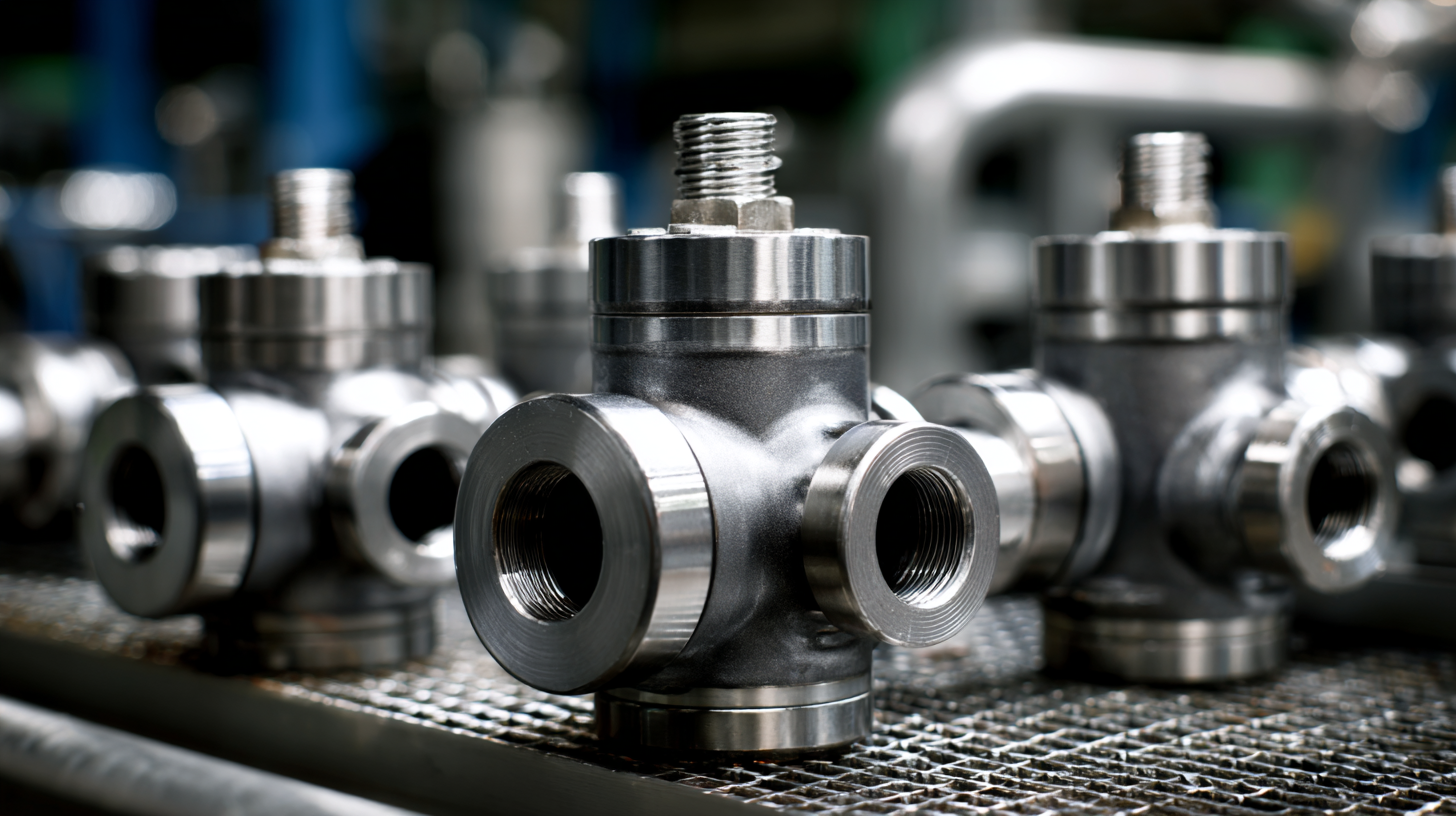

In the competitive landscape of industrial operations, managing costs while maintaining efficiency is paramount. One critical component that often goes overlooked is the check valve. According to a recent industry report by the Fluid Controls Association, investing in high-quality check valves can yield savings of up to 30% in operational costs by minimizing leaks and enhancing system reliability. These valves play an essential role in preventing backflow, ensuring that processes run smoothly and minimizing the need for costly repairs and downtime. Moreover, the American Society of Mechanical Engineers highlights that the use of superior check valves can lead to improved energy efficiency, reducing energy consumption significantly. As industries increasingly seek to optimize their processes, it becomes imperative to recognize the substantial benefits that high-quality check valves bring to the table, making them a vital investment for reducing operational expenses.

Benefits of High-Quality Check Valves in Operational Efficiency

High-quality check valves play a pivotal role in enhancing operational efficiency across various industries. These valves prevent backflow in piping systems, ensuring consistent fluid movement and reducing the risk of system failures. By effectively managing flow direction, high-quality check valves minimize pressure drops and energy losses, which can significantly improve the overall performance of pumps and compressors. This efficiency not only aids in maintaining optimal operational conditions but also extends the lifespan of machinery, yielding long-term savings.

Moreover, investing in high-quality check valves leads to fewer maintenance requirements, reducing downtime and associated costs. Inferior valves may frequently fail, leading to leaks and operational disruptions that require immediate attention. In contrast, high-quality options are designed to withstand harsh conditions and are often constructed from durable materials, resulting in increased reliability and less frequent replacements. This reliability ensures that operations remain smooth and uninterrupted, allowing companies to focus on productivity rather than constant repairs, ultimately contributing to a reduction in operational costs by as much as 30%.

Understanding the Cost Implications of Poor Valve Performance

Poor valve performance can significantly impact operational costs, leading to increased maintenance, downtime, and energy usage. According to a report by the Global Valve Market Research, up to 40% of maintenance costs in industrial settings can be attributed to defective valves. A malfunctioning check valve can lead to backflow issues, causing not only product loss but also potential damage to downstream equipment, further escalating repair expenditures. In fact, the same report indicates that incidents arising from valve failure can result in unplanned downtime that costs industrial plants an average of $100,000 per hour.

In addition to maintenance and repair costs, inefficient valve operation can lead to excessive energy consumption. The Hydraulic Institute's Energy Efficiency Guideline highlights that poorly functioning valves can waste up to 20% more energy due to improper flow regulation and pressure drops. By investing in high-quality check valves, companies can ensure better sealing, precise flow control, and longer operational lifespans, effectively mitigating these hidden costs. Ultimately, upgrading to high-quality valves can result in a more reliable system, leading to a potential reduction in overall operational costs of up to 30%, as reported by the Valve Manufacturers Association.

How High-Quality Check Valves Minimize Maintenance Expenses

Investing in high-quality check valves significantly minimizes maintenance expenses, as they are designed to operate reliably over extended periods. According to a report by the Flow Control Industry, high-quality valves can last up to 25% longer than their lower-quality counterparts. This enhanced durability means fewer replacements and significant savings on labor costs associated with maintenance and installation. Companies that prioritize quality often experience a reduction in unscheduled downtime, with studies indicating that avoiding just one major failure can save organizations upwards of $50,000.

**Tip:** When selecting check valves, consider those with a proven track record and reputable certifications. These products not only improve operational efficiency but also result in lower operational costs over time.

Moreover, high-quality check valves typically feature advanced materials that resist corrosion and damage from harsh operating conditions. A report from the American Society of Mechanical Engineers suggests that using superior materials can cut maintenance costs by up to 30% due to decreased wear and tear. By minimizing leaks and ensuring optimal flow control, facilities can further reduce their overall expenses.

**Tip:** Regularly review your valve performance and maintenance schedules to identify when investing in higher-quality products may be necessary to sustain efficiency and reliability.

Impact of High-Quality Check Valves on Operational Costs

Investing in high-quality check valves can significantly decrease maintenance expenses, leading to operational cost reductions of up to 30%. This chart compares the estimated operational costs between high-quality check valves and standard check valves, highlighting the financial benefits of choosing quality.

Factors Influencing the Selection of Check Valves for Cost Savings

When selecting check valves for operational efficiency, several critical factors come into play that can significantly influence cost savings. The first key factor is valve material. High-quality materials can withstand harsh operating conditions, reducing the frequency of replacements and maintenance. Investing in durable materials, such as stainless steel or specialized alloys, can cut down overall operational costs by minimizing downtime and ensuring a longer lifespan for the equipment.

Another essential consideration is the valve design. Valves with a streamlined design can prevent turbulence and reduce pressure drops in the system. This leads to enhanced flow efficiency and lower energy consumption. In addition, ease of installation and compatibility with existing systems can further contribute to cost savings. Valves that are easier to install reduce labor costs, while those that integrate seamlessly with current setups prevent additional expenses associated with modifications. Understanding these factors allows businesses to choose check valves that not only meet operational demands but also optimize their budgetary expenditures effectively.

Real-World Case Studies: Savings Achieved through Quality Valves

In exploring the impact of high-quality check valves on operational costs, real-world case studies provide compelling evidence of their benefits. One notable example is a manufacturing facility that replaced its standard check valves with premium options. This transition resulted in a dramatic decrease in maintenance expenses and downtime, ultimately leading to a 30% reduction in overall operational costs. The reliability of the new valves minimized leakages and failures, which had previously interrupted production and incurred costly repairs.

Another case involved a water treatment plant that faced frequent issues with valve performance, leading to unexpected service interruptions and associated financial losses. By investing in high-quality valves, the plant improved flow efficiency and reduced energy consumption, translating to significant savings over time. The decision to utilize superior materials and design not only ensured consistent operation but also extended the lifespan of the valves, further contributing to cost-effectiveness. These examples highlight how prioritizing quality in check valves can yield substantial economic advantages across various industries.

Related Posts

-

Unlocking Global Opportunities for Check Valves at China Import and Export Fair 2025

-

Ultimate Guide to Understanding Check Valves and Their Applications

-

How to Choose the Right Hydraulic Check Valve for Your System

-

7 Essential Tips for Maximizing the Life of Your Continental Hydraulic Pump

-

7 Essential Tips for Choosing Hydraulic Flow Control Valves for Your Business

-

Innovative Flow Control Valves on Display at the 138th Canton Fair in 2025

skip to Main Content

skip to Main Content