Understanding the Importance of Pressure Control Valves in Modern Industrial Applications

In modern industrial applications, the significance of pressure control valves cannot be overstated. These critical components are essential for maintaining safe and efficient system operations across various sectors, including oil and gas, chemical manufacturing, and water management. According to a report by MarketsandMarkets, the global pressure control valve market is projected to grow from USD 7.2 billion in 2020 to USD 10.2 billion by 2025, reflecting an annual growth rate of 7.5%. This growth is driven by the increasing demand for automation and process optimization in industries where pressure regulation is paramount for operational safety and cost efficiency.

With their ability to regulate fluid flow and maintain desired pressure levels, pressure control valves help prevent catastrophic failures and downtime, thereby underscoring their importance in the contemporary industrial landscape.

The Role of Pressure Control Valves in Maintaining System Stability

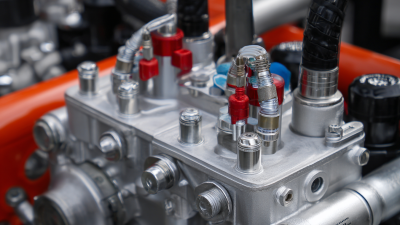

Pressure control valves (PCVs) play a critical role in maintaining system stability within various industrial applications. By regulating the pressure within pipelines and equipment, these valves ensure that processes operate within specified limits, preventing potential damage from overpressure conditions. Uncontrolled pressure fluctuations can lead to system failures, leaks, or even catastrophic accidents. Thus, the implementation of reliable PCVs is essential for safeguarding both equipment and personnel.

Moreover, pressure control valves contribute to the efficiency and performance of industrial systems. By maintaining optimal pressure levels, they help to enhance energy efficiency and resource utilization. This stability not only supports continuous operations but also reduces the likelihood of downtime due to equipment malfunctions. As industries evolve and adopt more complex automation and control systems, the importance of PCVs in maintaining operational integrity cannot be overstated. Their integration into modern industrial applications ensures a safer and more efficient working environment, reflecting the growing reliance on sophisticated pressure management solutions.

Understanding the Importance of Pressure Control Valves in Modern Industrial Applications - The Role of Pressure Control Valves in Maintaining System Stability

| Application Area | Function | Pressure Range (psi) | Common Materials | Key Benefits |

|---|---|---|---|---|

| Oil and Gas | Regulate pressure to safe levels | 50 - 5000 | Stainless Steel, Brass | Prevents leaks, enhances safety |

| Chemical Processing | Control pressure in reaction vessels | 100 - 3000 | Alloy Steel, PVC | Ensures consistent reactions, minimizes risks |

| Food and Beverage | Maintain pressure for food processing | 30 - 150 | Stainless Steel, Food-grade Plastics | Safety, compliance with standards |

| Water Treatment | Control pressure in filtration systems | 10 - 200 | Copper, Plastic | Enhances system efficiency, reduces downtime |

Key Benefits of Implementing Pressure Control Valves in Industries

In modern industrial applications, the implementation of pressure control valves is crucial for efficient operation. These valves help regulate the pressure within systems, ensuring safety and optimal performance. By maintaining a consistent pressure level, industries can prevent equipment damage, reduce downtime, and enhance productivity. Additionally, pressure control valves contribute to energy savings by minimizing unnecessary pressure fluctuations, which can result in wasted energy and increased operational costs.

**Tips:** When selecting pressure control valves, consider the specific requirements of your system, including flow rate and pressure range. Regular maintenance checks can also significantly extend the lifespan of these components. Implementing a robust monitoring system can further streamline operations and facilitate timely adjustments, ensuring that pressure levels remain stable and within the desired parameters.

Another key benefit of using pressure control valves is their role in improving process control and product quality. By allowing for precise pressure adjustments, these valves help maintain ideal conditions for various industrial processes, whether in manufacturing or chemical production. This not only enhances the quality of the final product but also minimizes the risk of contamination or product failure.

**Tips:** Invest in high-quality valves that are compatible with your system's materials to prevent corrosion and ensure reliability. Training personnel on the importance of pressure management can foster a culture of safety and efficiency within the organization.

Best Practices for Selecting the Right Pressure Control Valve

When selecting the right pressure control valve for industrial applications, it is imperative to consider several key factors to ensure optimal performance and safety.

First, understanding the specific requirements of the system is crucial. This includes evaluating the pressure range, flow capacity, and the kind of media being controlled, such as liquids or gases. Knowing these parameters will help narrow down the options and select a valve that can handle the operating conditions effectively.

Another important aspect is the material composition of the valve. Different materials offer varying levels of resistance to corrosion, temperature, and pressure fluctuations. For applications involving corrosive substances or extreme temperatures, selecting a valve made from compatible materials is essential to prevent failure and ensure longevity. Additionally, consulting the manufacturer’s specifications and maintenance guidelines can provide insights into the valve's reliability and service life, further aiding in the selection process. Engaging with industry experts or utilizing simulation software may also enhance the decision-making process, ensuring the chosen pressure control valve meets all operational demands.

Common Challenges in Pressure Regulation and How to Overcome Them

Pressure control valves play a crucial role in modern industrial applications, particularly in ensuring efficient and safe operations across various sectors. However, several common challenges in pressure regulation persist, making it essential for industries to address these issues effectively. For instance, outdated pressure transmitters pose a significant obstacle, especially in aging infrastructures like nuclear power plants. According to industry reports, the failure rate of pressure transmitters can increase significantly as they age, leading to unsafe operating conditions and costly downtimes.

Moreover, the integration of advanced technologies presents another challenge. As industries strive to adopt IoT and smarter systems for better data utilization, many facilities encounter difficulties in retrofitting existing systems. A recent analysis highlights that nearly 60% of industrial plants face obstacles from legacy equipment that cannot be easily integrated with modern data-driven solutions. To overcome these challenges, regular maintenance and proactive upgrades of pressure control systems are imperative. Additionally, investing in technology that allows for seamless communication between old and new systems can enhance regulatory compliance and operational efficiency, ultimately paving the way for sustained growth in a competitive landscape.

Innovative Technologies Enhancing Pressure Control Valve Efficiency

In modern industrial applications, pressure control valves (PCVs) play a crucial role in ensuring the safe and efficient operation of various systems. Recent advancements in innovative technologies have significantly enhanced the efficiency of these valves. According to a report by Research and Markets, the global market for pressure control valves is expected to reach $9.3 billion by 2025, driven by the demand for improved process automation and energy efficiency.

Innovations such as smart sensors and advanced materials are transforming the way PCVs operate. Smart sensors can provide real-time data on system conditions, allowing for dynamic adjustments to pressure settings. This capability not only enhances system performance but also reduces energy consumption by up to 20%, according to a study published in the Journal of Industrial Technology. Furthermore, the introduction of corrosion-resistant materials has extended the lifespan of pressure control valves, minimizing maintenance costs and downtime.

As industries continuously strive to optimize their operations, the integration of innovative technologies in pressure control valves represents a significant step forward. Enhanced efficiency and reliability not only lead to better performance but also contribute to compliance with increasingly stringent environmental regulations. As noted in a recent survey by the International Society of Automation, 75% of industry leaders consider the upgrading of traditional pressure control systems to smarter technologies as a priority for the next five years.

Understanding the Importance of Pressure Control Valves in Modern Industrial Applications

This chart illustrates the comparative performance metrics of pressure control valves before and after the implementation of innovative technologies. Enhanced efficiencies, reduced costs, decreased maintenance frequency, and improved response times highlight the critical advancements in this area.

Related Posts

-

7 Best Pressure Reducing Valves You Should Consider for Optimal Performance

-

What Are the Key Components of Hydraulics Products and Their Applications

-

Ultimate Checklist for Global Buyers in Fluid Power Procurement

-

Ultimate Flow Valves Maintenance Checklist for Optimal Performance and Longevity

-

Unlocking Efficiency: How Hydraulic Directional Control Valves Boost Industrial Performance by 30%

-

Addressing Common Hydraulic Flow Control Challenges: Insights and Data from Industry Experts

skip to Main Content

skip to Main Content