Top 10 Hydraulic Pressure Relief Valves for Optimal Equipment Performance

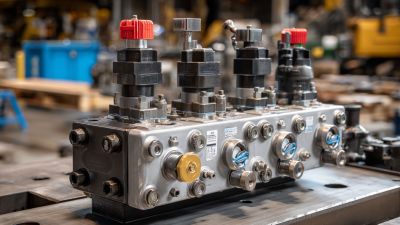

In the world of hydraulic systems, the importance of hydraulic pressure relief valves cannot be overstated. These crucial components play a pivotal role in ensuring the safe and efficient operation of various types of equipment by preventing excessive pressure buildup, which can lead to catastrophic failures. As industries increasingly rely on hydraulic machinery for their operations, understanding the various options available for hydraulic pressure relief valves becomes essential for optimizing equipment performance.

This article aims to present a comprehensive overview of the top 10 hydraulic pressure relief valves, each selected for their effectiveness, reliability, and suitability for a wide range of applications. By examining their features and benefits, we will highlight how the right hydraulic pressure relief valve can enhance both safety and productivity in hydraulic systems. Whether you are an engineer looking to upgrade existing systems or a technician tasked with maintenance, this guide will serve as a valuable resource in navigating the options available in the market today.

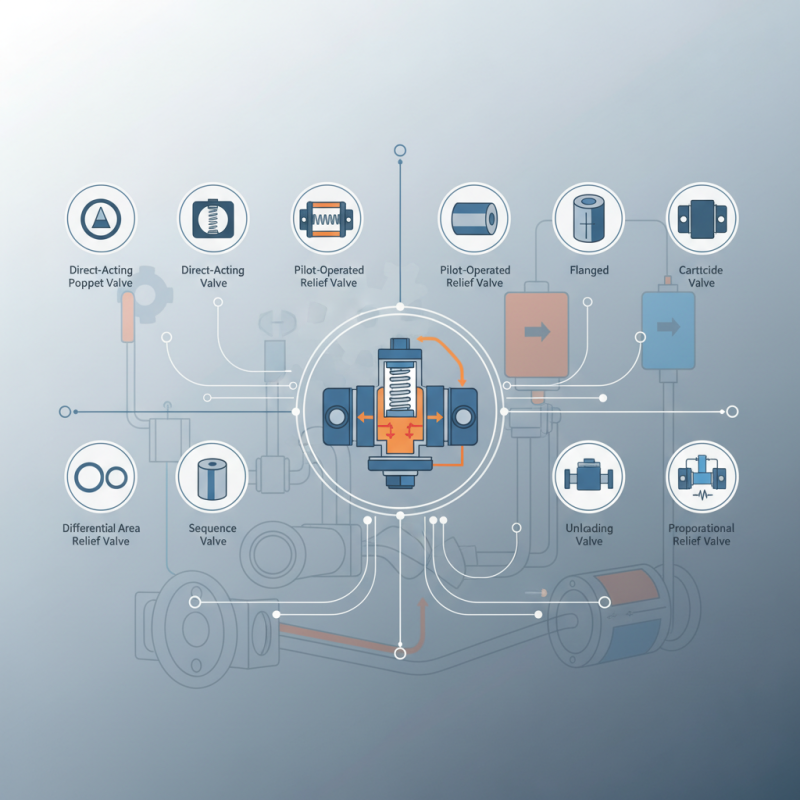

Understanding Hydraulic Pressure Relief Valves and Their Functionality

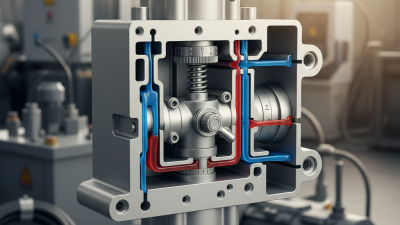

Hydraulic pressure relief valves are crucial components in hydraulic systems, ensuring optimal performance and safety. These valves are designed to regulate the pressure within hydraulic circuits by venting excess pressure to prevent system overload. When the hydraulic pressure exceeds a pre-set limit, the relief valve activates, redirecting the flow back to the reservoir. This function not only protects equipment from damage but also minimizes the risk of catastrophic failures, thereby extending the system's lifespan.

Understanding the functionality of hydraulic pressure relief valves is essential for maintaining effective hydraulic operations. They operate based on a simple principle: balancing the force exerted by the hydraulic fluid against a spring-loaded mechanism. When the pressure in the system rises beyond the threshold, the valve opens, allowing fluid to escape, which quickly reduces pressure levels. This mechanism is vital for maintaining stable operation during peak loads and sudden pressure spikes, enabling machinery to function efficiently while safeguarding against risks associated with hydraulic failures. Proper selection and maintenance of these valves are key to achieving optimum performance in any hydraulic application.

Top 10 Hydraulic Pressure Relief Valves Performance Comparison

This chart displays the performance metrics of the top 10 hydraulic pressure relief valves based on their maximum pressure capacity (in bar) and flow rate (in L/min). The data is segmented by valve type to illustrate the optimal performance characteristics for various equipment applications.

Key Features to Consider When Choosing the Best Relief Valves

When choosing the best hydraulic pressure relief valves for optimal equipment performance, several key features should be carefully considered. First and foremost is the valve size, which must match the specifications of the application to ensure it can handle the required flow rates and pressures. An appropriately sized valve will maintain system stability and prevent undesirable pressure spikes, thus protecting the hydraulic components from potential damage.

Another critical aspect is the set pressure range of the valve, which determines when the valve will open to relieve excess pressure. It's essential to select a valve that offers a set pressure range suitable for the specific requirements of your equipment. Additionally, consider the ease of adjustment; a valve that can be easily fine-tuned allows for more precise control of the hydraulic system's performance.

Lastly, the material and construction of the valve are vital in ensuring durability and reliability. Materials should be chosen based on the working environment and fluid type to prevent corrosion and ensure longevity. Moreover, factors such as response time and flow characteristics should be evaluated to ensure the valve operates efficiently under various conditions. By focusing on these essential features, you can select a hydraulic pressure relief valve that enhances performance and reliability in your equipment.

Top 10 Hydraulic Pressure Relief Valves for Different Applications

Hydraulic pressure relief valves play a crucial role in ensuring the safety and efficiency of various hydraulic systems across different applications. These valves are designed to limit the maximum pressure within hydraulic circuits, thereby protecting equipment from potential damage due to overpressure situations. According to the International Organization for Standardization (ISO) standards, proper selection and sizing of hydraulic pressure relief valves can significantly enhance system reliability, with optimal sizing reducing energy consumption by up to 15%. Each application, whether in mobile machinery, industrial equipment, or fluid power systems, has unique demands that determine the specific type of relief valve required.

For instance, in the construction industry, hydraulic pressure relief valves are essential for loaders and excavators, where fluctuations in load can lead to rapid pressure changes. Reports from the National Fluid Power Association (NFPA) indicate that using properly calibrated relief valves in mobile machinery can extend component life by as much as 25%. Meanwhile, in industrial settings, where strict safety regulations must be adhered to, relief valves are critical in maintaining stable pressure levels in hydraulic presses and assemblies, ensuring operational safety and compliance with regulatory standards. Given the various applications and their unique requirements, selecting the right relief valve is key to optimizing equipment performance and ensuring safety across hydraulic systems.

Top 10 Hydraulic Pressure Relief Valves for Optimal Equipment Performance

| Rank | Model | Pressure Range (psi) | Max Flow Rate (GPM) | Material | Applications |

|---|---|---|---|---|---|

| 1 | Model A | 1500 | 30 | Aluminum | Construction |

| 2 | Model B | 2000 | 45 | Steel | Agriculture |

| 3 | Model C | 1000 | 25 | Brass | Manufacturing |

| 4 | Model D | 2500 | 60 | Stainless Steel | Mining |

| 5 | Model E | 3000 | 50 | Copper | Oil & Gas |

| 6 | Model F | 1200 | 35 | Aluminum | Food Processing |

| 7 | Model G | 1800 | 40 | Steel | Automotive |

| 8 | Model H | 2200 | 55 | Brass | Marine |

| 9 | Model I | 2900 | 65 | Stainless Steel | Power Generation |

| 10 | Model J | 1600 | 50 | Copper | Plastic Manufacturing |

Comparative Analysis of Performance Metrics for Selected Valves

When evaluating hydraulic pressure relief valves, performance metrics such as cracking pressure, flow capacity, and response time are critical to ensuring optimal equipment performance. A comparative analysis of these metrics can help users identify the most suitable valve for specific applications. For instance, valves with lower cracking pressures may offer quicker relief, making them ideal for sensitive hydraulic systems. In contrast, valves designed with higher flow capacities can manage larger surges, which is essential for heavy machinery operating under high pressure.

Tips: Always consider the specific requirements of your hydraulic system before selecting a valve. It’s advisable to analyze not just the specifications but also the operating environment in which the valve will function. Perform regular maintenance and inspections to ensure the valves are functioning at their best, as even small deviations in performance can lead to system inefficiencies.

Furthermore, when comparing different valves, pay close attention to their construction materials and design features. Materials that resist corrosion and wear can significantly extend the lifespan of a valve. Additionally, valves with innovative designs might offer better sealing and leak prevention, further enhancing overall hydraulic system reliability. Investing time in understanding these factors can lead to improved performance and prolonged equipment life.

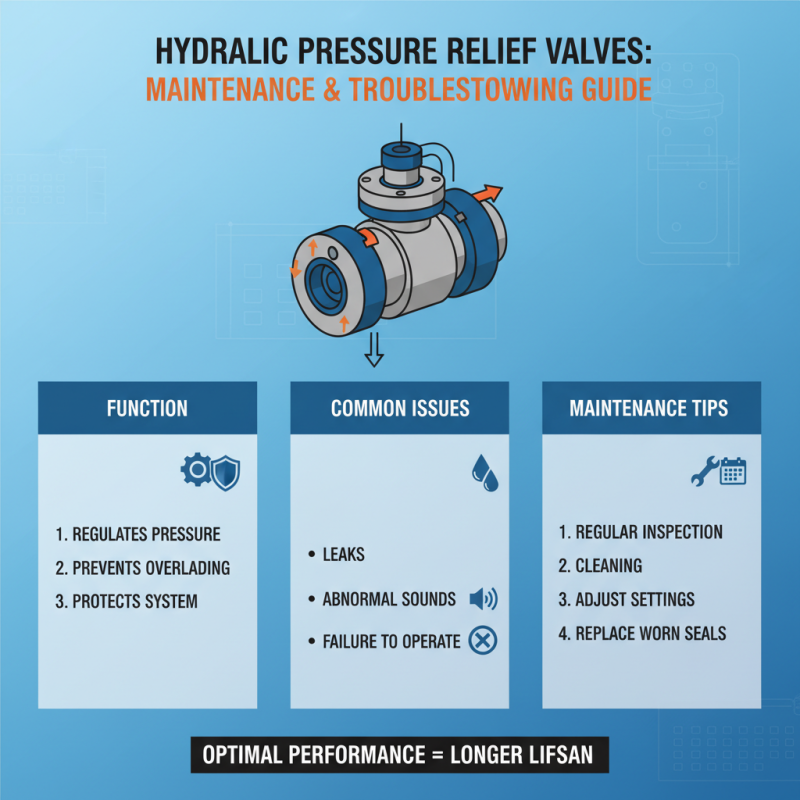

Maintaining and Troubleshooting Hydraulic Pressure Relief Valves

Hydraulic pressure relief valves are critical components in many industrial applications, regulating the pressure within hydraulic systems to prevent overloading and potential damage. To maintain optimal performance, it is essential to regularly inspect and troubleshoot these valves. Common issues that can arise include leaks, abnormal sounds, or failure to open or close as intended. Regular maintenance such as cleaning, adjusting settings, and replacing worn seals can significantly extend the lifespan of these valves and ensure efficient operation.

When troubleshooting hydraulic pressure relief valves, it is important to follow a systematic approach. Begin by checking for visible leaks and any signs of corrosion around the valve body. Next, assess the valve’s response to changes in pressure; it should open and close smoothly without sticking. If the valve fails to activate at the predetermined pressure, calibration may be necessary. Additionally, examining the hydraulic fluid's condition and cleanliness is vital, as contaminants can lead to valve malfunction. By monitoring these key aspects, operators can prevent major breakdowns and maintain the seamless functionality of their hydraulic systems.

Related Posts

-

Exploring the Future of Hydraulic Control Valves at the 2025 China Import and Export Fair

-

How to Choose the Right Hydraulic Valves for Your Industrial Needs

-

Unlocking Efficiency: How Hydraulic Directional Control Valves Boost Industrial Performance by 30%

-

Understanding the Essential Role of Continental Hydraulic Valves in Modern Industry

-

Why Hydraulic Flow Control Valves Are Essential for Optimal Machinery Performance

-

7 Essential Tips for Choosing Hydraulic Flow Control Valves for Your Business

skip to Main Content

skip to Main Content