How to Understand Hydraulic Flow Control in Simple Steps?

Understanding hydraulic flow control is essential for anyone involved in fluid dynamics or machinery operations. This concept plays a vital role in various industries, including manufacturing and construction. Hydraulic systems use fluid mechanics to transmit power, enabling smooth operation of heavy machinery.

Hydraulic flow control refers to the regulation of fluid flow within a hydraulic system. It governs how much fluid moves through pipes and valves. Improper management of hydraulic flow can lead to inefficiencies and equipment failure. For instance, a needle valve controls flow but can become restricted over time. This emphasizes the importance of regular maintenance and monitoring.

When learning about hydraulic flow control, visualizing the components can help. Think of it like directing water through a hose. If the hose is kinked or blocked, the flow diminishes. Understanding these dynamics is crucial for optimizing system performance. Yet, beginners often overlook small details, leading to major mistakes. It's a journey filled with learning, and every step counts.

Understanding the Basics of Hydraulic Flow Control

Understanding hydraulic flow control is essential for anyone working with fluid systems. Hydraulic flow control refers to managing the flow of hydraulic fluids through various components. It helps ensure that machines operate smoothly and efficiently. Simple devices, like valves and pumps, control this flow. However, the interplay between pressure and flow rate can sometimes be confusing.

In hydraulic systems, flow control can be visualized through the use of throttling valves. These valves restrict fluid flow, altering pressure and velocity. This change impacts the system's performance. If a valve is partially closed, it can reduce flow but increase pressure upstream. Such dynamics can create unexpected challenges. It's important to experiment and monitor the system to understand these changes deeply.

One common mistake is assuming that more flow equals better performance. It's crucial to find the right balance. Overly high flow can lead to inefficiencies and equipment wear. Each component must work together in harmony. Understanding these basics makes the learning curve less steep. A hands-on approach, paired with observation, often yields the best results.

How to Understand Hydraulic Flow Control in Simple Steps?

| Component | Function | Flow Control Method | Common Applications |

|---|---|---|---|

| Hydraulic Pump | Generates hydraulic flow | Variable Speed Control | Excavators, Cranes |

| Flow Control Valve | Regulates flow rate | Throttle Control | Injection Molding Machines |

| Pressure Relief Valve | Prevents overpressure | Spring-loaded Control | Hydraulic Systems |

| Flow Meter | Measures flow rate | Electronic or Mechanical | Manufacturing Processes |

| Actuator | Converts hydraulic energy into mechanical movement | Proportional Control | Robotics, Automation |

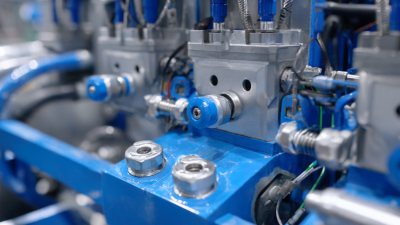

Key Components of Hydraulic Flow Control Systems

Hydraulic flow control systems rely on several key components to regulate fluid movement in machinery. The main parts include valves, pumps, reservoirs, and actuators. Each of these components plays a vital role in ensuring efficient system performance. For example, valves control fluid direction and pressure. A study from the International Fluid Power Society highlighted that poorly calibrated valves can lead to energy losses of up to 15%.

Pumps are essential for moving the hydraulic fluid. They need to match the system's requirements for pressure and flow rate. Selecting the right pump is critical. Incorrect choices can result in suboptimal operation. This mismatch could even cause system failure. Reservoirs store hydraulic fluid, ensuring a consistent supply. An inadequate reservoir can lead to cavitation, damaging pumps and valves.

**Tips:** Regular maintenance can extend component life. Check for leaks and ensure proper fluid levels. Monitor the flow rate; fluctuations may indicate issues. Remember, even small changes can have significant effects. Evaluate your system routinely. Your attention to detail can prevent costly repairs.

Understanding Hydraulic Flow Control - Key Components Overview

Principles of Fluid Dynamics in Hydraulic Systems

Hydraulic systems rely heavily on fluid dynamics principles. Understanding these principles is essential for effective hydraulic flow control. For instance, Bernoulli's principle explains how fluid velocity and pressure interact. In a hydraulic system, an increase in fluid velocity leads to a drop in pressure. This concept is critical for optimizing system performance.

Consider real-world applications. According to industry reports, hydraulic systems in construction contribute to 30% of the equipment's efficiency. However, improper flow control may lead to energy losses. A flow rate that is too high can create turbulence. This turbulence reduces efficiency and increases wear on components.

Systems must be regularly evaluated. Flow control valves, for example, play a vital role. Many users overlook their maintenance. In fact, neglected valves can disrupt flow dynamics, leading to costly downtime. Keeping track of flow rates and pressures is necessary. It is often the small details that reveal significant inefficiencies in a hydraulic system.

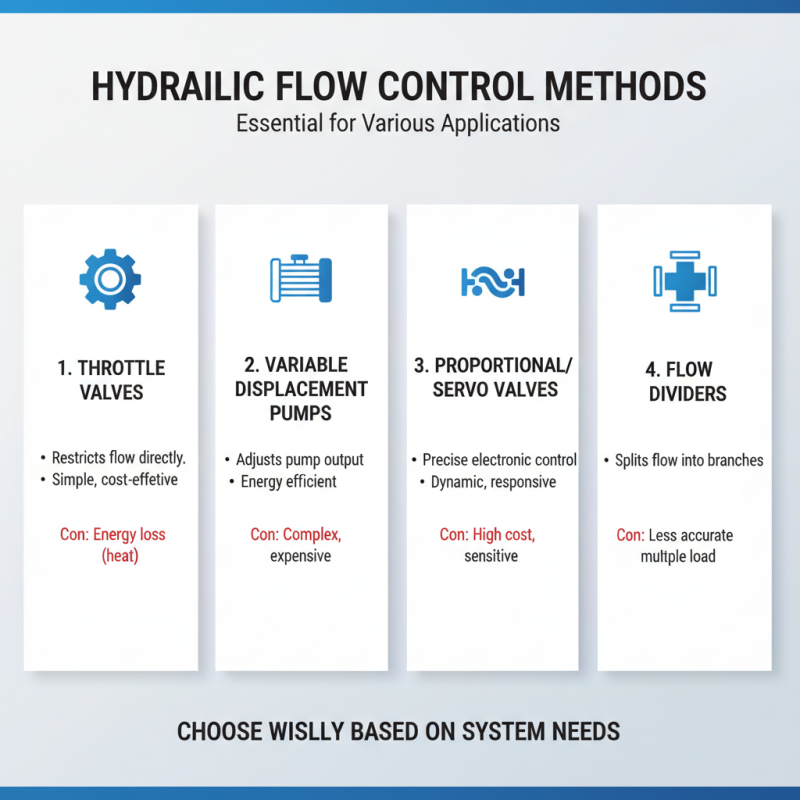

Common Methods for Controlling Hydraulic Flow

Controlling hydraulic flow is essential in various applications. There are several common methods to achieve this. Each method has its pros and cons. Understanding these can help you make better choices in hydraulic systems.

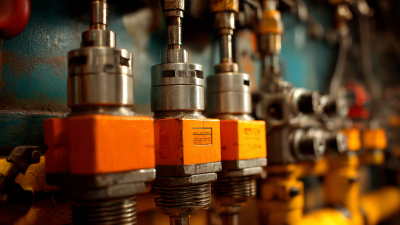

One method is the use of flow control valves. These valves regulate the flow rate in hydraulic systems. They can be adjusted easily. A downside is that they might wear out over time. Regular maintenance is crucial to avoid failures. Another method is the variable speed drive. This adjusts the speed of the pump. While this can save energy, it can also increase complexity in the system. Not all systems can handle this change.

Additionally, orifice plates can regulate flow by creating a restriction. They are simple to install but can lead to pressure drops. This could impact overall efficiency. It's essential to evaluate the specific needs of your system. Every method has trade-offs that require careful thought and analysis.

Practical Applications of Hydraulic Flow Control in Industry

Hydraulic flow control is crucial in various industries. It allows for efficient operation of machinery. This encompasses construction, manufacturing, and transportation. Understanding flow control can enhance productivity. However, many struggle with its complexities.

One common application of hydraulic flow control is in excavators. They use hydraulic systems to lift and move heavy materials. A well-tuned hydraulic flow can improve speed and precision. Yet, if not properly maintained, hydraulic systems can fail. Regular checks are necessary to ensure optimal performance.

Tip: Monitor your hydraulic fluid levels regularly. Low fluid can lead to poor performance. Also, look out for leaks. Small leaks can indicate bigger problems.

Another example is in elevators. They rely on hydraulic systems for smooth operation. Incorrect flow settings may lead to jerky movements. This can create uncomfortable rides. Regular calibration of flow control is essential.

Tip: Always follow the manufacturer's guidelines for adjustments. Don’t hesitate to seek professional help. Incorrect adjustments can worsen issues unnecessarily.

Related Posts

-

How to Optimize Hydraulic Flow Control for Maximum Efficiency

-

7 Essential Tips for Effective Hydraulic Flow Control in Your System

-

10 Essential Tips for Mastering Hydraulic Flow Control Techniques

-

Ultimate Guide to Mastering Hydraulic Flow Control Techniques for Optimal Performance

-

Addressing Common Hydraulic Flow Control Challenges: Insights and Data from Industry Experts

-

How to Choose the Right Hydraulic Valves for Your Industrial Needs

skip to Main Content

skip to Main Content