Unlocking Efficiency: How Hydraulic Directional Control Valves Boost Industrial Performance by 30%

In today's fast-paced industrial landscape, maximizing operational efficiency is paramount for sustained growth and competitiveness. Hydraulic directional control valves play a crucial role in achieving this by enhancing the performance of hydraulic systems across various applications. According to a recent industry report by MarketsandMarkets, the global hydraulic valves market is projected to reach USD 27.7 billion by 2025, driven by the increasing demand for automation and efficiency in manufacturing processes. Additionally, a study from the International Journal of Engineering Research highlights that effective use of hydraulic directional control valves can lead to a productivity increase of up to 30%. By optimizing fluid flow and pressure in hydraulic circuits, these valves not only streamline operations but also minimize energy consumption, contributing to more sustainable industrial practices. As industries continue to embrace digital transformation, integrating advanced hydraulic solutions becomes essential for staying ahead in competition.

Understanding Hydraulic Directional Control Valves and Their Functionality

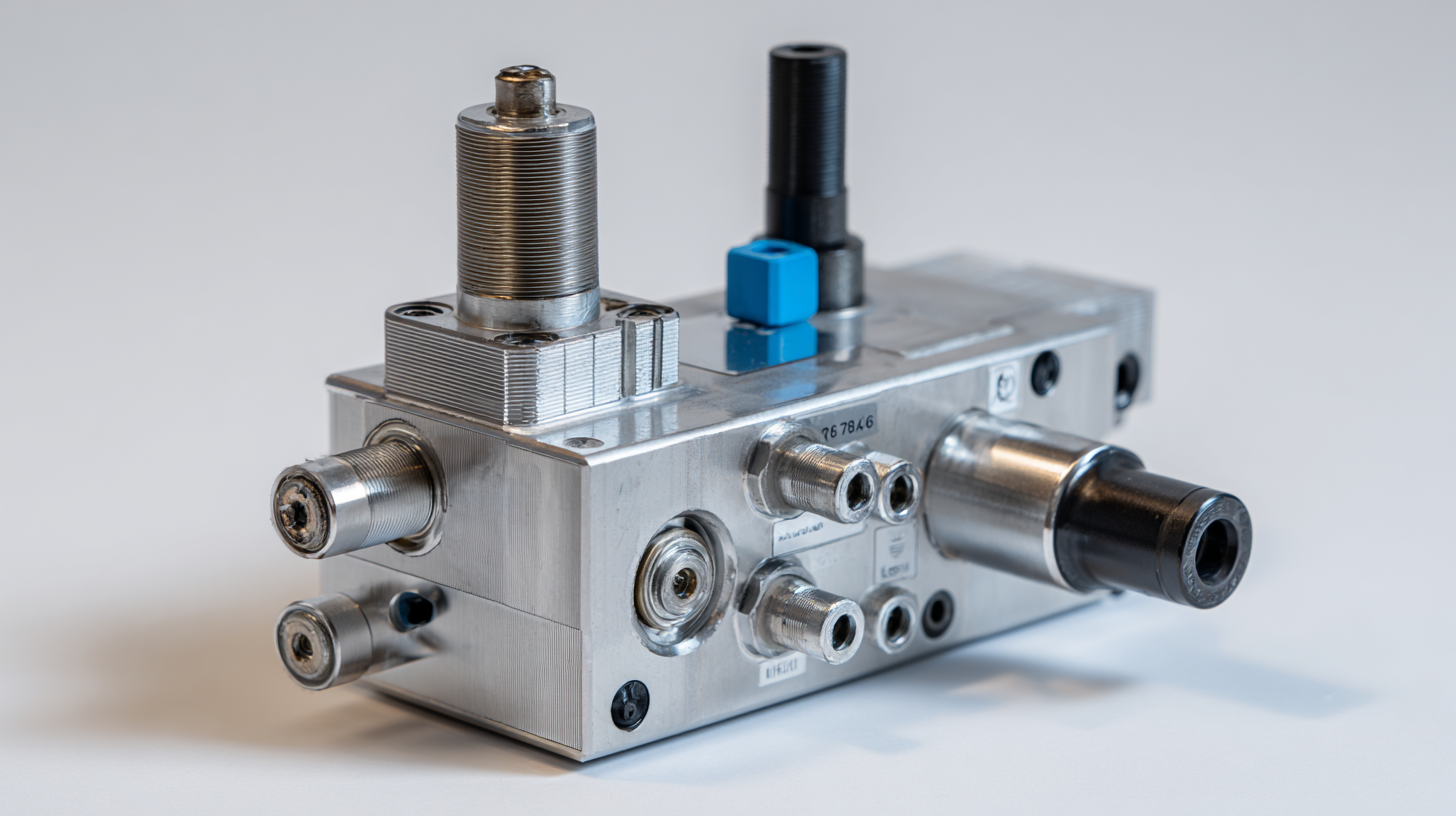

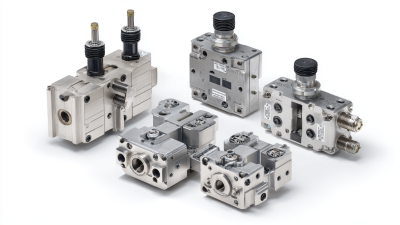

Hydraulic directional control valves play a crucial role in the operation of hydraulic systems across various industries. These valves manage the flow direction of hydraulic fluids, thereby directly influencing the movement and speed of hydraulic actuators such as cylinders and motors. By regulating the flow path, they enable precise control over machinery, ensuring that each component operates efficiently and effectively. The ability to switch directions promptly is essential for applications that require rapid cycles or changes in motion.

The functionality of these valves involves several components, including spools, ports, and actuators. The spool, often considered the heart of the valve, moves within the valve body to open or close different flow paths. The configuration of the ports determines how fluid can enter and exit the system, impacting overall efficiency. Understanding the various types of hydraulic directional control valves, such as poppet valves and spool valves, allows engineers to select the appropriate model for specific applications. This fundamental knowledge not only enhances system performance but also contributes to energy savings and reduced downtime in industrial operations.

Unlocking Efficiency: How Hydraulic Directional Control Valves Boost Industrial Performance by 30%

| Feature | Description | Impact on Performance (%) |

|---|---|---|

| Response Time | Quicker response to operational commands | 10 |

| Operational Efficiency | Optimized fluid flow and control | 15 |

| Energy Consumption | Reduced power usage due to better efficiency | 5 |

| Maintenance Needs | Lower maintenance frequency | 5 |

| Overall System Downtime | Reduced downtime due to efficient operation | 10 |

Key Factors Affecting Industrial Performance Improvements

Hydraulic directional control valves play a crucial role in enhancing industrial performance by optimizing fluid power systems. One of the key factors affecting performance improvements is the efficiency of flow management. By regulating the direction and volume of hydraulic fluid, these valves minimize energy waste and ensure that machines operate at peak capacity. This precise control not only reduces operational costs but also enhances the overall speed of production processes, resulting in a significant boost in efficiency.

Hydraulic directional control valves play a crucial role in enhancing industrial performance by optimizing fluid power systems. One of the key factors affecting performance improvements is the efficiency of flow management. By regulating the direction and volume of hydraulic fluid, these valves minimize energy waste and ensure that machines operate at peak capacity. This precise control not only reduces operational costs but also enhances the overall speed of production processes, resulting in a significant boost in efficiency.

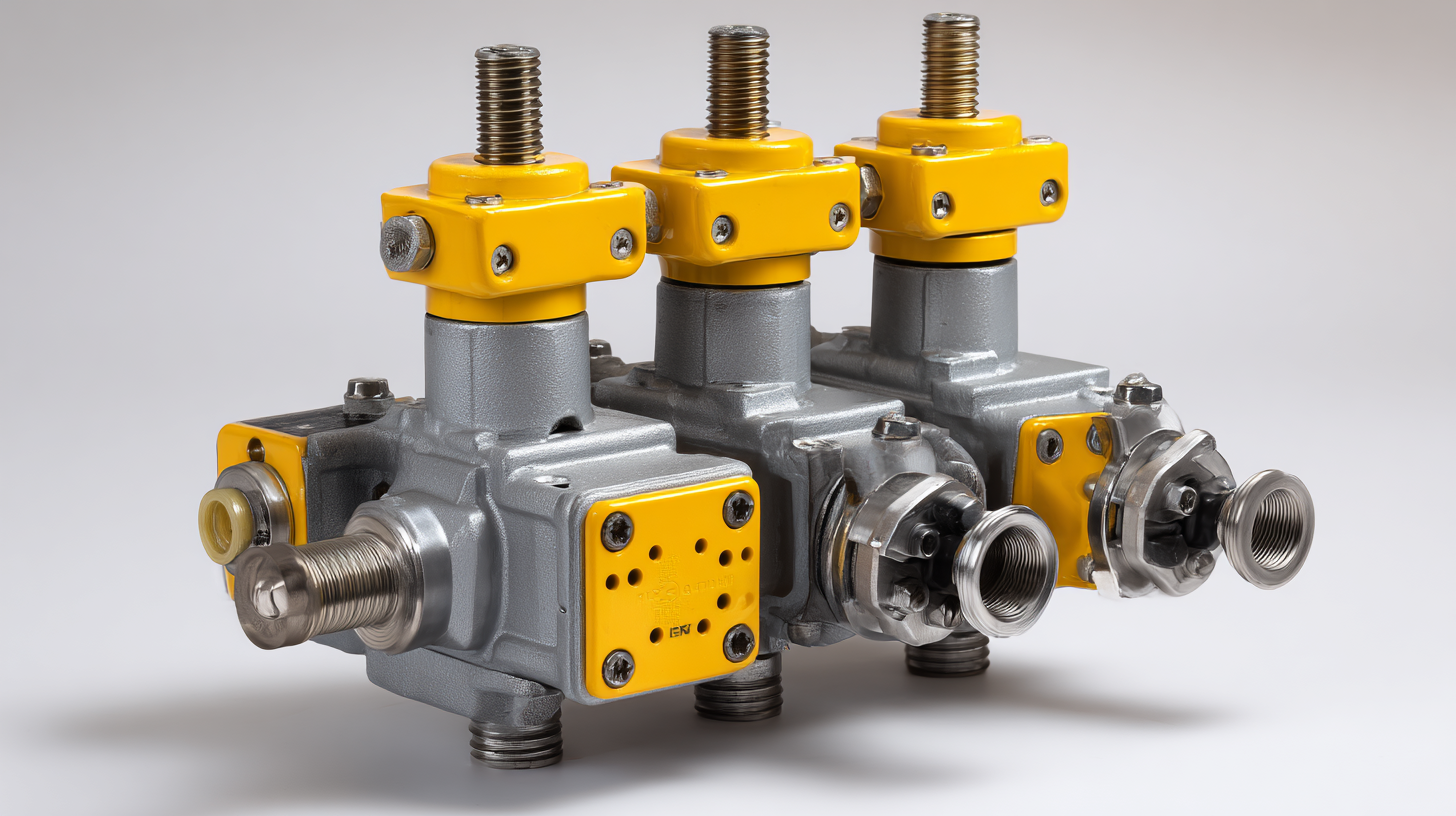

Another important aspect is the adaptability of hydraulic systems to varying operational demands. Advanced directional control valves can be integrated with sensors and automation technology to respond dynamically to changing requirements. This flexibility allows industries to scale operations and adjust fluid delivery seamlessly, which is vital in maintaining competitiveness in fast-paced markets. Furthermore, regular maintenance and timely upgrades of these control systems are essential to sustain their performance, directly impacting the productivity and reliability of industrial operations.

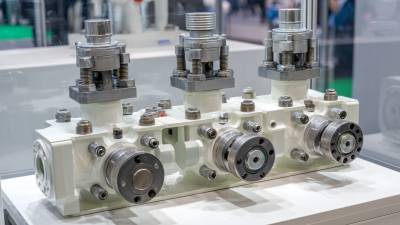

Step-by-Step Guide to Selecting the Right Control Valve for Your System

When selecting the right hydraulic directional control valve for your system, it is crucial to first assess the specific requirements of your application. Begin by determining the flow rate and pressure needed for optimal performance. Understanding the type of fluid, whether it's hydraulic oil or water, also plays a vital role in valve selection. Different fluids may require different materials and sealing options for effective operation and longevity.

Next, consider the design and configuration of the valve. There are various types including spool valves and poppet valves, each suitable for particular operational needs. It's essential to evaluate how the valve will be integrated into your current system and the space available for installation. Additionally, look into the control options available—such as manual, electric, or pneumatic controls—to ensure they align with your operational preferences. By following these steps, you can effectively enhance the performance and efficiency of your industrial system.

Efficiency Improvement with Hydraulic Directional Control Valves

This chart illustrates the performance levels of industrial systems before and after implementing hydraulic directional control valves, showcasing a remarkable improvement of 30% in efficiency.

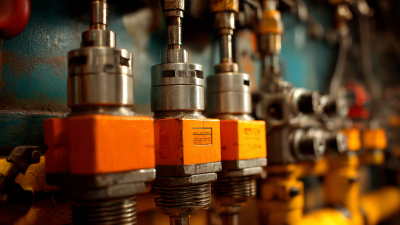

Best Practices for Maintenance to Ensure Optimal Valve Performance

Hydraulic directional control valves are essential components in many industrial applications, playing a key role in optimizing operational efficiency. A maintenance program focused on these valves can lead to a remarkable increase in performance, with industry reports indicating an improvement of up to 30% in productivity when valves are properly maintained. Regular inspection and proactive upkeep not only enhance the lifespan of these components but also minimize downtime—a critical factor in maintaining continuous production flow.

To ensure optimal valve performance, it is crucial to implement best practices in maintenance. Keeping the valves clean and free from debris can prevent mechanical failures and enhance operational reliability. Lubricating moving parts according to manufacturer specifications also reduces wear and prolongs service life. Importantly, adopting a routine schedule for inspections and testing can catch potential issues before they escalate into costly repairs.

**Tips for Maintenance:**

1. Schedule regular cleaning and lubrication of hydraulic components to prevent corrosion.

2. Monitor fluid levels and quality closely; contaminants can significantly affect valve performance.

3. Document maintenance activities to track performance trends and identify areas for improvement over time.

Measuring the Impact of Control Valves on Overall Operational Efficiency

Hydraulic directional control valves play a pivotal role in enhancing industrial operational efficiency. By precisely directing fluid flow within hydraulic systems, these valves ensure that machinery operates at optimal performance levels. The ability to control pressure and direction accurately minimizes energy expenditure and reduces waste, leading to significant improvements in productivity. Facilities utilizing these valves can expect to see performance boosts upwards of 30%, translating to both cost savings and increased output.

Measuring the impact of control valves on overall operational efficiency involves analyzing several key metrics. Maintenance downtime is reduced as valves help prevent system failures caused by fluid mismanagement. Furthermore, industries can achieve better cycle times and increase their production capacity, meeting market demands more effectively. The integration of advanced control valve technologies also allows for real-time monitoring and adjustments, enabling companies to respond swiftly to changing operational conditions, thereby enhancing their competitive edge.

Related Posts

-

Exploring the Future of Hydraulic Control Valves at the 2025 China Import and Export Fair

-

How to Choose the Right Hydraulic Valves for Your Industrial Needs

-

7 Essential Tips for Choosing Hydraulic Flow Control Valves for Your Business

-

How to Choose the Right Hydraulic Check Valve for Your System

-

Addressing Common Hydraulic Flow Control Challenges: Insights and Data from Industry Experts

-

How to Optimize Hydraulic Flow Control Valves for Maximum Efficiency

skip to Main Content

skip to Main Content