2026 How to Choose Pilot Operated Check Valves Effectively?

Choosing the right pilot operated check valves is crucial for system efficiency. Industry expert John Smith notes, “Selecting the appropriate valves can significantly enhance machine performance.” His insight highlights the importance of understanding the specific needs of your application.

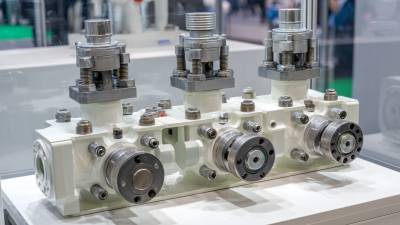

Pilot operated check valves enable fluid flow control, maximizing performance in hydraulic systems. However, not all valves are created equal. Manufacturers often provide various specifications that can confuse users. Factors like cavity size, pressure rating, and material composition must be carefully evaluated. The consequences of poor selection can lead to system failures or inefficiencies, costing both time and money.

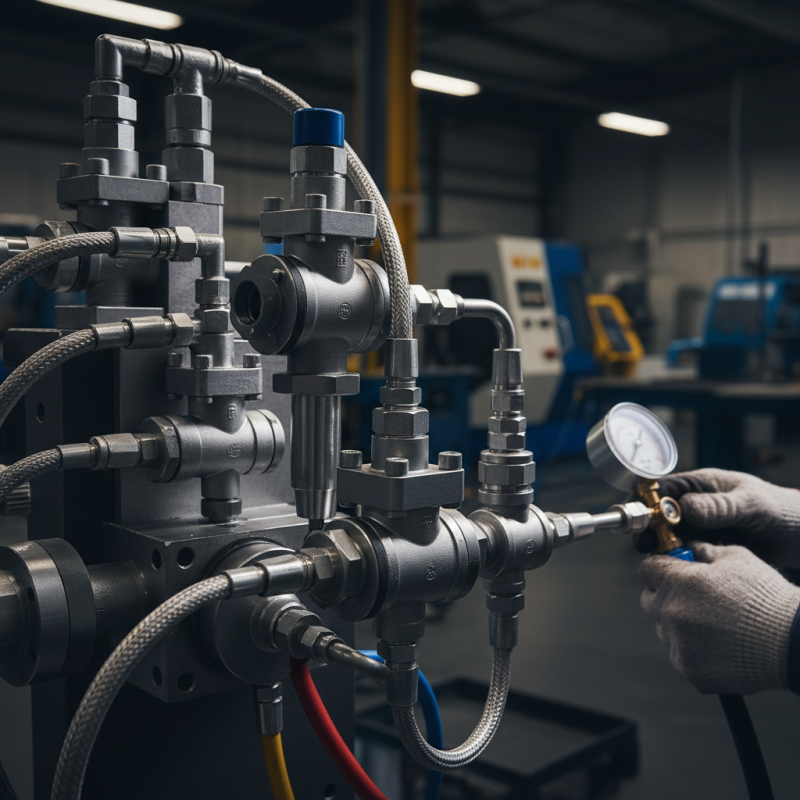

Many users overlook the importance of testing pilot operated check valves in real-world scenarios. Factors like the environment and pressure variations can impact performance. A thoughtful evaluation process, including consultation with experts and thorough testing, can prevent these pitfalls. Adopting a precise approach will not only ensure operational reliability but also improve overall productivity.

Understanding the Functionality of Pilot Operated Check Valves

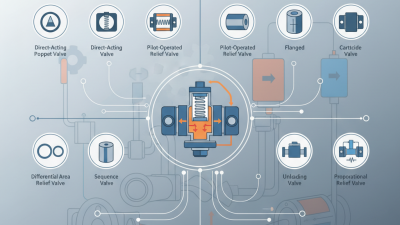

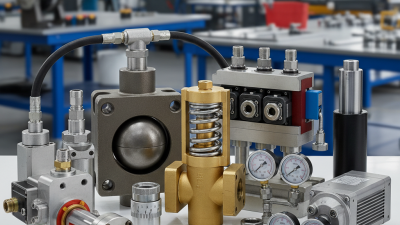

Pilot operated check valves play a crucial role in hydraulic systems. They allow flow in one direction while preventing reverse flow. Understanding their functionality is essential for effective installation and maintenance. These valves consist of a main valve, a pilot valve, and a spring mechanism. When pressure builds, the pilot valve opens, allowing flow. This action moves the main valve off its seat. Once the pressure drops, the spring closes the main valve, preventing backflow.

These components work together to create a reliable system. However, choosing the right pilot operated check valve isn't always straightforward. One must consider factors like fluid type, pressure ratings, and temperature ranges. Misjudging these factors can lead to system failures. Often, professionals overlook the importance of installation angles. An incorrect angle can cause fluid turbulence, reducing efficiency. Visualizing the entire system setup helps in making the right choice.

It's common to encounter challenges when working with these valves. Maintenance is often neglected, leading to wear and tear. Regular inspections can identify issues before they escalate. Another frequent mistake is underestimating the effects of contaminants in fluids. These particles can block the valves over time. Keeping the fluid clean enhances the longevity and performance of pilot operated check valves.

Identifying Key Applications for Pilot Operated Check Valves

When selecting pilot operated check valves, understanding their key applications is crucial. These valves are widely used in industries like hydraulics and pneumatics. Reports suggest that nearly 30% of all industrial fluid control systems employ these valves. They are essential for preventing reverse flow while maintaining system pressure.

One critical application is in hydraulic elevators. Here, pilot operated check valves ensure smooth operation and safety. A malfunction in these systems can lead to severe accidents. According to industry data, installation issues accounted for 15% of failures in hydraulic systems last year. This highlights the need for careful selection based on specific requirements.

Another important application is in hydraulic presses, used in manufacturing. These setups require precise control of hydraulics. Data indicates that efficiency can drop by 20% if the wrong valves are used. Operators often overlook sizing and response time, leading to operational inefficiencies. Selecting the right pilot operated check valve is vital for maintaining performance and safety in such applications.

2026 How to Choose Pilot Operated Check Valves Effectively? - Identifying Key Applications for Pilot Operated Check Valves

| Application Area | Typical Fluid | Pressure Range (psi) | Temperature Range (°F) | Key Benefits |

|---|---|---|---|---|

| Hydraulic Systems | Hydraulic Oil | 500 - 3000 | -20 to 180 | Reliable hold & release |

| Water Treatment | Water | 10 - 150 | 32 to 140 | Prevents backflow |

| Industrial Machinery | Compressed Air | 20 - 250 | 0 to 120 | Compact design |

| Automotive Applications | Motor Oil | 75 - 300 | -40 to 250 | Enhanced safety & efficiency |

| Chemical Processing | Chemical Solvents | 50 - 200 | -10 to 180 | Corrosion resistance |

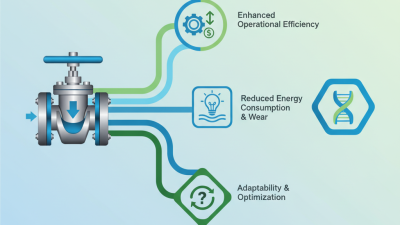

Evaluating the Specifications and Features of Check Valves

When evaluating pilot operated check valves, focus on their specifications and features. It’s crucial to consider the application requirements. Look at the pressure and temperature ratings. These ratings inform how the valve will perform under specific conditions. Lightweight materials and compact designs can enhance installation efficiency.

Tips: Always check the flow direction indicated on the valve. An overlooked detail can lead to malfunction.

Further, assess the valve's response time. Different designs will react at varying speeds. A slower response may not suit critical applications. It’s also essential to understand the materials used. Some materials are more durable than others. Corrosion resistance is a key factor in longevity.

Tips: Make sure to compare different models. Take note of warranty terms, as they can indicate the manufacturer’s confidence.

Inadequate research may lead to choosing the wrong valve type. For instance, some valves may struggle under fluctuating pressures. Always consult technical data sheets for precise information. Defects in design can impact system effectiveness. Awareness of these aspects can lead to better decision-making.

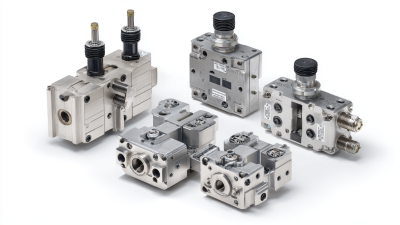

Comparing Different Manufacturers and Their Products

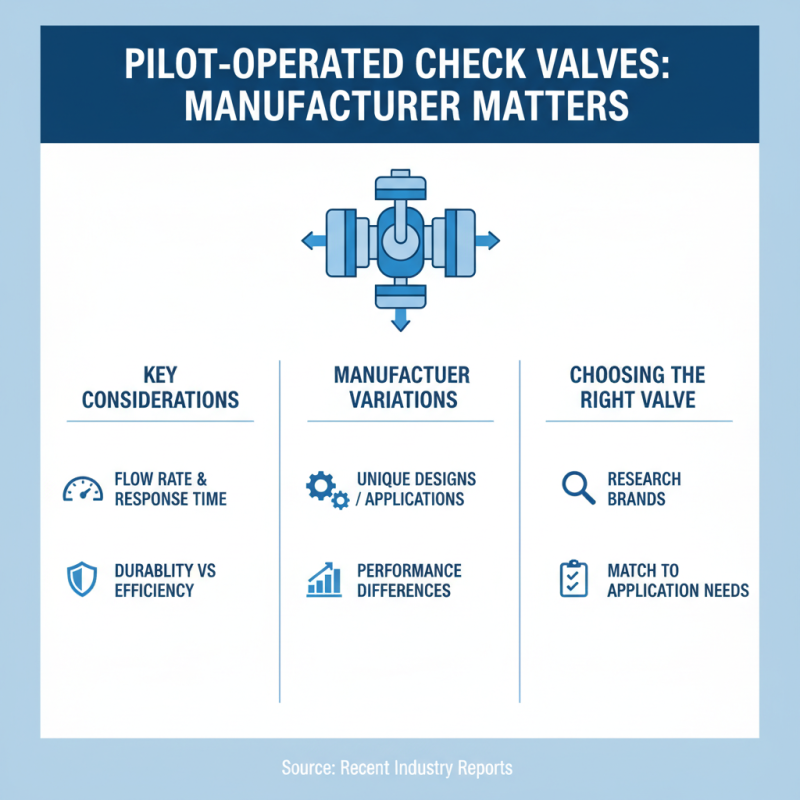

When choosing pilot operated check valves, understanding different manufacturers is key. Each company offers unique products designed for various applications. Recent industry reports indicate that performance can vary significantly among brands. For instance, flow rates and response times are often critical in selecting the right valve. Some manufacturers emphasize durability, while others focus on efficiency.

**Tip:** Always consider the specific conditions of your application. Different materials and designs can affect valve performance in high-pressure systems.

It's crucial to analyze feedback from projects similar to yours. Common issues include valve sticking or improper sealing, which can lead to inefficiency. Understanding these pitfalls can help you choose wisely.

**Tip:** Request performance data sheets to compare options effectively. Look for certifications that ensure quality and reliability. This step can save you from costly repairs in the future.

Maintenance and Troubleshooting Tips for Pilot Operated Check Valves

Pilot operated check valves are essential components in hydraulic systems. Regular maintenance ensures smooth operation. Inspect the valves for wear or damage. Look for leaks and unusual sounds. These signs can indicate a problem that needs attention.

To troubleshoot effectively, start with a visual inspection. Check the pilot line and ensure it’s not clogged. Low pressure can be due to a blocked line. If a valve is not closing properly, there may be debris inside. Cleaning can often resolve this. Be cautious; sometimes, disassembly might be necessary.

Consider the environment where the valves operate. Temperature extremes can affect performance. Dust and moisture can also contribute to issues. Keeping the surrounding area clean helps longevity. If problems persist, it may be time to reflect on the design choices made during selection. Not every type of valve suits every application. Testing alternatives might be beneficial for future setups.

Related Posts

-

Top 10 Hydraulic Pressure Relief Valves for Optimal Equipment Performance

-

Exploring the Future of Hydraulic Control Valves at the 2025 China Import and Export Fair

-

Top 10 Hydraulic Controls You Should Know About?

-

Top Benefits of Using Pump Valves for Efficient Fluid Control

-

Top 2025 Control Valves: Features, Trends, and Buying Guide

-

How to Optimize Hydraulic Flow Control Valves for Maximum Efficiency

skip to Main Content

skip to Main Content