The Ultimate Guide to Pressure Regulating Valves and Their Applications

Pressure regulating valves (PRVs) play a crucial role in various industries, ensuring that systems operate at safe and optimal pressure levels. As noted by industry expert Dr. Michael Anderson, who specializes in fluid dynamics, “Pressure regulating valves are essential components that not only protect equipment but also enhance the efficiency and reliability of fluid control systems.” His insight underscores the importance of understanding how these valves function and their diverse applications across sectors such as water distribution, oil and gas, and manufacturing.

In this comprehensive guide, we will explore the mechanics of pressure regulating valves, including their design, operational principles, and types available on the market. Furthermore, we will delve into the specific applications of PRVs, illustrating their vital role in maintaining system integrity and performance. Whether you are an engineer, technician, or simply interested in the field, this guide will equip you with essential knowledge about pressure regulating valves, helping you make informed decisions for your projects.

Understanding Pressure Regulating Valves: Definition and Function

Pressure regulating valves are essential components in various fluid systems, controlling the pressure of gases and liquids to maintain safe and effective operation. Their primary function is to automatically modulate the pressure downstream, ensuring that it remains within a predetermined range regardless of fluctuations in the upstream pressure. This is particularly crucial in applications where excessive pressure could lead to system failures, safety hazards, or inefficiencies.

These valves operate based on a simple yet effective mechanism, utilizing a diaphragm or piston that responds to changes in pressure. When the downstream pressure exceeds the set point, the valve closes partially or fully to reduce the flow, lowering the pressure. Conversely, if the pressure falls below the set point, the valve opens, allowing more flow to increase the pressure. This self-adjusting feature makes pressure regulating valves indispensable in sectors such as water supply, HVAC systems, and industrial processes, where maintaining optimal pressure is vital for operational reliability and safety.

Types of Pressure Regulating Valves: A Comprehensive Overview

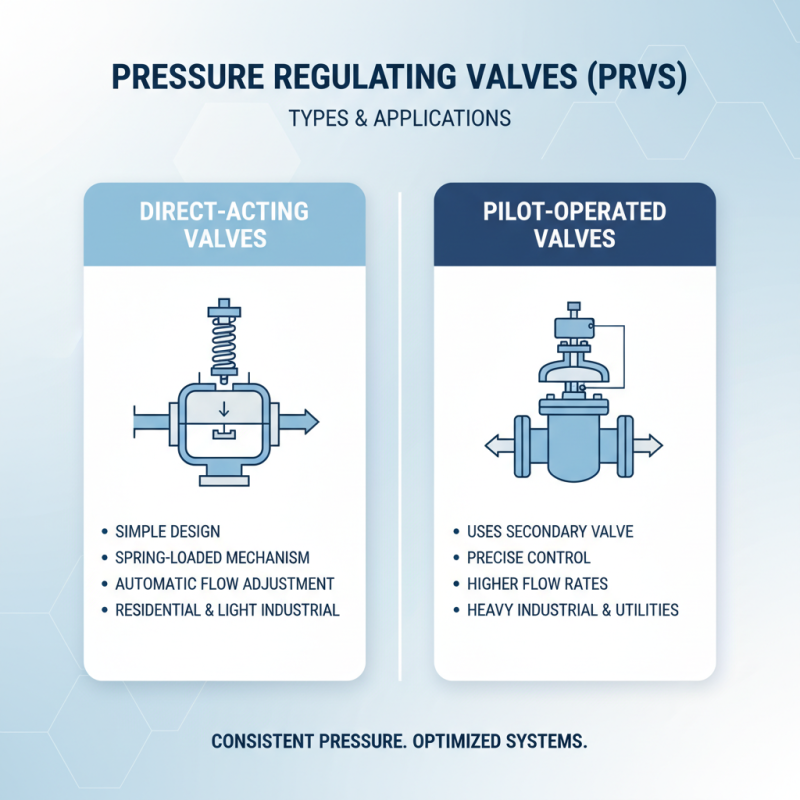

Pressure regulating valves (PRVs) are critical components in various industrial and residential systems, helping to maintain a consistent outlet pressure regardless of fluctuations in the supply pressure. There are several types of pressure regulating valves, each designed for specific applications and operating conditions. The most common types include direct-acting valves, which use a spring-loaded mechanism to automatically adjust the flow based on system pressure, and pilot-operated valves, which utilize a secondary valve to control the flow of the main valve. This diversity allows engineers to select the most suitable valve type for their needs.

When choosing the right PRV, pay attention to factors such as pressure range, flow capacity, and the fluid type involved. For instance, direct-acting valves are often preferred for low flow applications due to their quick response times, while pilot-operated valves are ideal for high flow systems because they can handle larger volumes with enhanced stability.

Tips for optimal performance include regular maintenance checks to prevent wear and tear, and ensuring that valves are installed in the correct orientation to avoid operational issues. Always consult the manufacturer’s specifications to match the valve with your system's requirements effectively. Implementing proper sizing and installation techniques will not only enhance efficiency but also prolong the life of the PRV, ensuring reliable operation in various applications.

Applications of Pressure Regulating Valves in Various Industries

Pressure regulating valves (PRVs) play a crucial role in various industries by maintaining desired pressure levels, ensuring the safety and efficiency of systems. In the oil and gas industry, for example, PRVs are essential in managing the pressure of crude oil extraction and natural gas processing. According to a report by the International Energy Agency, the global oil demand is projected to reach 104 million barrels per day by 2026, necessitating reliable pressure management systems. Effective PRVs help prevent pressure surges and equipment failures, which can be costly and hazardous.

In the water and wastewater treatment sectors, PRVs are critical for maintaining optimal pressure for plumbing and distribution systems. The Water Environment Federation highlights that aging infrastructure in water supply systems leads to water loss through leaks, with up to 30% of treated water being wasted. Installing PRVs can help reduce pressure in vulnerable areas of the network, minimizing leaks and ensuring a more sustainable water supply. Furthermore, in pharmaceutical manufacturing, maintaining precise pressure levels can be vital for ensuring the quality and safety of products, with the FDA emphasizing the necessity of strict quality controls in production environments.

Ultimately, the versatility of pressure regulating valves across diverse applications underscores their importance in enhancing operational efficiency and safety in multiple sectors. As industries face increasing demands and challenges, the implementation of reliable pressure regulation solutions will remain essential for sustainable operations.

How to Select the Right Pressure Regulating Valve for Your Needs

When selecting the right pressure regulating valve for your specific needs, it is essential to consider several key factors that influence performance and efficiency. First and foremost, you must identify the application requirements, including the type of fluid being regulated, the pressure range, and the flow rate. Understanding these parameters helps narrow down the options and ensures compatibility with your existing system. Additionally, you should consider the valve's construction materials, especially if the medium is corrosive or involves extreme temperatures, to ensure durability and longevity.

Another critical aspect is the valve’s control mechanism. Pressure regulating valves can be classified into different types, including spring-loaded, pilot-operated, and electronic. Each type has unique advantages that can affect operational efficiency and accuracy. For example, electronic valves may provide more precise control in automated systems, while pilot-operated valves offer enhanced stability for larger flow rates. It's advisable to engage with suppliers or industry professionals who can provide insights based on your specific operational context, ensuring you make an informed choice that maximizes performance and minimizes potential issues in your application.

Installation and Maintenance Best Practices for Pressure Regulating Valves

When it comes to ensuring optimal performance in fluid systems, the installation and maintenance of pressure regulating valves (PRVs) play a crucial role. Proper installation starts with selecting an appropriate location that minimizes exposure to harmful conditions such as extreme temperatures or vibrations. It is essential to install the PRV in a vertical position when possible, allowing for proper drainage of condensates and to prevent unwanted liquid accumulation. Always refer to manufacturer guidelines for specific installation instructions, as variations can exist.

Tips: Before beginning the installation, make sure to thoroughly inspect all components for damage or wear. Ensuring that all connections are tight and leak-free is essential to the longevity and efficiency of the valve. Additionally, the use of appropriate sealing materials can help mitigate any potential issues.

Maintenance of PRVs involves regular inspection and testing to ensure they are functioning correctly. Checking for signs of wear and tear, such as leaks or excessive noise, can help identify issues before they lead to system failures. It is recommended to establish a maintenance schedule based on the operational conditions and the manufacturer’s recommendations. Furthermore, cleaning any debris from the valve and surrounding areas can prevent blockages and promote smooth operation.

Tips: Keep a log of maintenance activities and any changes to the system environment, as this information can be invaluable when troubleshooting future issues. Regular training for personnel involved in the maintenance process can also enhance the safety and efficiency of operations.

The Ultimate Guide to Pressure Regulating Valves and Their Applications

| Dimension | Description | Typical Applications | Maintenance Frequency | Installation Tips |

|---|---|---|---|---|

| Inlet Pressure Range | The pressure incoming to the valve | Water Supply, Gas Distribution | Monthly | Ensure proper anchoring |

| Outlet Pressure Setting | The pressure at which the valve maintains output | Industrial, HVAC Systems | Quarterly | Calibrate settings accurately |

| Material | Construction material of the valve | Chemical Processing, Oil and Gas | Annually | Use corrosion-resistant materials |

| Size | Diameter of the valve inlet and outlet | Agricultural Irrigation, Plumbing | Every 6 months | Follow manufacturer's specifications |

| Connection Type | How the valve connects to piping | Water Systems, Gas Lines | As needed | Ensure tight fittings |

Related Posts

-

What are the Benefits of Using Pressure Valves in Industrial Applications

-

7 Best Pressure Reducing Valves You Should Consider for Optimal Performance

-

Essential Checklist for Selecting the Right Hydraulic Check Valves for Your Applications

-

What is an Electric Valve? Understanding Types, Applications, and Benefits

-

What is the Future of Automated Valves in Modern Industries

-

Exploring Innovative Alternatives in Control Valves: A Global Purchasing Perspective

skip to Main Content

skip to Main Content