Exploring the Future: Top Fluid Power Hydraulics Trends for 2025+

In the rapidly evolving landscape of industrial technology, fluid power hydraulics continues to play a pivotal role in enhancing efficiency and performance across various sectors. As we look ahead to 2025 and beyond, it is essential to explore the emerging trends that are set to shape the future of this integral field. The advancements in fluid power hydraulics are expected to not only improve mechanical systems but also pave the way for smarter, more sustainable industrial processes.

One of the most significant trends on the horizon is the integration of IoT and automation technologies into fluid power systems. This integration promises to usher in an era of enhanced monitoring and control, allowing for real-time data analysis and predictive maintenance, ultimately leading to increased operational efficiency. Furthermore, the growing emphasis on sustainability is driving innovation in fluid power hydraulics, with a focus on reducing energy consumption and minimizing environmental impact. As we delve into these trends, it becomes evident that the future of fluid power hydraulics is bright, presenting numerous opportunities for advancement and growth in various industries.

Emerging Technologies in Fluid Power: Shaping Hydraulics for 2025 and Beyond

The landscape of fluid power hydraulics is poised for significant transformation as we approach 2025. Emerging technologies, particularly in solar, wind, hydrogen, and energy storage, are driving this change and presenting both opportunities and challenges for the industry. According to recent industry reports, the market for renewable energy technologies is expected to reach over $1 trillion by 2025, underscoring the urgency for hydraulics systems to adapt and integrate these innovations.

The incorporation of advanced materials and smart technologies in fluid power systems is crucial. For instance, the use of IoT-enabled devices can enhance system efficiency by providing real-time data for predictive maintenance. As energy sectors increasingly rely on hybrid systems combining hydraulics and electric power, maintaining compatibility with renewable sources will be a critical challenge.

**Tip:** To remain competitive, hydraulics manufacturers should invest in upskilling their workforce in new technologies and adopt agile manufacturing practices that allow quick integration of innovations. Additionally, collaborating with research institutions can facilitate knowledge transfer and accelerate the development of cutting-edge hydraulic solutions suitable for renewable applications.

Exploring the Future: Hydraulics Trends for 2025+

Sustainability Initiatives: Eco-Friendly Practices in Fluid Power Systems

The pursuit of sustainability has become increasingly vital in the field of fluid power hydraulics. As we approach 2025 and beyond, the industry is actively exploring eco-friendly practices that minimize environmental impact while maintaining operational efficiency. The shift towards renewable energy sources, such as bio-hydraulic fluids and energy-saving hydraulic systems, exemplifies this movement. These innovations not only reduce the carbon footprint but also enhance system performance and longevity.

Another significant trend is the integration of advanced technologies to optimize fluid power systems. Implementing smart sensors and IoT devices enables real-time monitoring of hydraulic systems, allowing for predictive maintenance and reduced energy consumption. By leveraging data analytics, companies can identify inefficiencies and implement changes that lead to more sustainable operations. Moreover, incorporating recyclable materials into hydraulic components further contributes to a circular economy, making fluid power systems more environmentally responsible.

Exploring the Future: Top Fluid Power Hydraulics Trends for 2025+

| Trend | Description | Impact on Sustainability | Projected Adoption Rate (% by 2025) |

|---|---|---|---|

| Energy Efficiency Improvements | Advancements in components leading to less energy consumption. | Reduces carbon footprint and operational costs. | 75% |

| Smart Hydraulics | Integration of IoT technologies for real-time monitoring. | Enhances system reliability and minimizes waste. | 60% |

| Alternative Fluids | Use of bio-based and environmentally friendly hydraulic fluids. | Decreases environmental impact and increases recyclability. | 50% |

| Modular Systems | Design of systems that can be easily expanded or modified. | Reduces material waste and improves resource utilization. | 65% |

| Digital Twins | Creation of digital replicas for improved analysis and performance. | Optimizes maintenance and reduces downtime, thus saving resources. | 55% |

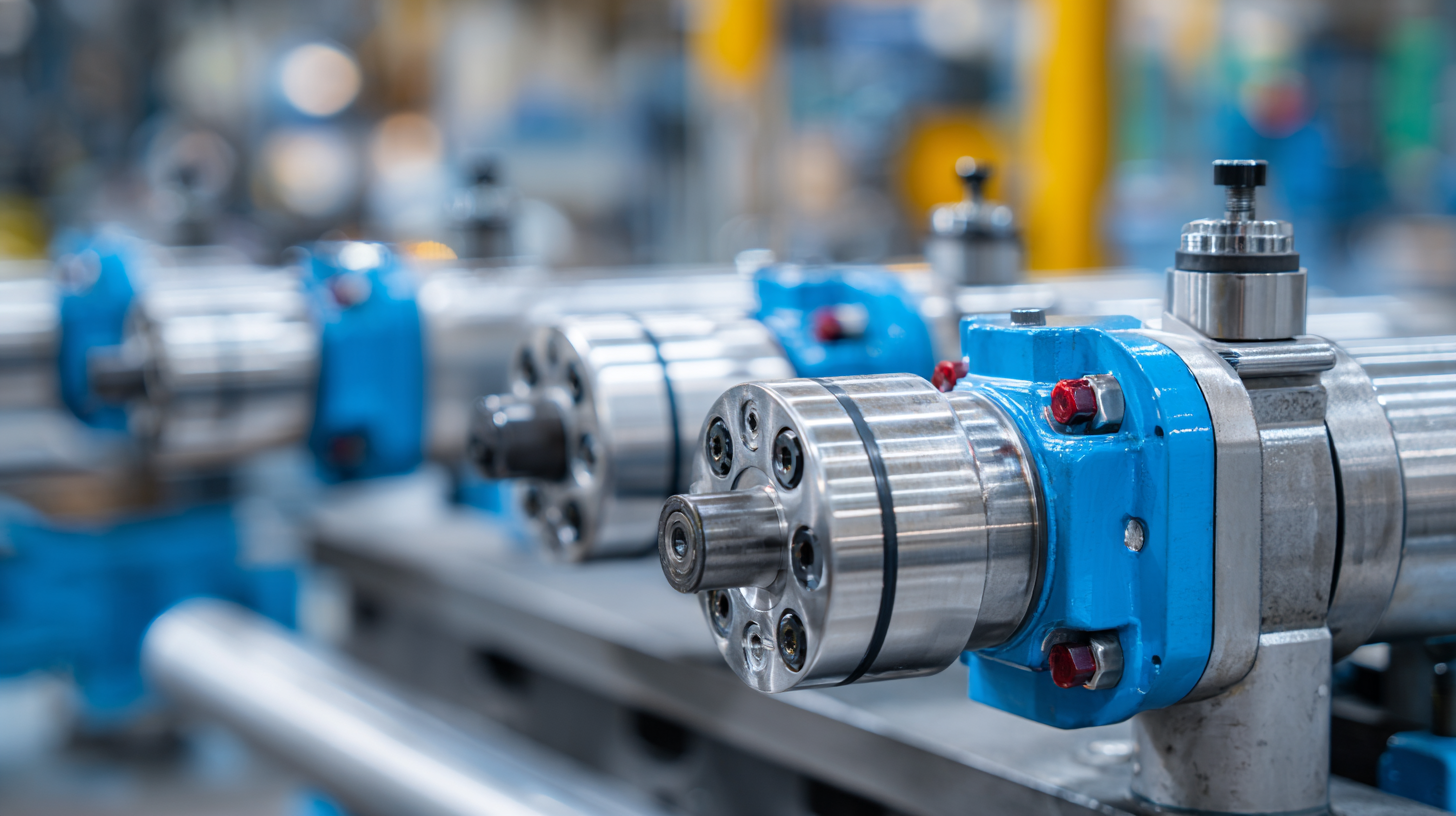

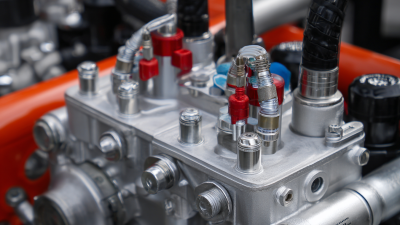

Smart Hydraulics: Integrating IoT and Automation for Enhanced Performance

The integration of IoT and automation into fluid power hydraulics is poised to revolutionize the industry by enhancing performance and efficiency. As the demand for smart hydraulics grows, the global hydraulic valve market is projected to reach $770 million by 2025, with a steady increase to $1.16 billion by 2033, reflecting a compound annual growth rate (CAGR) of 5.2%. This trend indicates a robust shift towards advanced hydraulic systems that leverage connectivity and data analytics to optimize operations.

Moreover, the market for smart hydraulic excavators is also expanding significantly. Valued at approximately $1.23 billion in 2022, this segment is expected to surge to $2.45 billion by 2030, achieving an impressive CAGR of 9.2% from 2024 to 2030. The adoption of these technologies not only improves operational efficiency but also enables predictive maintenance and real-time adjustments to hydraulic systems, catering to the increasing demand for automation in construction and industrial applications. As these trends unfold, the future of fluid power hydraulics will be marked by smarter, more responsive, and more efficient systems, setting a new benchmark for performance in the industry.

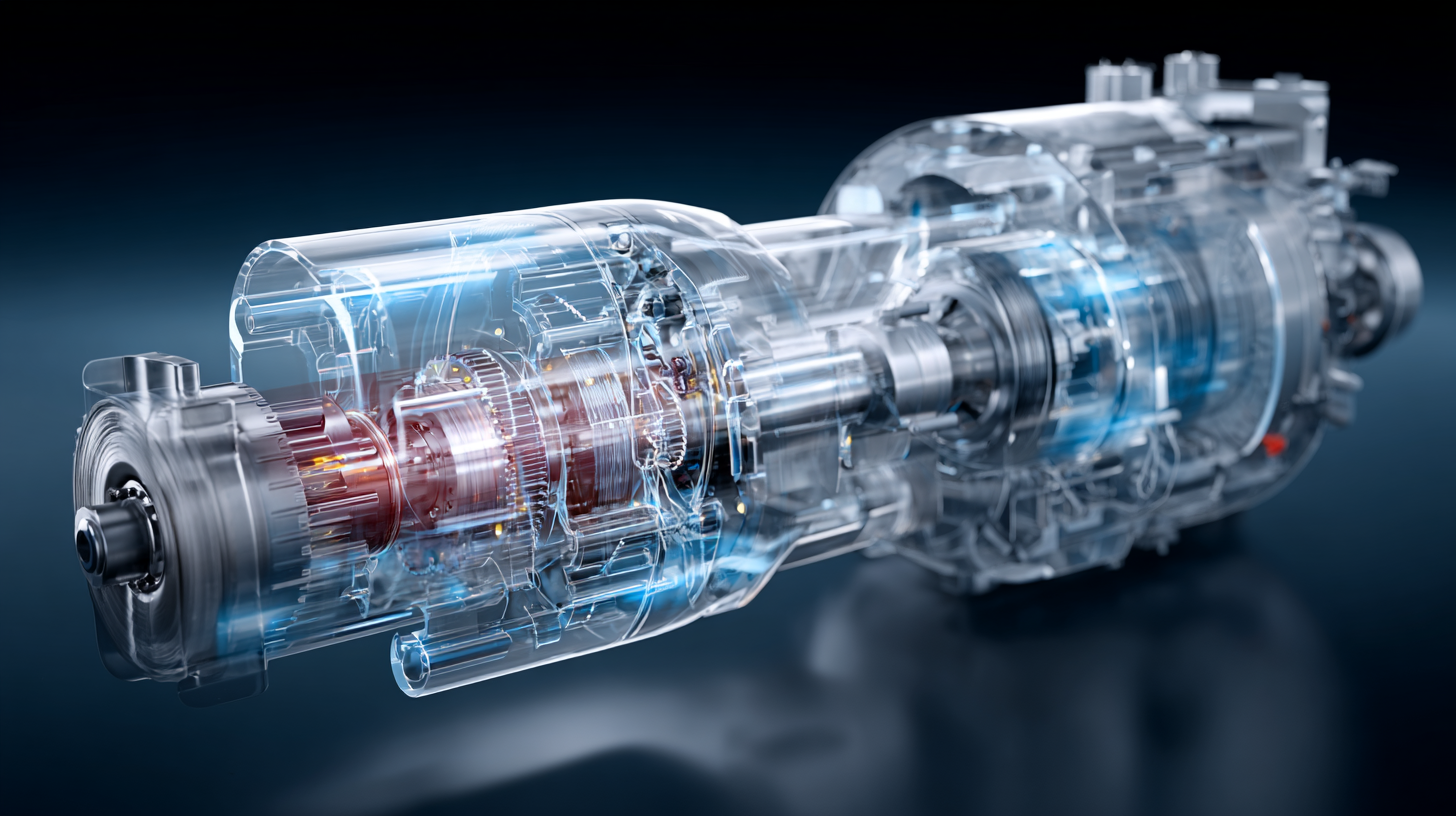

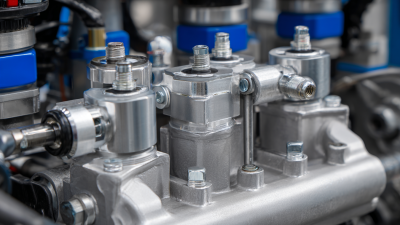

Advanced Materials: Innovations Driving Efficiency in Hydraulic Components

The future of fluid power hydraulics is set to be revolutionized by advancements in materials used for hydraulic components. As industries push for greater efficiency and sustainability, the integration of advanced materials such as composite polymers and high-strength alloys is becoming paramount. These innovations not only reduce the weight of hydraulic systems, enhancing their performance, but also improve their resistance to wear and corrosion, extending their lifespan significantly.

Tips: When selecting materials for hydraulic components, consider their thermal stability and resistance to chemical degradation. Lightweight materials can lead to more energy-efficient systems, so prioritize options that maintain strength while reducing mass.

Furthermore, the rise of smart materials, capable of reacting to environmental changes, offers exciting possibilities. These materials can adapt to pressure variations and temperature fluctuations in real-time, ensuring optimal performance under varying operational conditions. The incorporation of these smart technologies will likely lead to more responsive and reliable hydraulic systems in the near future.

Tips: Stay informed about the latest developments in smart material technology and consider their applicability in your existing hydraulic systems to enhance functionality and adaptability. Emphasizing training on these materials will also prepare teams for the changes ahead.

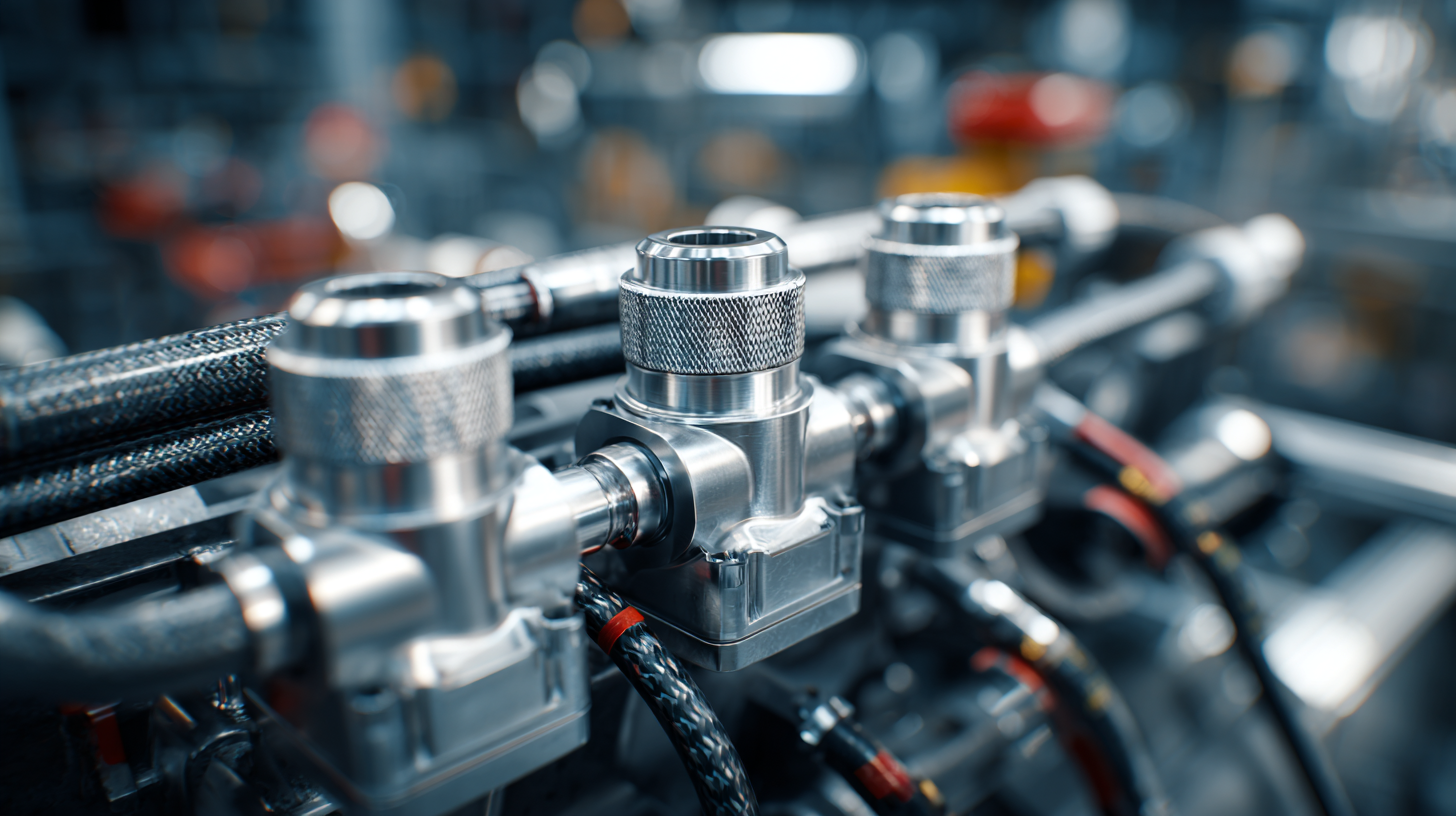

Predictive Maintenance: Utilizing AI for Proactive Fluid Power Management

Predictive maintenance is set to revolutionize fluid power management by leveraging artificial intelligence (AI) for enhanced operational efficiency and reduced downtime. As hydraulic systems become increasingly complex, traditional maintenance approaches often fall short, leading to unexpected failures and costly repairs. By integrating AI into fluid power systems, organizations can utilize data analytics to monitor equipment health in real-time, allowing for timely interventions before minor issues escalate into significant problems.

AI algorithms can analyze vast amounts of operational data to identify patterns and predict when maintenance should be performed. This proactive approach minimizes disruptions, ensures optimal performance, and extends the lifespan of hydraulic components. Moreover, with machine learning capabilities, these systems continuously improve their predictive accuracy over time, adapting to unique operational conditions. As a result, companies can not only enhance productivity but also achieve significant cost savings through efficient resource allocation and reduced unplanned maintenance events. The future of fluid power management is thus not just about keeping systems running but about harnessing the power of AI to create smarter, more resilient hydraulic solutions.

Related Posts

-

Why Fluid Power Hydraulics Are Essential for Modern Industry

-

Exploring the Future of Fluid Power Hydraulics in Innovative Industries

-

5 Best Fluid Power Hydraulics Solutions for Optimal Performance

-

Ultimate Checklist for Global Buyers in Fluid Power Procurement

-

What Are the Key Components of Hydraulics Products and Their Applications

-

Exploring Hydraulic Continental Solutions at the 138th Canton Fair 2025 Trends and Market Data

skip to Main Content

skip to Main Content