Why Fluid Power Hydraulics Are Essential for Modern Industry

Fluid power hydraulics play a pivotal role in modern industry, serving as the backbone for various applications ranging from manufacturing to construction. According to a report by the Fluid Power Association, the global fluid power market is projected to reach approximately $100 billion by 2025, driven by the increasing demand for efficient and reliable power systems. Fluid power hydraulics, known for their ability to transmit energy through liquid under pressure, provide unparalleled advantages such as greater torque, precise control, and enhanced safety in operations. Industries deploying hydraulic systems can increase productivity by over 20%, as outlined in a study published by the International Journal of Engineering Trends and Technology. As technological innovations continue to advance, the integration of fluid power hydraulics in automation and robotics is expected to further streamline processes and reduce operational costs, making it indispensable for the evolving landscape of modern industry.

Importance of Fluid Power Hydraulics in Industrial Applications

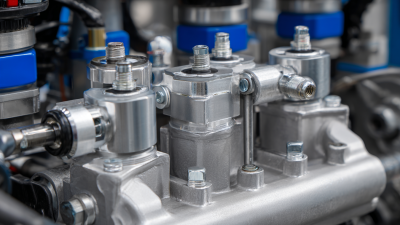

Fluid power hydraulics play a crucial role in modern industrial applications, offering numerous advantages that enhance operational efficiency and productivity. By utilizing pressurized fluids, hydraulic systems can generate immense force and power while maintaining precise control over machinery. This capability is essential in various sectors, including construction, manufacturing, and transportation, where heavy lifting and precise movements are necessary.

One of the primary benefits of fluid power hydraulics is their ability to perform tasks that require significant torque. For instance, hydraulic systems are commonly used in excavators and forklifts, enabling them to lift heavy loads with ease. Additionally, the adaptability of hydraulic systems allows for integration into automated processes, making them invaluable in modern factories that rely on precision and speed. The maintenance of hydraulic systems is also generally straightforward, contributing to their popularity in settings where reliability and minimal downtime are critical. As industries continue to evolve, the significance of fluid power hydraulics remains a pivotal component in driving innovation and efficiency.

Importance of Fluid Power Hydraulics in Industrial Applications

Key Advantages of Hydraulics Over Other Power Systems

Fluid power hydraulics play a pivotal role in modern industry, offering several key advantages over traditional power systems. One of the most notable benefits is the exceptional power-to-weight ratio that hydraulic systems provide. According to a report by the International Fluid Power Society, hydraulic systems can transmit power more efficiently than electric or pneumatic alternatives, enabling machinery to deliver greater force with less weight. This translates to reduced energy consumption and improved operational efficiency, making hydraulics particularly advantageous in industries like manufacturing and construction where heavy lifting is common.

Furthermore, hydraulic systems are renowned for their versatility and responsiveness. With the ability to easily control the speed and force of machinery, hydraulics allow for precise adjustments in various applications, from automated assembly lines to mobile equipment. A study conducted by the National Fluid Power Association indicates that 70% of industrial processes utilize hydraulic systems due to these attributes, which contribute to higher productivity rates and lower operational costs.

Tips: When selecting hydraulic systems for your operations, consider investing in advanced technologies that enhance control and maintenance, such as real-time monitoring systems. Additionally, regularly scheduled preventive maintenance can prolong the life of hydraulic components, ensuring sustained efficiency and reliability.

Why Fluid Power Hydraulics Are Essential for Modern Industry - Key Advantages of Hydraulics Over Other Power Systems

| Advantage | Description | Typical Application |

|---|---|---|

| High Power-to-Weight Ratio | Hydraulic systems can generate large forces from relatively small components. | Construction equipment, such as excavators. |

| Precision Control | Hydraulic systems can offer fine control over speed and force. | Manufacturing robots, CNC machines. |

| Durability and Reliability | Hydraulic components are robust and can withstand harsh conditions. | Mining and heavy-duty applications. |

| Versatility | Hydraulics can be used in a wide range of applications and industries. | Agricultural machinery, automotive systems. |

| Immediate Response | Hydraulic systems can react instantly to changes in control input. | Aerospace applications, automotive braking systems. |

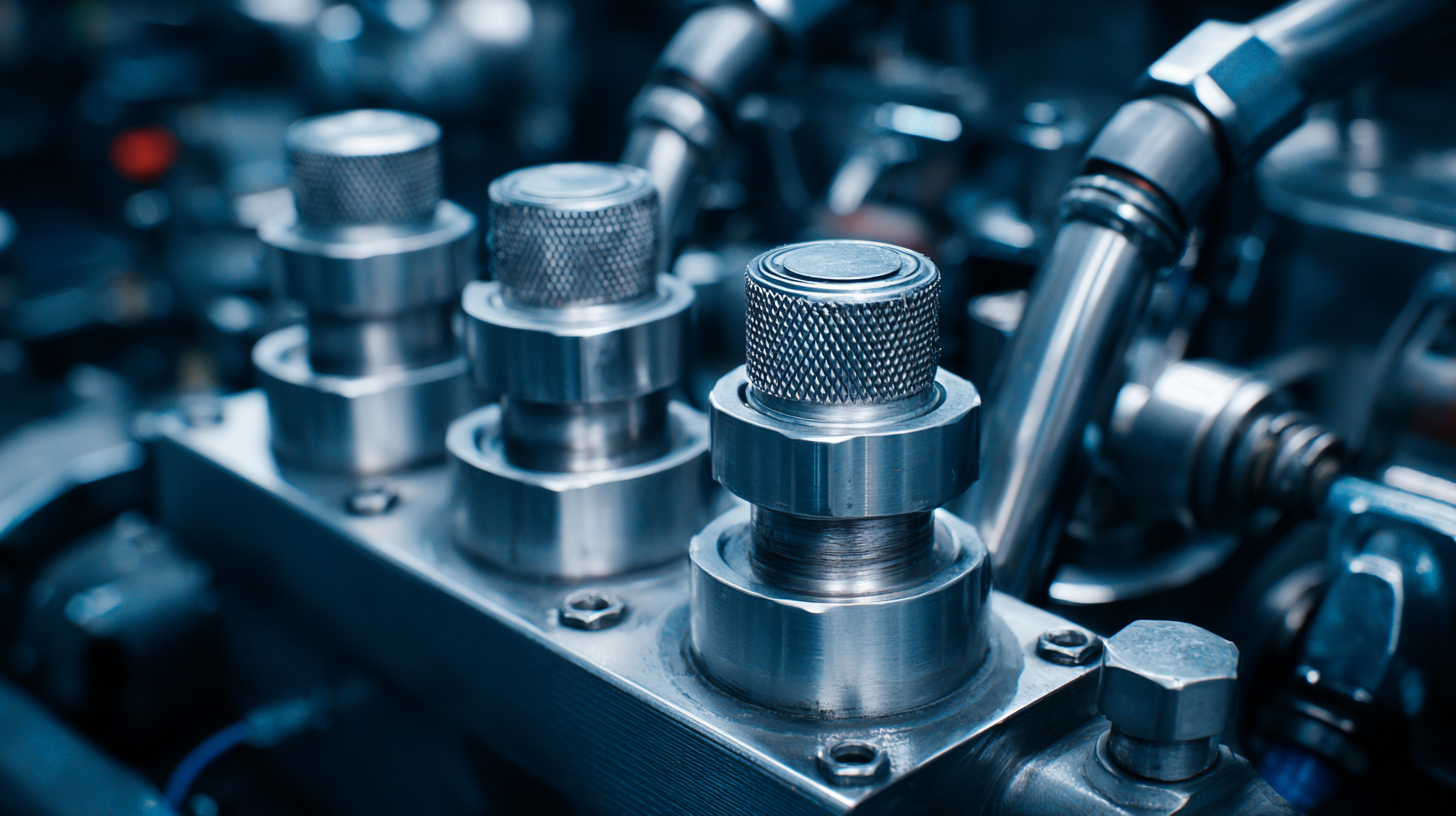

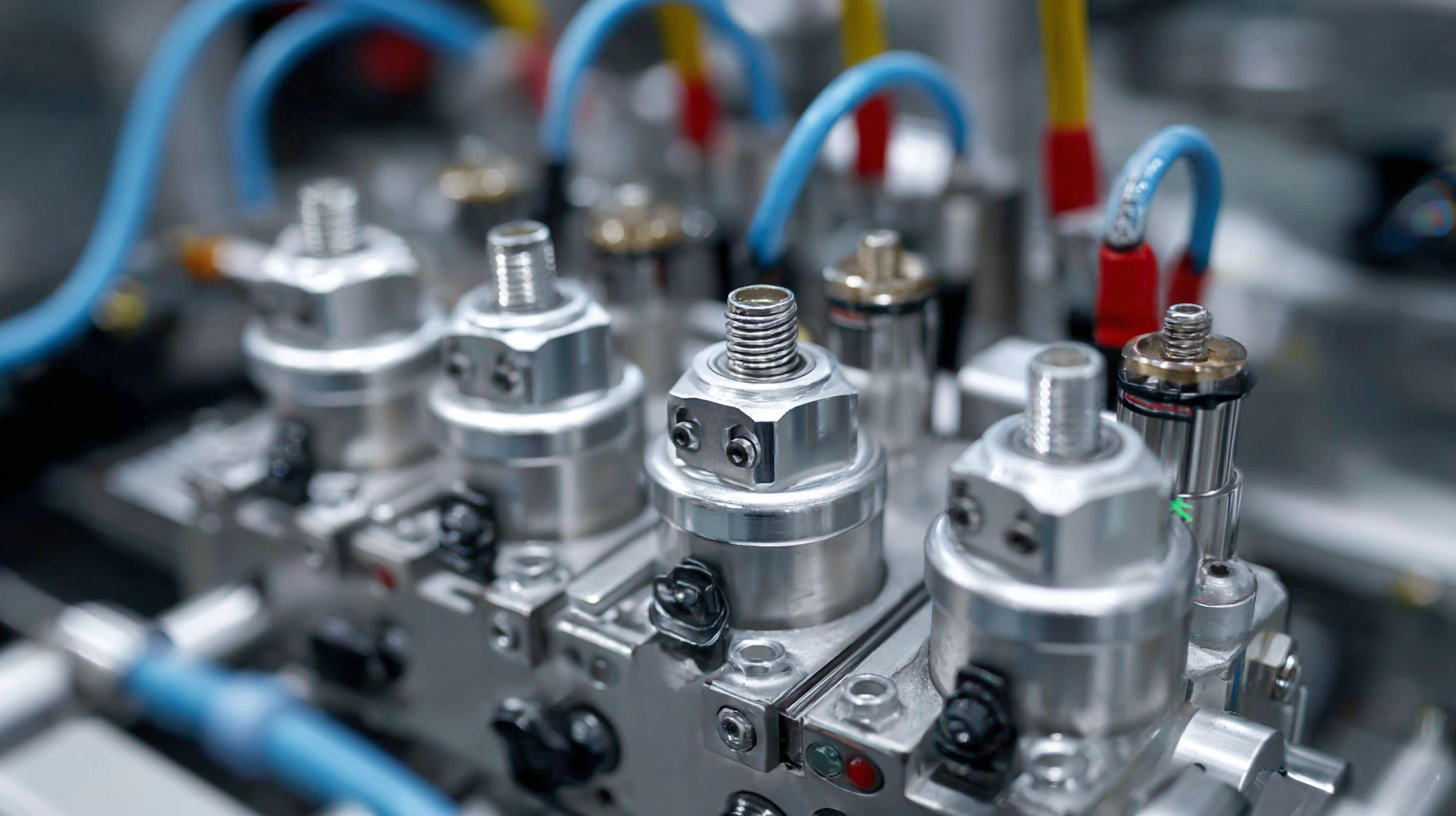

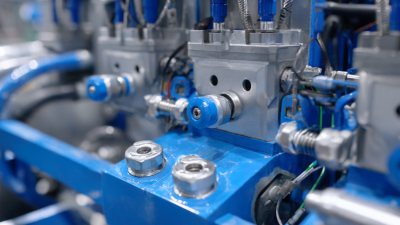

Essential Components of Fluid Power Hydraulic Systems

Fluid power hydraulics play a crucial role in modern industrial applications, serving as the backbone for various operations. Central to these systems are essential components such as pumps, actuators, valves, and reservoirs. According to the International Fluid Power Society, the fluid power industry is projected to grow at a CAGR of 5.5% through 2025, emphasizing the increasing reliance on hydraulic systems in sectors such as manufacturing, construction, and automotive.

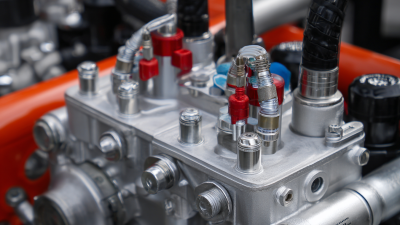

Pumps are the heart of hydraulic systems, converting mechanical energy into hydraulic energy. They come in various types, including gear, vane, and piston pumps, each suited for different applications based on efficiency and pressure requirements. Actuators, which include hydraulic cylinders and motors, transform hydraulic energy back into mechanical work, enabling precise control of machinery. Valves regulate fluid flow and pressure, ensuring system efficiency and safety. According to a report by MarketsandMarkets, the global market for hydraulic components alone is anticipated to reach $22.4 billion by 2025, highlighting their indispensable role in manufacturing efficiency and automation.

Reservoirs store the hydraulic fluid and help dissipate heat, maintaining optimal operating conditions. The integration of smart technology into hydraulic systems further enhances their capabilities, allowing for real-time monitoring and predictive maintenance. As industries continue to evolve, the demand for efficient and reliable fluid power hydraulic systems will only intensify, reinforcing their significance in modern manufacturing.

Maintenance Tips for Optimizing Hydraulic Performance

Maintaining optimal performance in hydraulic systems is crucial for modern industrial operations. According to a report by the International Fluid Power Society, nearly 70% of hydraulic failures are attributed to inadequate maintenance. To minimize downtime and enhance efficiency, regular inspections and systematic maintenance routines should be implemented. This includes checking for leaks, inspecting hoses and fittings, and monitoring fluid levels and cleanliness, as fluid contamination can lead to significant performance degradation.

One effective maintenance tip is to adhere to a scheduled fluid analysis. By regularly testing the hydraulic fluid, operators can identify contaminants and wear particles that might compromise system integrity. A study conducted by the National Fluid Power Association highlights that adopting predictive maintenance strategies can reduce hydraulic maintenance costs by up to 25%. Additionally, ensuring that all components are calibrated correctly and operating within specified parameters can prevent premature failures and extend the lifespan of hydraulic equipment, ultimately leading to a more reliable and efficient industrial operation.

Future Trends in Hydraulic Technology for Modern Industry

The future of hydraulic technology in modern industry is poised for significant advancements, with an increasing emphasis on efficiency and sustainability. According to the International Fluid Power Society, the hydraulic industry is projected to grow at a compound annual growth rate (CAGR) of over 5.2% through 2025. This growth is driven by the rising demand for more efficient fluid power systems that can reduce operational costs and minimize energy consumption. Innovations in hydraulic machinery are also contributing to improved performance, reliability, and ease of maintenance, making them more attractive to manufacturers.

Another notable trend is the integration of smart technology and automation into hydraulic systems. As per the MarketsandMarkets report, the global smart hydraulic systems market is anticipated to reach $4.3 billion by 2027, reflecting a paradigm shift towards IoT-enabled devices. These developments not only enhance operational capabilities but also foster real-time monitoring and predictive maintenance, reducing downtime and maximizing resource efficiency. As industries adopt such technologies, the role of fluid power hydraulics becomes increasingly crucial, positioning them as essential components for achieving competitive advantage in the evolving industrial landscape.

Related Posts

-

5 Best Fluid Power Hydraulics Solutions for Optimal Performance

-

Ultimate Checklist for Global Buyers in Fluid Power Procurement

-

What Are the Key Components of Hydraulics Products and Their Applications

-

Essential Checklist for Selecting the Right Hydraulic Check Valves for Your Applications

-

How to Optimize Hydraulic Flow Control for Maximum Efficiency

-

Ultimate Guide to Mastering Hydraulic Flow Control Techniques for Optimal Performance

skip to Main Content

skip to Main Content