10 Essential Tips for Choosing Hydraulic Control Valves for Your Project?

When it comes to selecting hydraulic control valves, understanding the intricacies is crucial. Expert Tom Anderson, a veteran in the hydraulics industry, offers insight: "Choosing the right hydraulic control valves can make or break your project's success." This statement highlights the importance of informed decision-making in the selection process.

Hydraulic control valves govern fluid flow in various applications. They play a pivotal role in systems ranging from construction machinery to industrial equipment. A poor choice can lead to inefficient operation and costly repairs. With countless options available, the task may feel daunting. Delving deeper into the specifications of these valves is essential for effective project management.

Each project has unique demands. Not all hydraulic control valves will fit every scenario. Acquiring knowledge about flow rates, pressure ratings, and compatibility is vital. However, many overlook these details, which can lead to serious operational failures. Engaging with experts and conducting thorough research can help mitigate these risks.

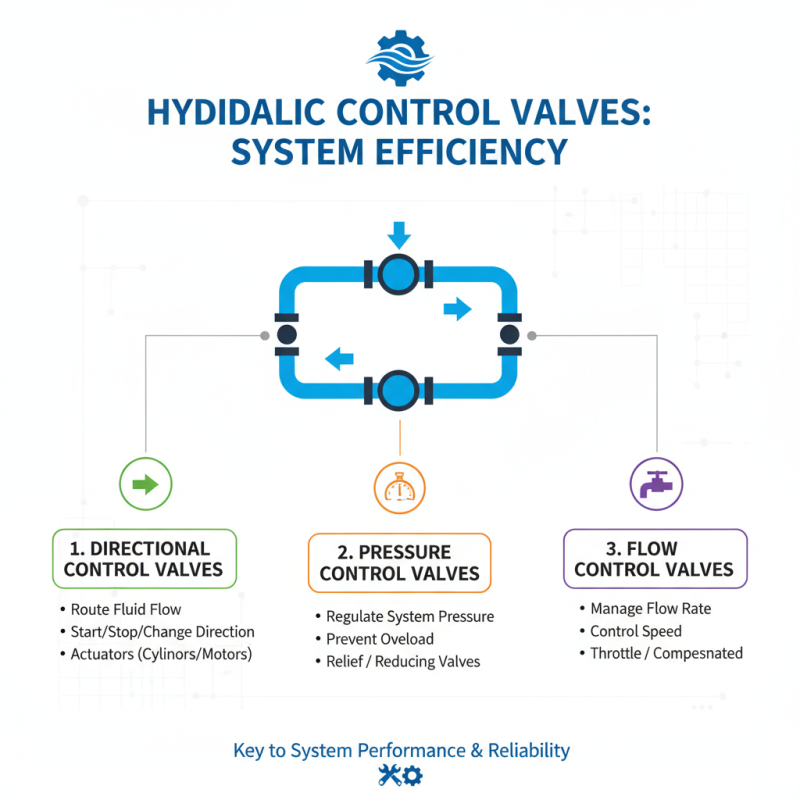

Understanding the Functionality of Hydraulic Control Valves

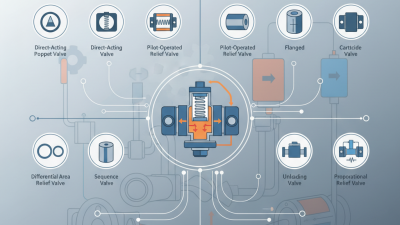

Hydraulic control valves play a crucial role in hydraulic systems. They manage fluid flow and pressure, ensuring system efficiency. A detailed understanding of how these valves function can greatly influence your project's success. These valves can be classified into various types, including directional, pressure, and flow control valves. Each type has its own specific application and understanding these can reduce operational issues.

When choosing hydraulic control valves, be aware of flow capacities. Some systems may require valves with higher flow capabilities. Selecting a valve that matches your system's specifications is key. Data shows that mismatched valves can lead to 20%-30% efficiency losses. Ensure to assess the required pressure ratings as well. This assessment can help avoid unexpected failures.

Tip: Verify compatibility with existing systems. An incompatible valve might lead to leaks or inefficiencies. Moreover, consider the materials used in the valve construction. Corrosion and wear can significantly impact performance. Evaluating environmental factors can help guide your selection process. Assessing the specific needs of your project will lead to better decision-making. In some cases, misjudgments can result in costly downtimes and repairs. Take time to study and evaluate all aspects before making a final choice.

Evaluating Project Requirements and Specifications

When selecting hydraulic control valves, evaluating project requirements is crucial. Start by understanding the application's specific needs. Consider factors such as pressure ratings and flow rates. Is your system complex? This will dictate the type of valve required.

Tip: Always assess the materials involved. Different fluids can corrode or damage certain valves. Ensure that your choices align with the medium being used.

Also, it's important to think about size and space limitations. Valves come in various dimensions. You might need to compromise on design preferences. Check the installation requirements before finalizing your selection.

Tip: Don't overlook the need for compatibility with existing systems. If your project integrates with other equipment, verify the connections and interfaces. Misalignment can cause serious issues later on.

Finally, be prepared for changes. Technical specifications may evolve during the project. Stay flexible, and adjust your valve choices as necessary. Reflect on your initial decisions throughout the process.

Assessing Compatibility with Fluid Types and Pressure Ratings

When selecting hydraulic control valves, assessing compatibility with fluid types and pressure ratings is crucial. Fluids vary in viscosity, temperature, and corrosiveness, which affects valve performance. For instance, a study by the Hydraulic Institute shows that using incompatible materials can lead to valve failure. This emphasizes the need for a thorough materials check.

Pressure ratings are equally important. A valve rated for 2000 psi should not be used in a 3000 psi system. Failing to match these ratings can result in catastrophic failure, as outlined in reports from the American Society of Mechanical Engineers. Many projects overlook this detail, leading to increased costs and safety risks.

It's essential to analyze how fluid properties interact with valve materials. Some fluids can cause erosion, especially in high-flow conditions. Regular assessments and fluid testing can help in adjusting specifications. Many engineers ignore these nuances, which can hinder long-term project success. Compatibility assessments should be part of the initial planning stages to prevent costly mistakes later.

10 Essential Tips for Choosing Hydraulic Control Valves for Your Project

| Tip | Description | Fluid Compatibility | Pressure Ratings |

|---|---|---|---|

| 1. Determine Fluid Type | Identify the type of fluid that will be used in the system. | Oil, Water, or Specialized Fluids | ≤ 3000 PSI |

| 2. Consider Temperature Limits | Evaluate the operating temperature of your hydraulic system. | -20°C to 80°C | Up to 3500 PSI |

| 3. Check Valve Size | Select the right valve size to match the flow requirements. | Compatible with various diameters | Max 4000 PSI |

| 4. Evaluate Flow Capacity | Ensure that the valve can handle the required flow rate without loss. | Fluid-specific | Up to 3000 PSI |

| 5. Assess Actuation Type | Decide between manual, electric, or pneumatic actuation. | All compatible types | Varies by model |

| 6. Review Leak Prevention Features | Check if the valve design minimizes leakage risks. | All fluids | ≤ 5000 PSI |

| 7. Analyze Materials Used | Ensure materials are suitable for the type of fluid. | Steel, Aluminum, Brass | Up to 6000 PSI |

| 8. Verify End Connections | Match the valve end connections to your piping system. | NPT, SAE, Flanged | Varies by type |

| 9. Choose Appropriate Seal Type | Select seals that can handle the fluid and pressure conditions. | Rubber, PTFE, Metal | Up to 5000 PSI |

| 10. Consult Manufacturer Specifications | Always refer to the manufacturer's guidelines for best practices. | Follow specific fluid compatibility charts | Confirm max pressure ratings |

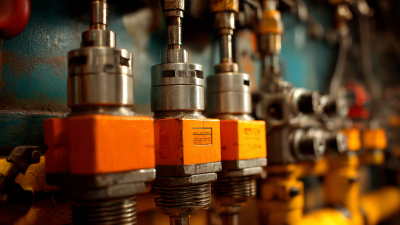

Identifying Valve Actuation Options and Control Methods

When selecting hydraulic control valves, understanding actuation options is crucial. Valves can be actuated manually or automatically. Manual actuators offer simplicity. However, they require more operator involvement. Automatic actuators can enhance efficiency but may introduce complexity. Think about your project’s specific needs.

Consider pressure and flow requirements. Different actuation methods provide various advantages. Electric and pneumatic actuators respond quickly. They enhance precision in control. On the other hand, hydraulic actuators can deliver higher force. Assess which method fits best for your system.

One important tip is to evaluate installation and maintenance. Some valves may be easy to install, while others may require specialized knowledge. Inspect the access to valve locations; sometimes, they are in tight spaces. Maintenance might be a burden if parts are hard to reach. Never overlook this aspect. A poor decision here can lead to future headaches.

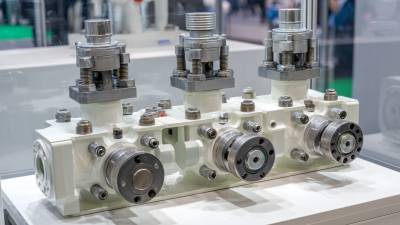

Hydraulic Control Valve Selection Criteria

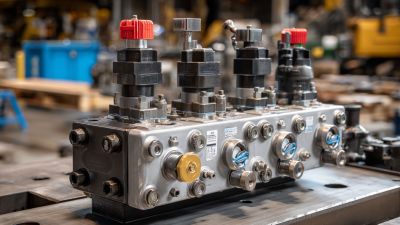

Analyzing Manufacturer Reputation and Product Support Services

When selecting hydraulic control valves, manufacturer reputation plays a crucial role. A well-regarded manufacturer is likely to offer quality products and reliable support services. Look for reviews and case studies to understand their track record. It’s vital to assess their customer service responsiveness. Poor support can complicate troubleshooting.

Understanding support services is essential too. Check if the manufacturer provides installation assistance and training. Some offer online resources, which can be quite beneficial. These resources help you understand the product better. Don’t overlook warranty offerings; they indicate the manufacturer's confidence in their products.

When choosing a valve, consider compatibility with your existing systems. Analyze the specifications carefully. Don’t rush through comparisons. Address concerns about performance early on. Many buyers regret overlooking this aspect. Take your time to ensure the decision fits your project needs. Investing effort here pays off in efficiency and safety.

Related Posts

-

Exploring the Future of Hydraulic Control Valves at the 2025 China Import and Export Fair

-

7 Essential Tips for Choosing Hydraulic Flow Control Valves for Your Business

-

Unlocking Efficiency: How Hydraulic Directional Control Valves Boost Industrial Performance by 30%

-

How to Choose the Right Hydraulic Valves for Your Industrial Needs

-

Understanding the Essential Role of Continental Hydraulic Valves in Modern Industry

-

Top 10 Hydraulic Pressure Relief Valves for Optimal Equipment Performance

skip to Main Content

skip to Main Content