How to Choose the Right Hydraulic Check Valve for Your System

Choosing the right hydraulic check valves for your system is a crucial decision that can significantly impact efficiency and performance. Hydraulic check valves play a vital role in controlling the flow of fluids, preventing backflow, and ensuring the safety of hydraulic systems.

With a wide variety of options available in terms of size, material, and design, it can be daunting to determine which type is best suited for your specific application. Factors such as pressure ratings, flow rates, and environmental conditions must be carefully considered to ensure optimal functionality.

In this guide, we will explore essential criteria and practical tips to help you navigate the selection process, ensuring that the hydraulic check valves you choose contribute to the overall reliability and effectiveness of your hydraulic system.

Understanding the Basics of Hydraulic Check Valves and Their Functionality

Hydraulic check valves play a crucial role in fluid systems, ensuring that hydraulic fluid flows in one direction while preventing backflow. These valves are designed to automatically open and close based on the pressure from the flowing fluid. Understanding their functionality is essential for selecting the right check valve for your hydraulic system. A basic grasp of how these devices operate can help in avoiding potential system failures and maintaining efficiency.

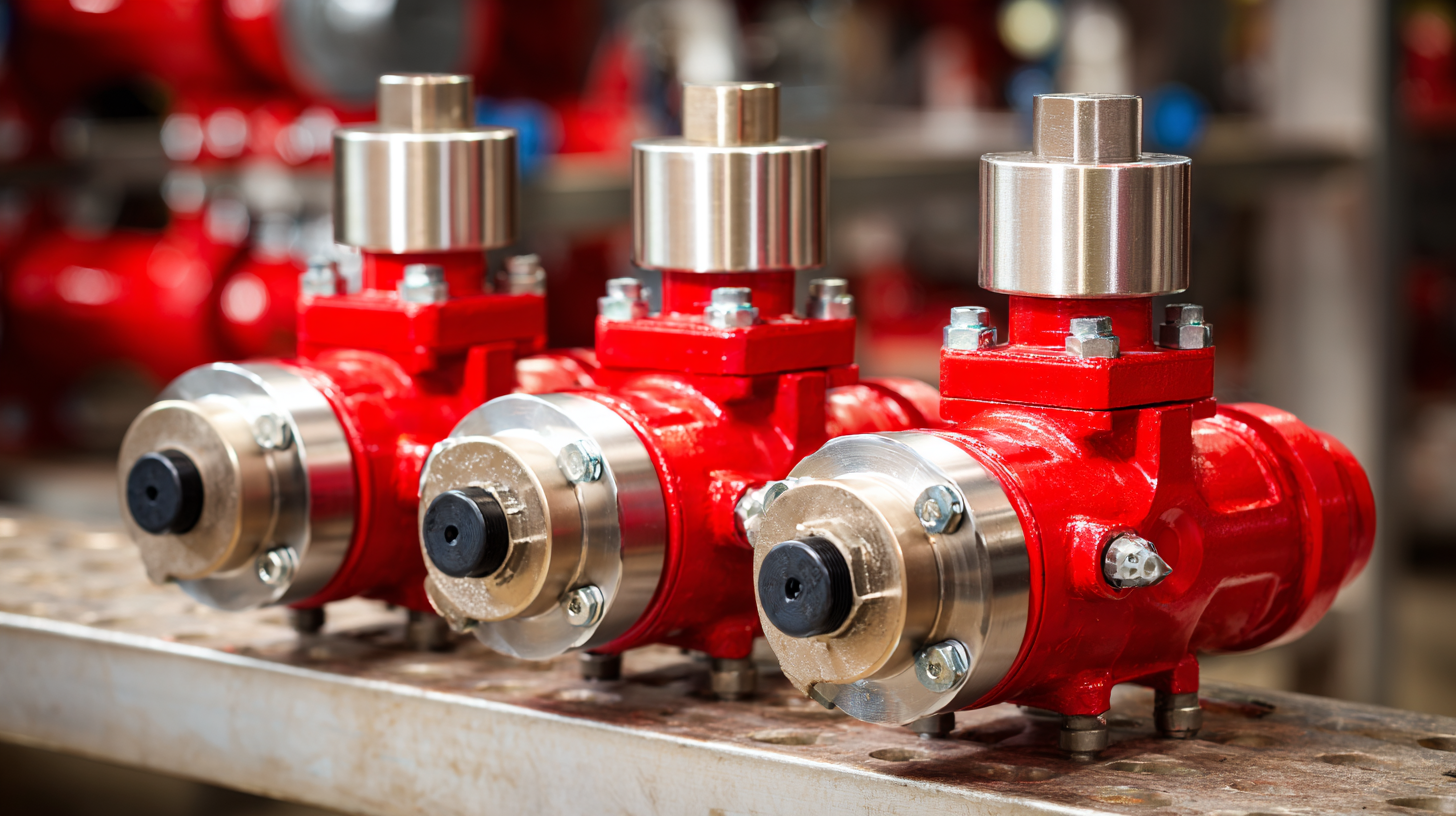

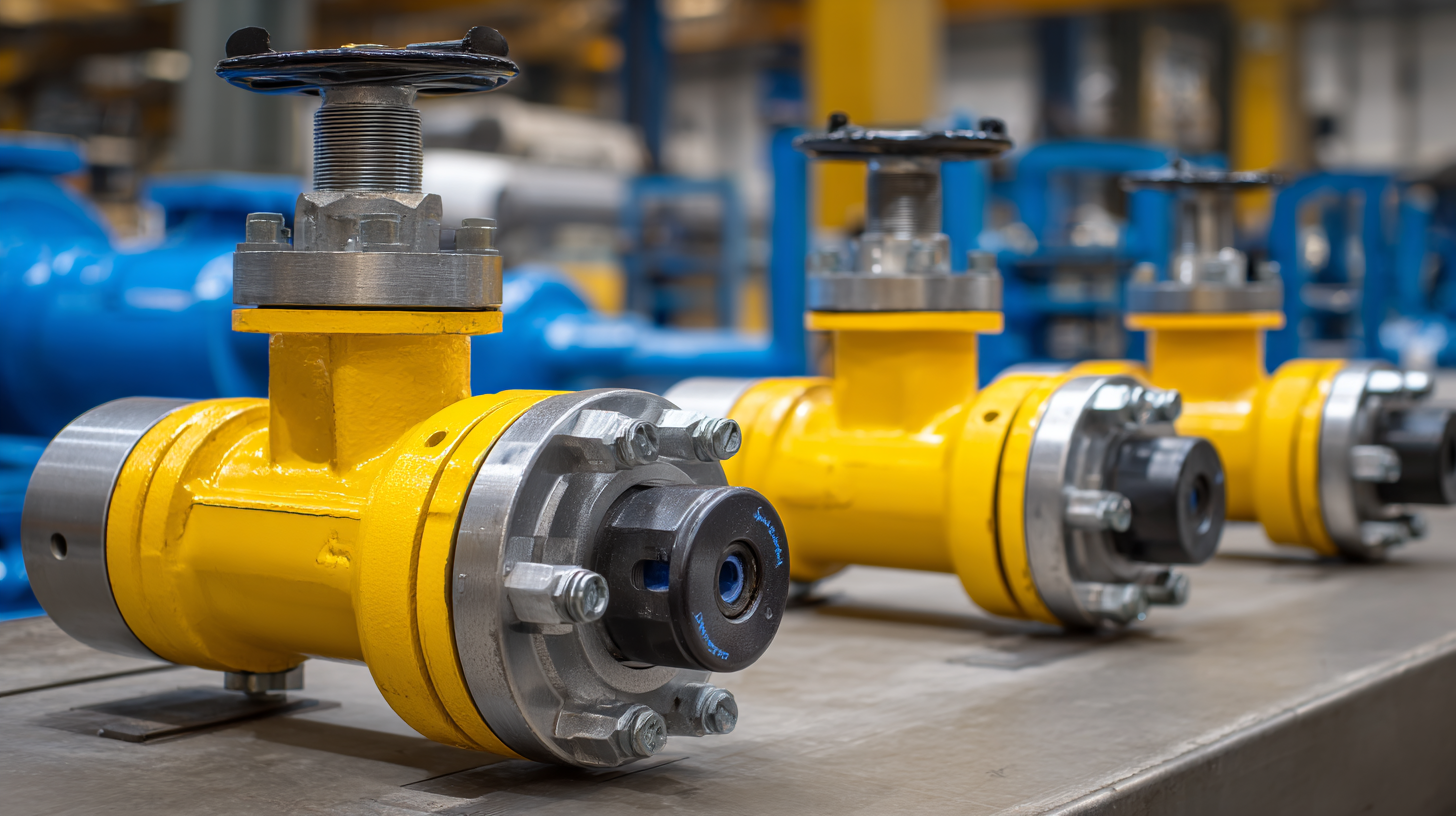

There are several types of hydraulic check valves, including ball, piston, and diaphragm types, each suited for different applications. Selecting the right valve involves considering factors like flow rate, pressure ratings, and fluid types present in your system. Additionally, the physical size and installation requirements must align with your system's layout. By familiarizing yourself with these fundamentals, you can make an informed decision that enhances the reliability and effectiveness of your hydraulic operations.

Identifying Different Types of Hydraulic Check Valves Available in the Market

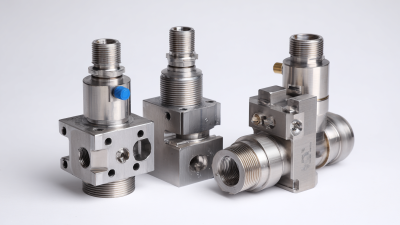

When selecting the right hydraulic check valve for your system, it's essential to understand the variety of options available on the market. Check valves come in different designs, including ball, gate, and diaphragm types, each suited for specific applications in hydraulic systems. The choice often depends on factors such as flow direction, pressure ratings, and the compatibility with different fluid types, including liquid and gas. Recent trends show a growing demand for space-saving solutions, prompting manufacturers to introduce compact versions of traditional check valves that maintain efficiency while occupying less space.

Moreover, advancements in hydraulic control technology have led to the development of more precise hydraulic check valves, enhancing the overall performance of mechanical systems. These innovations include electro-hydraulic designs that optimize operation, catering to the needs of modern mobile machinery. Additionally, tools like thread ID kits are invaluable in ensuring compatibility with various hydraulic fittings, making the selection process smoother for users. Understanding these aspects will enable you to identify the most suitable check valve for your specific hydraulic application.

Evaluating Key Specifications and Features for Your Hydraulic System

When selecting the appropriate hydraulic check valve for your system, it's essential to evaluate various key specifications and features that can significantly impact performance and reliability. According to a report by the International Hydraulic Association, nearly 30% of hydraulic system failures are attributed to improper valve selection. Understanding parameters such as flow rate, pressure rating, and material compatibility can help prevent these costly downtime situations. Ideally, the flow rate should match your system's operational requirements, while the pressure rating must exceed the maximum expected operational pressure to ensure safety and performance.

Additionally, consider the type of hydraulic fluid used in your system. A study published by the Hydraulic Engineering Society highlights that choosing a valve material compatible with your specific fluid can enhance durability and longevity. For example, valves made from stainless steel or specific polymer materials are known to withstand corrosive fluids better than their standard counterparts. Furthermore, the orientation of the valve, whether horizontal or vertical, may also influence its performance, as certain designs are more adept at handling varying gravitational forces and flow dynamics. Selecting the right valve based on these specifications not only optimizes system efficiency but also contributes to lower maintenance costs and increased overall reliability.

How to Choose the Right Hydraulic Check Valve for Your System - Evaluating Key Specifications and Features for Your Hydraulic System

| Specification | Value | Description |

|---|---|---|

| Body Material | Steel / Aluminum / Brass | Material suitability based on application and fluid type. |

| Pressure Rating | Up to 6000 psi | Maximum pressure the valve can withstand. |

| Size | 1/4" to 2" | Available diameters to match system requirements. |

| Temperature Range | -20°F to 250°F | Operating temperature limits for effective operation. |

| Flow Direction | Uni-directional | Direction in which fluid is permitted to flow. |

| Seal Material | Nitrile / Viton | Material resistance to fluid and temperature exposure. |

| Actuation Type | Spring-loaded / Pilot-operated | Mechanism used to open and close the valve. |

| Applications | Industrial / Mobile Equipment | Suitable applications for the valve under consideration. |

Assessing Compatibility with Existing Equipment and System Requirements

When selecting a hydraulic check valve, assessing compatibility with existing equipment and system requirements is critical to ensure functionality and efficiency. Begin by reviewing the specifications of your current hydraulic system, including pressure ratings, flow rates, and the types of fluid used. The chosen check valve must match these parameters to prevent failures or inefficiencies that could disrupt operations. Additionally, consider the materials of both the valve and surrounding components to avoid corrosion or wear that could result from incompatible materials.

Another vital aspect to consider is the installation space and configuration of your existing system. Ensure that the dimensions of the hydraulic check valve fit within the available space and can be easily integrated without requiring extensive modifications. It’s also beneficial to evaluate the operational conditions such as temperature ranges and shock loads the valve will be subjected to, as these factors significantly influence the performance and longevity of the component. By carefully assessing these elements, you can select a hydraulic check valve that not only complements your system but also enhances its overall performance.

Maintaining and Troubleshooting Your Hydraulic Check Valve for Optimal Performance

Maintaining and troubleshooting your hydraulic check valve is crucial for ensuring optimal performance in your hydraulic system. Regular inspections should be performed to identify any signs of wear and tear or possible leakage. This includes checking for unusual noises during operation, which might indicate that the valve is not seating properly. Keeping the valve clean and free of debris will also help maintain its functionality, as contaminants can lead to blockages and prevent the valve from opening or closing correctly.

Maintaining and troubleshooting your hydraulic check valve is crucial for ensuring optimal performance in your hydraulic system. Regular inspections should be performed to identify any signs of wear and tear or possible leakage. This includes checking for unusual noises during operation, which might indicate that the valve is not seating properly. Keeping the valve clean and free of debris will also help maintain its functionality, as contaminants can lead to blockages and prevent the valve from opening or closing correctly.

In cases where you encounter performance issues, troubleshooting is key. Start by verifying the valve's orientation; an incorrectly installed check valve can lead to backflow problems. If the valve is functioning inconsistently, consider checking the hydraulic fluid for contamination and ensure that the pressure settings are within the manufacturer’s specifications. Additionally, it may be beneficial to replace any worn seals or gaskets that could compromise the valve’s integrity. By proactively addressing maintenance and troubleshooting, you can extend the life of your hydraulic check valve and improve the overall efficiency of your hydraulic system.

Related Posts

-

Addressing Common Hydraulic Flow Control Challenges: Insights and Data from Industry Experts

-

Ultimate Guide to Understanding Check Valves and Their Applications

-

How to Select the Right Hydraulic Pressure Relief Valve for Your System Needs

-

10 Tips for Choosing the Right Flow Valves for Your Business Needs

-

Essential Checklist for Selecting the Right Hydraulic Check Valves for Your Applications

-

7 Essential Tips for Maximizing the Life of Your Continental Hydraulic Pump

skip to Main Content

skip to Main Content