How to Choose the Right Continental Hydraulic Valves for Your System?

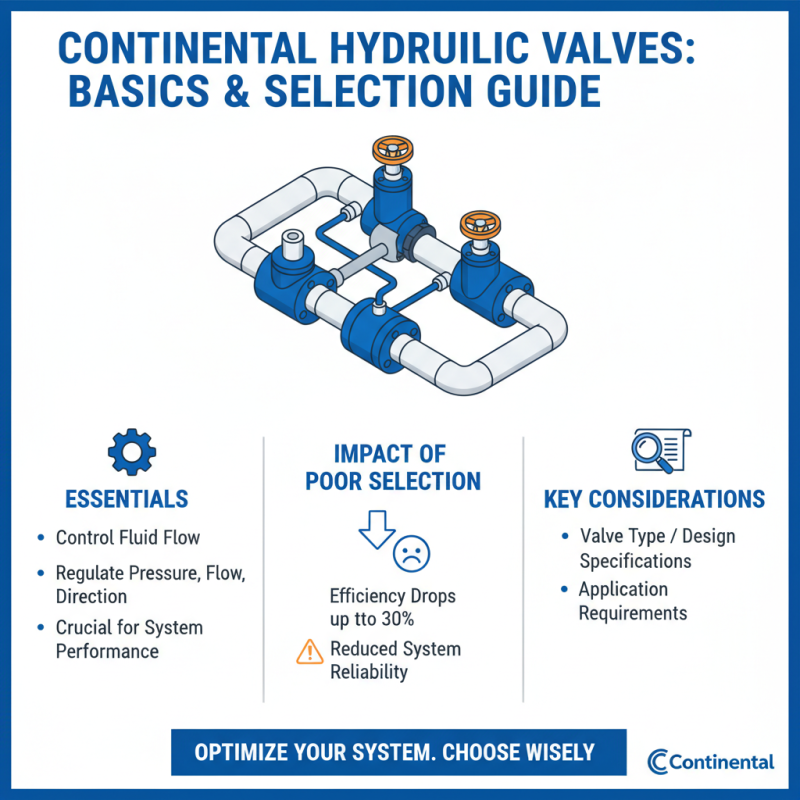

Choosing the right continental hydraulic valves for your system can be a daunting task. These valves play a crucial role in hydraulic systems, controlling fluid flow and pressure. Understanding their various specifications is essential.

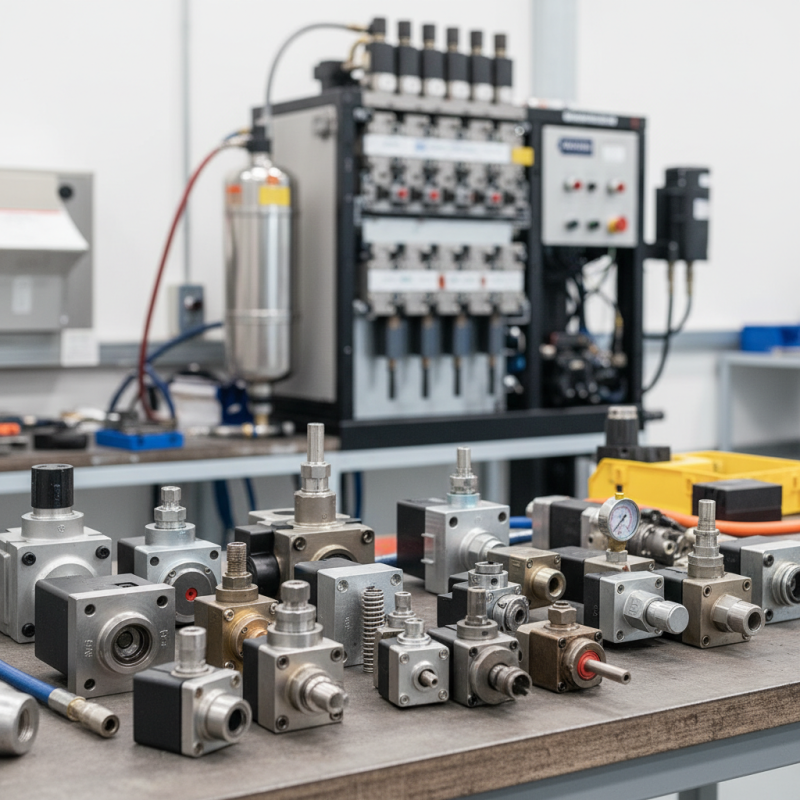

Continental hydraulic valves come in many shapes and sizes. Each type serves different functions. You need to consider your system's requirements. For example, the pressure ratings and flow capacities vary widely across models. This can affect system performance significantly.

It’s also important to reflect on the specific applications. Compatibility with existing components is essential. You might find that a popular valve type doesn’t meet all of your needs. Thus, take your time to review all options carefully. Ignoring these factors can lead to inefficiencies and costly repairs. Remember, a well-chosen valve enhances performance, but a poor choice can lead to frustrating issues.

Understanding the Basics of Continental Hydraulic Valves

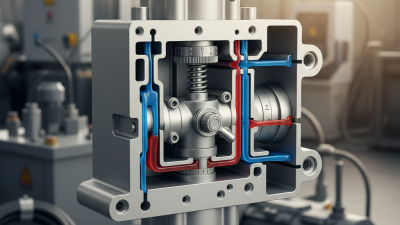

When choosing hydraulic valves, understanding the basics is essential. Continental hydraulic valves play a crucial role in controlling fluid flow. Their design and functionality can significantly impact your system's performance. These valves regulate pressure, flow rate, and direction, ensuring efficient operation. According to industry reports, poorly selected valves can lead to efficiency drops of up to 30%. Therefore, knowing the specifications and applications of various valve types is vital.

Tip: Consider the application environment. Factors like temperature, fluid type, and pressure ratings are critical. For instance, valves used in high-pressure systems must be durable and resistant to wear. Evaluate your system's requirements closely. A mismatch can lead to catastrophic failures or increased maintenance costs.

Additionally, look at the flow characteristics of the valves. The flow coefficient (Cv) is a key metric. It measures the valve's capacity to allow fluid movement. Reports indicate that valves with a higher Cv generally offer better performance. However, more doesn't always mean better. Oversizing valves can create turbulence and pressure drops. Balancing size and performance is crucial for optimal operation.

Evaluating the Specifications of Your Hydraulic System

When evaluating the specifications of your hydraulic system, start by understanding your specific needs. This involves assessing the flow rate and pressure requirements. Each component in your system plays a crucial role. The right valve will ensure smooth operation.

Consider the type of fluids your system uses. Different fluids can affect valve materials. Compatibility is key in preventing leaks or failures. It's also important to think about the environment where your system operates. Extreme temperatures or contamination can impact performance.

You may realize that your calculations may not always match the real-world demands. Sometimes valves can be over-engineered or chosen based on assumptions, leading to inefficiencies. Testing and feedback are invaluable for refining your choices. Collecting data from actual operations can guide necessary adjustments. Rethinking these aspects may help improve your system's overall efficiency.

Identifying the Types of Continental Hydraulic Valves Available

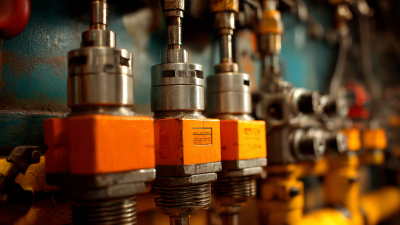

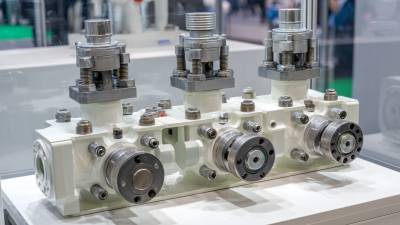

When selecting hydraulic valves, understanding the types available is crucial. Continental hydraulic valves come in various types, including directional control valves, pressure control valves, and flow control valves. Each type serves specific functions within hydraulic systems. Directional control valves, for instance, manage the flow direction. They ensure that hydraulic fluid moves efficiently through the system.

Pressure control valves regulate the pressure within hydraulic systems. They can prevent overpressure, which might lead to catastrophic failures. Flow control valves allow for the adjustment of flow rates, enabling precise control over hydraulic operations. According to industry reports, improper valve selection can lead to efficiency losses of around 30%. This is a significant concern for system performance.

Choosing the right type of valve requires consideration of several factors. These include the application's pressure requirements, flow rates, and the environment in which the system operates. Often, engineers overlook small design details, leading to issues in performance. For example, unsuitable materials for the working environment can cause premature wear. Careful analysis can prevent costly mistakes and enhance system longevity.

How to Choose the Right Continental Hydraulic Valves for Your System?

| Type of Hydraulic Valve | Functionality | Typical Applications | Pressure Rating | Size Range |

|---|---|---|---|---|

| Directional Control Valves | Control the direction of fluid flow | Excavators, Forklifts | Up to 350 bar | 1/4" to 2" |

| Pressure Control Valves | Regulate system pressure | Hydraulic Presses, Injection Molding | Up to 400 bar | 1/4" to 3" |

| Flow Control Valves | Regulate the flow rate | Mobile Machinery, Agricultural Equipment | Up to 300 bar | 1/4" to 2" |

| Check Valves | Prevent backflow of fluid | Hydraulic Circuits, Aerospace | Up to 350 bar | 1/4" to 4" |

| Relief Valves | Prevent overpressure in the system | Industrial Applications, Automation | Up to 350 bar | 1/4" to 2" |

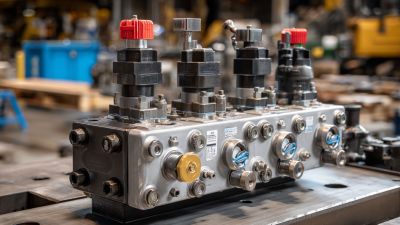

Considering Factors for Selecting the Right Valve Size and Type

Choosing the right hydraulic valve for your system involves several important factors. One major aspect is the size of the valve. Too small, and you risk pressure drops and flow restriction. Too large, and the response time may be slow. It’s essential to measure the system’s flow rate accurately. Use precise data to determine the required valve size.

Another critical factor is the type of valve. Various designs serve different purposes. Consider the system's pressure, temperature, and fluid type. Each application has unique requirements, which means a one-size-fits-all approach rarely works. Occasionally, you may find yourself stuck in choice paralysis. Analyzing the specific system needs and consulting manual guidelines can help clarify your options.

Lastly, installation and maintenance should not be overlooked. The complexity of the valve design can affect accessibility. Some valves require more frequent maintenance. Balancing performance and ease of maintenance is crucial. A valve that performs well may be challenging to service, leading to downtime. Each decision requires careful consideration, as mistakes can be costly.

Choosing the Right Continental Hydraulic Valves: Size and Type Analysis

Maintenance and Troubleshooting Tips for Hydraulic Valves

Maintaining hydraulic valves is crucial for optimal system performance. Regular checks can prevent costly failures. Start by inspecting for leaks, as even minor drips can indicate larger issues. Look at seals and connections closely. Are they worn or damaged? Replacing them promptly can save time and money down the line.

Adjusting valve settings is another essential task. Over time, they may drift from their original calibration. Testing pressure and flow rates regularly ensures everything operates within required specifications. If something feels off, don’t hesitate. Delve deeper to identify the root cause. Sometimes the simplest fixes yield the best results, like clearing debris from a valve.

Troubleshooting is part of the process. Unresponsive valves can create chaos. In these moments, assess the control signals. Are they intact? If not, it might be an electrical issue. Keep a log of each maintenance activity. This will help track improvements or recurring problems. Creating a habit of detailed documentation can enhance overall system reliability.

Related Posts

-

Unlocking Efficiency: How Hydraulic Directional Control Valves Boost Industrial Performance by 30%

-

How to Choose the Right Hydraulic Valves for Your Industrial Needs

-

How to Choose the Right Hydraulic Check Valve for Your System

-

Understanding the Essential Role of Continental Hydraulic Valves in Modern Industry

-

Why Hydraulic Flow Control Valves Are Essential for Optimal Machinery Performance

-

Exploring the Future of Hydraulic Control Valves at the 2025 China Import and Export Fair

skip to Main Content

skip to Main Content