How to Choose the Right Hydraulic Valves for Your Industrial Needs

In industrial applications, selecting the appropriate hydraulic valves is crucial for optimizing system performance and ensuring operational efficiency. Hydraulic valves play a vital role in controlling the flow and pressure within hydraulic systems, which are integral to various sectors, including manufacturing, construction, and mining.

According to a market analysis by Research and Markets, the global hydraulic valves market is projected to reach $12.5 billion by 2025, growing at a CAGR of 5.3%. This growth highlights the increasing demand for advanced hydraulic solutions that can handle more complex applications. However, with numerous options available, it is essential to understand the types of hydraulic valves and their specific functionalities to meet diverse industrial needs effectively.

Proper selection not only enhances productivity but also significantly reduces maintenance costs and downtime, making it a key factor for industrial success.

Understanding the Functions and Types of Hydraulic Valves

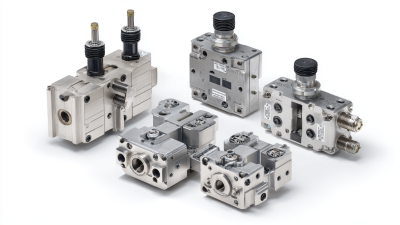

Hydraulic valves are crucial components in various industrial applications, serving to control the flow and pressure within hydraulic systems. Understanding their functions and types is essential for selecting the right valve for specific needs. The primary functions of hydraulic valves include directing, stopping, or regulating the flow of hydraulic fluid. Directional control valves manage the route of the fluid, while pressure relief valves safeguard the system from excess pressure by releasing fluid when necessary. Flow control valves, on the other hand, adjust the speed of actuators by regulating the flow rate.

There are several types of hydraulic valves to consider, each tailored to different operational requirements. Common types include spool valves, ball valves, and check valves. Spool valves are versatile and can manage multiple flow paths, making them ideal for complex systems. Ball valves provide a quick on/off capability with minimal pressure drop, suited for applications requiring high flow rates. Check valves allow fluid flow in one direction only, protecting equipment from backflow. By understanding these functionalities and types, industries can make informed decisions, ensuring efficiency and reliability in their hydraulic systems.

Comparison of Different Types of Hydraulic Valves

Assessing Your Industrial Application Requirements

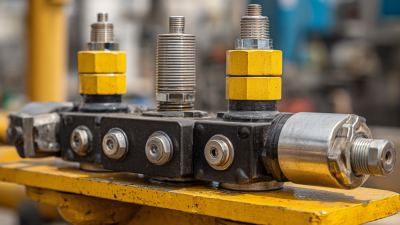

When selecting hydraulic valves for industrial applications, it's crucial to first assess the specific requirements of the application. According to a report from the Hydraulic Institute, approximately 70% of hydraulic system failures stem from improper valve selection. This highlights the significance of understanding system pressure, flow rates, and the medium being controlled. For instance, high-pressure applications typically require valves made from robust materials such as stainless steel, while lower pressure systems can use more cost-effective options like aluminum or polymer.

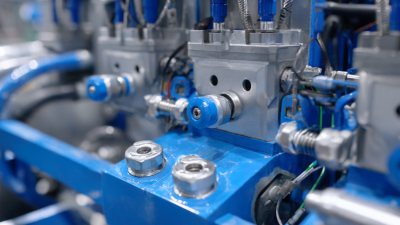

Moreover, the operational environment plays a significant role in valve selection. An analysis by the International Fluid Power Society emphasizes the necessity of considering factors like temperature extremes, potential exposure to corrosive substances, and any vibration or shock that might affect valve performance. By properly evaluating these parameters, engineers can ensure the chosen hydraulic valves not only meet performance standards but also enhance the overall efficiency and reliability of the hydraulic system. This strategic approach mitigates risks and aligns with industry best practices, ultimately leading to more sustainable and cost-effective operations.

Evaluating Flow Rates, Pressure Ratings, and Compatibility

When selecting hydraulic valves for your industrial applications, evaluating flow rates is crucial. Flow rate, measured in liters per minute (LPM) or gallons per minute (GPM), determines how quickly fluid can move through the system. It's essential to match the flow rate of your hydraulic valve with the requirements of your machinery to ensure optimal performance. A valve with too low a flow rate may restrict operations, leading to inefficiency, while one with too high a rate could overwhelm the system and cause damage.

In addition to flow rates, pressure ratings must also be considered. Hydraulic systems operate under varying pressures, and selecting a valve with a suitable pressure rating is vital to prevent malfunction or failure. The valve should be able to handle both the maximum operating pressure and any potential pressure spikes. Furthermore, compatibility with the hydraulic fluid used in your system is necessary to avoid chemical reactions that could compromise the system's integrity. Ensuring that the valve materials are resistant to the specific fluid will enhance durability and prevent leaks or breakdowns.

How to Choose the Right Hydraulic Valves for Your Industrial Needs

| Valve Type | Flow Rate (GPM) | Pressure Rating (PSI) | Port Size (inches) | Material Compatibility |

|---|---|---|---|---|

| Directional Control Valve | 20 | 3000 | 1/2 | Steel, Aluminum |

| Pressure Relief Valve | 15 | 4000 | 3/8 | Brass, Stainless Steel |

| Flow Control Valve | 25 | 2500 | 3/4 | Polymer, Aluminum |

| Check Valve | 10 | 3000 | 1/4 | Steel, Composite |

| Solenoid Valve | 30 | 1500 | 1 | Nylon, Aluminum |

Choosing Between Manual and Automatic Hydraulic Valves

When choosing between manual and automatic hydraulic valves for your industrial needs, it’s essential to understand the specific application requirements. Manual valves offer direct control, allowing operators to adjust flows precisely, which can be advantageous in situations that necessitate frequent adjustments. According to industry reports, manual valves are often favored in smaller operations where simplicity and cost-effectiveness are critical factors.

When choosing between manual and automatic hydraulic valves for your industrial needs, it’s essential to understand the specific application requirements. Manual valves offer direct control, allowing operators to adjust flows precisely, which can be advantageous in situations that necessitate frequent adjustments. According to industry reports, manual valves are often favored in smaller operations where simplicity and cost-effectiveness are critical factors.

On the other hand, automatic hydraulic valves excel in environments that demand speed and efficiency, akin to the meticulous engineering of high-performance sports cars. These valves can significantly reduce response times and mitigate human error, allowing systems to operate at optimal levels. A study revealed that integrating automatic valves can enhance system performance by up to 30%, providing faster reaction times in dynamic applications.

Tips: When deciding on the right valve type, consider the operational environment and the desired level of control. For high-frequency tasks, automatic valves may provide better efficiency, while manual valves might suffice for low-volume, precision-based needs. Additionally, evaluate maintenance requirements, as automatic systems may demand more sophisticated upkeep compared to their manual counterparts.

Maintenance and Longevity Considerations for Hydraulic Valves

When selecting hydraulic valves for industrial applications, maintenance and longevity are crucial factors that cannot be overlooked. The complexity of hydraulic systems means that contaminants like dirt and moisture can significantly reduce the operational life of valves. Therefore, ensuring systems cleanliness is vital. Preventative maintenance plans are your first line of defense; they should be designed to minimize the intrusion of impurities and thereby extend the lifespan of hydraulic components.

Tips: Regularly inspect and clean hydraulic systems to prevent wear and tear caused by contaminated fluids. Implementing advanced monitoring technologies can also provide insights into maintenance needs, enabling a shift from reactive to proactive maintenance strategies. This approach not only ensures that you’re up-to-date on critical maintenance intervals but also helps avert costly failures.

Moreover, as the industry evolves, keeping abreast of trends in hydraulic fluid formulations can significantly impact the performance and longevity of hydraulic valves. Innovations may lead to more durable and effective fluids that resist degradation, thus prolonging the life of your hydraulic systems. Maintaining an open dialogue with suppliers about the latest advancements can further aid in ensuring that your systems remain efficient and reliable.

Related Posts

-

7 Essential Tips for Choosing Hydraulic Flow Control Valves for Your Business

-

How to Optimize Hydraulic Flow Control Valves for Maximum Efficiency

-

How to Optimize Hydraulic Flow Control for Maximum Efficiency

-

How to Choose the Right Hydraulic Pressure Relief Valve for Your Application

-

How to Choose the Right Hydraulic Check Valve for Your System

-

10 Tips for Choosing the Right Flow Valves for Your Business Needs

skip to Main Content

skip to Main Content