2025 How to Choose the Best Control Valves for Your Industrial Applications with Expert Insights

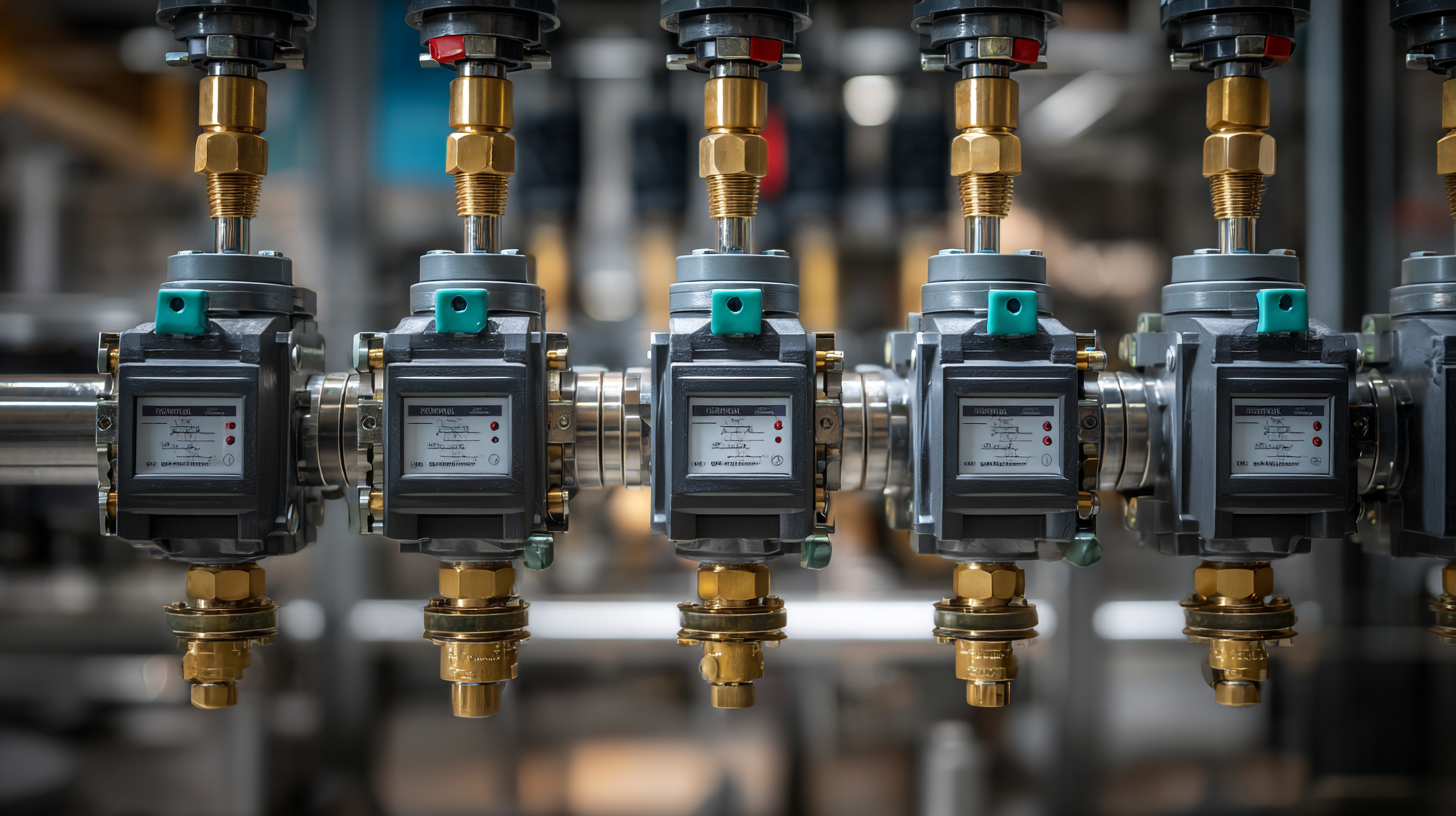

In the world of industrial applications, the selection of appropriate control valves is pivotal to ensuring optimal process efficiency and reliability. As industry expert Dr. Emily Richardson, a leading authority in fluid dynamics, emphasizes, "Choosing the right control valves is not just a matter of functionality; it's about integrating performance with the unique demands of the system." This insight highlights the necessity of a thorough understanding of both the technical specifications and the operational environment when selecting control valves.

The right control valves can significantly enhance system responsiveness and maintain precise control over flow rates, pressures, and temperatures. Whether it’s for chemical processing, water treatment, or HVAC applications, the selection process must consider various factors such as material compatibility, operating conditions, and actuator types. By following expert advice and understanding the specific requirements of their applications, engineers can make informed choices that lead to improved performance and reduced maintenance costs.

This article will delve into the top 5 factors to consider when selecting control valves, providing insights from industry experts and case studies that illustrate best practices in valve selection. As we explore these essential aspects, readers will gain a clearer perspective on how to navigate the complexities of control valves and ultimately optimize their industrial operations.

Understanding the Importance of Control Valves in Industrial Applications

Control valves play a crucial role in various industrial applications by regulating the flow, pressure, and temperature of fluids within a system. They act as the frontline defense in maintaining operational efficiency and safety. When properly selected and configured, control valves ensure that processes run smoothly, avoiding costly downtimes and potential hazards. The ability of these valves to respond to changes in system conditions influences not just performance but also energy consumption, underscoring their significance in achieving operational excellence.

In addition to efficiency, control valves contribute to the overall safety of industrial operations. By maintaining desired set points and preventing overpressure situations, they protect both equipment and personnel. With rigorous standards governing industrial processes, the importance of choosing the right control valve cannot be overstated. Expert insights into valve types, materials, and configurations enable industries to make informed decisions that enhance reliability and minimize risks. Selecting a control valve that is tailored to specific application requirements is thus essential for optimizing functionality and ensuring long-term success in industrial settings.

Key Factors to Consider When Selecting Control Valves

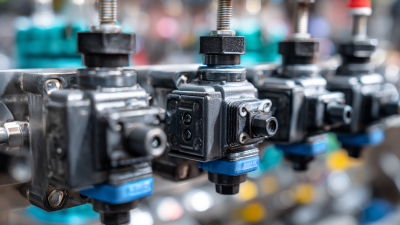

When choosing control valves for industrial applications, particularly in the pharmaceutical industry, several key factors must be considered to ensure optimal performance and safety. One of the most critical aspects is the type of valve best suited for specific applications, with diaphragm valves gaining popularity for their ability to minimize contamination and provide reliable service. According to industry reports, the value of diaphragm valves used in pharmaceutical processes is projected to grow from $123.3 million in 2024 to $284.6 million by 2032, reflecting a compound annual growth rate (CAGR) of 11.02%. This significant growth underscores the increasing reliance on high-quality control valves in meeting stringent regulatory standards and manufacturing efficiency.

Another essential factor is the valve material, which must be compatible with the media being controlled to prevent chemical reactions that could compromise the process. Material selection affects not just the longevity and reliability of the valve but also maintenance needs and overall system costs. Additionally, the valve's sizing and flow characteristics play a crucial role in ensuring that the desired flow rate and pressure drop are maintained within application parameters. Taking the time to analyze these factors using expert insights and industry data can significantly enhance operational success and ensure compliance with industry regulations.

expert Insights on Different Control Valve Types and Their Uses

When selecting control valves for industrial applications, it's crucial to understand the diverse types of valves available and their specific uses. According to industry insights, control valves serve essential roles in regulating flow, pressure, and temperature in various processes. Each type, from globe valves for precise flow control to ball valves for quick shut-off, has unique performance characteristics that can significantly affect operational efficiency. The Global Motor Starters market, poised to reach USD 12.8 billion by 2034 with a CAGR of 5.8%, indicates a robust growth trend in motor control technologies, which includes the integration of advanced control valves in energy management systems.

The effective management of control valve performance is increasingly reliant on data analytics and AI technologies. Processing plants can leverage historical data to make informed decisions regarding the maintenance and selection of control valves, enhancing their operational efficiency. As noted in recent market research, the adoption of AI not only optimizes valve performance but also improves overall plant performance, ensuring safety and compliance in industrial operations. Understanding the specific requirements of your system and matching them with the right valve types will drive better process outcomes and contribute to sustained growth in the industrial sector.

Common Mistakes to Avoid When Choosing Control Valves

When selecting control valves for industrial applications, avoiding common mistakes is crucial to ensuring system efficiency and reliability. One frequent error is overlooking the specific requirements of the application, such as flow rates, pressure drops, and the nature of the fluid being controlled. Professionals often make the assumption that a one-size-fits-all approach works, but each application has unique characteristics that must be taken into account. Failing to analyze these factors can lead to insufficient valve performance, resulting in costly downtime and maintenance issues.

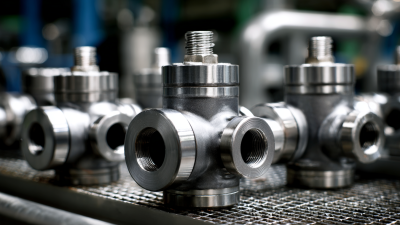

Another mistake is neglecting to consider the compatibility of the valve materials with the process media. Selecting a valve made from unsuitable materials can lead to corrosion, leaks, and ultimately system failure. It is essential to analyze the chemical and thermal properties of the fluids involved and choose materials that will withstand the operational conditions. Additionally, underestimating the importance of valve sizing can also impact performance; incorrectly sized valves can cause turbulence and even damage downstream equipment. By paying attention to these common pitfalls, industries can enhance their control systems and avoid unintended consequences.

2025 How to Choose the Best Control Valves for Your Industrial Applications with Expert Insights - Common Mistakes to Avoid When Choosing Control Valves

| Valve Type | Application | Size Range (inches) | Typical Materials | Common Mistakes |

|---|---|---|---|---|

| Globe Valve | Flow Regulation | 0.5 - 24 | Stainless Steel, Carbon Steel | Ignoring Pressure Drop Calculations |

| Ball Valve | On/Off Control | 0.5 - 12 | PVC, Brass, Stainless Steel | Choosing Based on Size Alone |

| Butterfly Valve | Flow Isolation | 2 - 60 | Cast Iron, Stainless Steel | Overlooking Leakage Rates |

| Check Valve | Preventing Backflow | 1 - 24 | Brass, Stainless Steel | Not Considering Flow Direction |

| Diaphragm Valve | Corrosive Liquids | 0.5 - 10 | PTFE, Rubber | Neglecting Temperature Limits |

Future Trends in Control Valve Technologies for Industrial Use

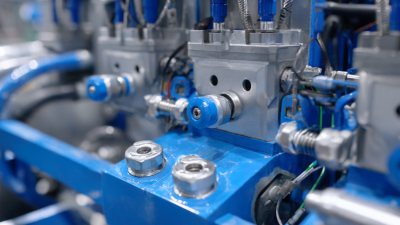

As the industrial landscape evolves, control valve technologies are witnessing significant advancements that promise to shape the future of various applications. According to recent market trends, the control valve sector is projected to grow in response to rising demands for efficient flow and pressure control systems across industries such as oil and gas, chemicals, pharmaceuticals, and food processing. The expansion is driven not only by the increasing need for automation but also by innovations in actuator designs and valve materials that enhance reliability and performance.

Experts indicate that the growth in control valve technologies will be bolstered by ongoing developments in smart automation, with a particular focus on integrating IoT capabilities. These innovations enable real-time monitoring and control, facilitating more efficient processes and improved safety protocols. Moreover, the shift towards sustainable practices is prompting the adoption of advanced valve solutions that minimize energy consumption and reduce emissions, paving the way for a more environmentally responsible industrial sector. As such, businesses must stay abreast of these trends to ensure they are selecting the best control valves that align with their operational needs and future goals.

Related Posts

-

Exploring the Future of Control Valves: Innovations and Trends Driving Efficiency in Industry

-

7 Best Pressure Reducing Valves You Should Consider for Optimal Performance

-

How to Optimize Your System with Automated Valves for Maximum Efficiency

-

What is the Future of Automated Valves in Modern Industries

-

Why Investing in High-Quality Check Valves Can Reduce Operational Costs by Up to 30%

-

How to Optimize Hydraulic Flow Control for Maximum Efficiency

skip to Main Content

skip to Main Content