How to Choose the Right Flow Control Valves for Your Needs?

Selecting the right flow control valves can significantly impact operational efficiency. Experts in the field emphasize its importance. John Smith, a renowned engineer in valve technology, once stated, “Choosing the wrong valve can lead to significant losses in process control.” This insight reminds us that understanding flow control valves is crucial.

Flow control valves manage fluid flow rates effectively. However, the variety available can be overwhelming. Each application demands specific characteristics in a valve. For example, temperature and pressure ratings are vital. Some users may overlook sizing, which can affect performance. The choice isn’t trivial; it deserves careful thought.

Visualize a manufacturing plant where flow control valves operate under varying conditions. A small error in selection can cause inefficiencies. Therefore, acknowledging the complexities surrounding flow control valves is essential. Every detail matters in ensuring smooth operations. Mistakes can lead to costly downtime. Proper understanding is key to avoiding pitfalls.

Factors to Consider When Selecting Flow Control Valves

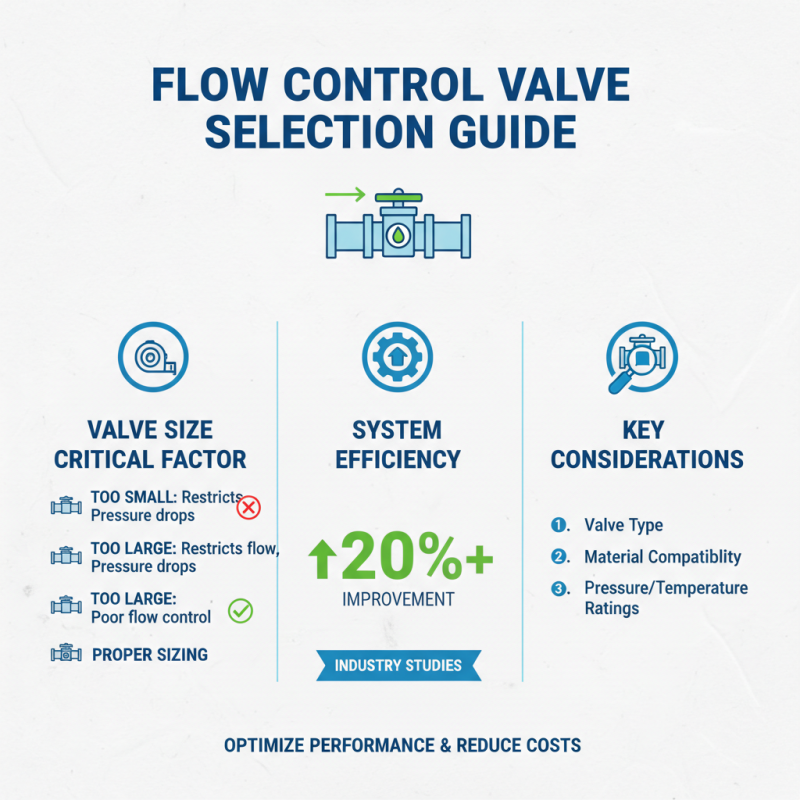

When selecting flow control valves, several factors must be considered. Valve size is critical. A valve that is too small can restrict flow and lead to pressure drops. Conversely, a valve that is too large may not control flow effectively. Proper sizing can improve system efficiency by 20% or more, according to industry studies.

Another important factor is the type of media being controlled. Different fluids have unique properties. Viscosity, temperature, and chemical compatibility can affect valve performance. For example, a valve suited for water may not work well with corrosive chemicals. Understanding these properties is crucial to avoid costly failures.

Finally, the application environment matters. External conditions, such as temperature fluctuations or vibration, can impact valve performance. It's essential to choose valves that can withstand these conditions. End-users often overlook this, leading to premature wear and tear. Regular maintenance is also vital for ensuring longevity and reliability in valve performance.

Types of Flow Control Valves and Their Applications

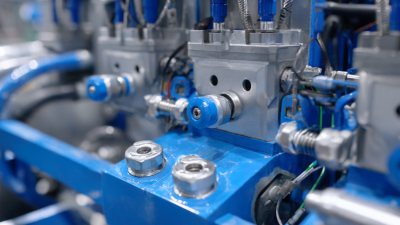

When selecting flow control valves, it's essential to understand the various types available and their specific applications. One common type is the needle valve. This valve offers precise control over fluid flow. It is ideal for applications requiring fine adjustments, such as in laboratory settings. The threaded design allows for small changes in flow rate, crucial for experiments.

Another important type is the globe valve. It is popular in industrial systems. The globe valve excels at throttling flow. It features a spherical body, which helps reduce turbulence. However, it may not be suitable for high-pressure applications. Users should reflect on their system requirements before choosing.

Lastly, check valve usage is vital in preventing backflow. These valves allow fluid to flow in one direction only. They are essential in applications where backflow could lead to system failure. Often overlooked, they play a key role in maintaining system integrity. Every application is unique, and the right valve can greatly enhance efficiency. Understanding their functions ensures optimal performance in every system.

Understanding Flow Capacity and Pressure Ratings

When selecting flow control valves, understanding flow capacity is crucial. Flow capacity refers to the maximum flow rate a valve can handle. It’s essential to determine the requirements of your system. Too little capacity can lead to bottlenecks. Excessive flow can cause damage. Analyzing your specific application is necessary. There are various ways to calculate flow rates. You might need help from manuals or experts.

Pressure ratings also play a significant role. Each valve has a maximum pressure it can withstand. Choosing a valve below this limit can result in failure. However, too high a pressure rating can increase costs unnecessarily. Assess your system’s pressure to avoid discrepancies. Sometimes, manufacturers provide vague guidelines. It’s essential to double-check these specifications to ensure safety.

Many users ignore these key factors. This can lead to operational issues. In some cases, experimentation with different valves can yield insights. You may face unforeseen challenges. Learning from these experiences is vital. Ultimately, thorough research and consideration will lead to better performance.

Flow Control Valves: Flow Capacity and Pressure Ratings

Material Considerations for Durability and Compatibility

When selecting flow control valves, material considerations play a crucial role in ensuring durability and compatibility. The right material can enhance the lifespan of valves significantly. Industries often rely on stainless steel, brass, and plastic for various applications. According to a report from the Flow Control Institute, nearly 70% of valve failures are due to material degradation over time.

Choosing materials resistant to corrosion is essential, especially in harsh environments. For example, stainless steel provides superior strength and resistance. In contrast, brass offers good ductility but may corrode if exposed to certain chemicals. A study by the American Society of Mechanical Engineers indicates that up to 30% of valves fail prematurely due to chemical incompatibility.

Not all materials suit every application. For instance, PTFE, known for its chemical resistance, is ideal for corrosive substances. However, it may be too soft for high-pressure applications. Incorrect material choice can lead to leaks or valve malfunctions. Understanding the fluid type and environmental conditions is critical for making informed decisions. Sometimes, the perfect valve might not be available, prompting a need for alternative solutions.

How to Choose the Right Flow Control Valves for Your Needs? - Material Considerations for Durability and Compatibility

| Material | Durability Rating | Corrosion Resistance | Temperature Range (°C) | Common Applications |

|---|---|---|---|---|

| Stainless Steel | High | Excellent | -200 to 400 | Oil & Gas, Water Treatment |

| Brass | Moderate | Good | -100 to 250 | Plumbing, HVAC |

| PVC | Low | Fair | 0 to 60 | Chemical Processing, Irrigation |

| Cast Iron | Very High | Poor | -20 to 250 | Steam Systems, Heavy Machinery |

| Aluminum | Moderate | Good | -40 to 150 | Aerospace, Automotive |

Maintenance Tips for Prolonging Valve Lifespan

Proper maintenance of flow control valves is essential for extending their lifespan. Regular inspection is a must. Look for leaks, unusual noises, and signs of wear. These indicators can help spot issues before they escalate. Cleaning valves periodically removes debris and prevents corrosion. A simple cloth can suffice for basic cleaning.

Consider these tips for better valve care. Identify your valve’s needs based on its application. Different environments demand unique maintenance schedules. For example, valves in corrosive environments need more frequent checks. Ensure that the fluid conditions align with the valve material.

Remember, over-tightening can damage valves. Always follow manufacturer's specifications when adjusting. This might seem trivial, but even small mistakes can lead to bigger problems. A bit of preventive care can make a significant difference. Don't overlook small inconveniences; they often signal deeper issues needing attention.

Related Posts

-

2025 How to Choose the Right Flow Valves for Your Industrial Needs

-

10 Essential Flow Control Valves Every Industry Should Consider

-

Ultimate Flow Valves Maintenance Checklist for Optimal Performance and Longevity

-

10 Tips for Choosing the Right Flow Valves for Your Business Needs

-

How to Optimize Hydraulic Flow Control for Maximum Efficiency

-

Innovative Flow Control Valves on Display at the 138th Canton Fair in 2025

skip to Main Content

skip to Main Content