How to Choose Between Pneumatic and Hydraulic Systems?

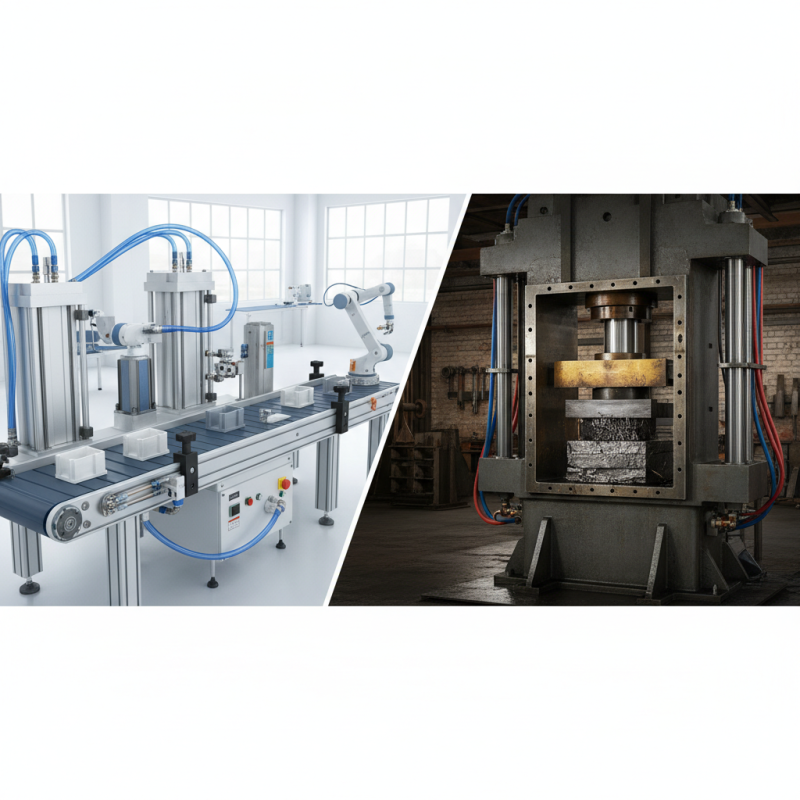

Choosing between pneumatic and hydraulic systems can be challenging. Each technology has distinct advantages and limitations. A report by the International Fluid Power Society highlights that pneumatic systems are often utilized in applications requiring rapid movement and lightweight components. In contrast, hydraulic systems are praised for their power and precision in heavy-duty applications.

Expert Phil Johnson, a renowned authority in the pneumatic hydraulic industry, states, "Understanding the specific needs of your application is crucial." This underlines the importance of assessing use cases when selecting between these systems. Pneumatic systems are typically more cost-effective, yet they may lack the force needed in heavier operations. Hydraulic systems deliver significant power but come with increased maintenance requirements.

The decision-making process requires careful consideration. Users must weigh factors like energy efficiency, operational speed, and force requirements. An inappropriate choice may lead to inefficiencies or excessive costs. Balancing these factors can seem overwhelming, yet it is vital to ensure optimal performance and reliability in systems relying on pneumatic hydraulic principles.

Introduction to Pneumatic and Hydraulic Systems

Pneumatic and hydraulic systems are essential in various industrial applications. Both systems utilize fluid to transmit power but differ in important aspects. Pneumatic systems use compressed air, while hydraulic systems use liquid. This distinction affects performance, efficiency, and application suitability.

Hydraulic systems deliver high power and force, often used in heavy machinery. According to industry reports, they can generate significantly more force than pneumatic systems. This makes them ideal for lifting and moving heavy loads. However, they can be prone to leaks, which may require more maintenance. Alternatively, pneumatic systems are lighter and cleaner. They are often favored in environments sensitive to contamination, such as food processing.

**Tips:** When selecting a system, consider working environment safety. Pneumatic systems are less likely to cause hazardous spills. Think about the required speed of operation. Pneumatics generally operate faster than hydraulics. Be mindful that while hydraulics can be powerful, they may also result in higher costs.

Overall, your choice between these systems depends on specific project needs. Always evaluate the trade-offs carefully. Balancing power, efficiency, and application will lead to better decision-making.

How to Choose Between Pneumatic and Hydraulic Systems?

| Feature | Pneumatic Systems | Hydraulic Systems |

|---|---|---|

| Operating Medium | Compressed Air | Hydraulic Fluid |

| Force Generation | Low to Moderate | High |

| Speed | Fast | Slower |

| Cost | Generally Lower | Generally Higher |

| Maintenance | Less Intensive | More Intensive |

| Applications | Packaging, Robotics | Construction, Metal Forming |

Key Operational Principles of Pneumatic Systems

When considering pneumatic systems, understanding their operational principles is crucial. Pneumatic systems utilize compressed air to perform work. They convert energy stored in air into mechanical motion. This principle allows for quick, efficient actuation. According to a report from the International Society of Automation, pneumatic systems can achieve an average response speed of 10 to 100 milliseconds.

One notable aspect is the system's simplicity. Pneumatic systems require fewer components compared to hydraulic systems. This simplicity can lead to lower maintenance costs. However, they are sensitive to temperature changes. Compressed air quality also impacts performance. Some studies indicate that about 70% of pneumatic failures are related to air quality issues. Dust, moisture, and oil can degrade system efficiency.

Moreover, pneumatic systems tend to have a limited power-to-weight ratio. They are lighter but often struggle with heavy loads. Some applications may find this limiting. Despite these challenges, their versatility remains appealing. They are widely used in industries for automation tasks. Ultimately, weighing these factors can guide one towards the right choice for specific applications.

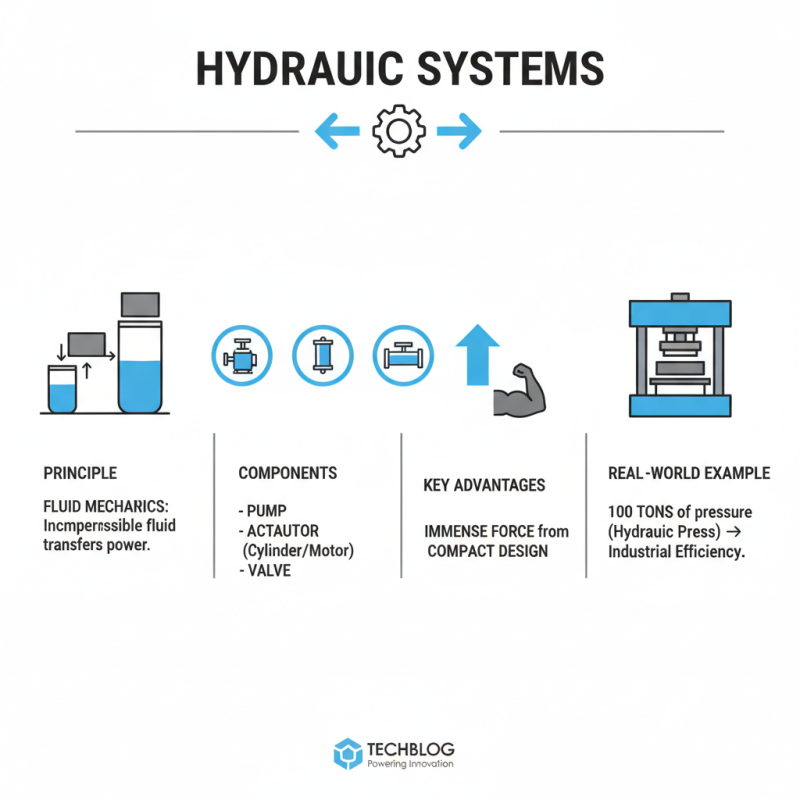

Key Operational Principles of Hydraulic Systems

Hydraulic systems operate on the principle of fluid mechanics. They use incompressible fluids to transfer power. The main components include pumps, actuators, and valves. These systems can generate immense force from compact designs. For example, a hydraulic press can exert up to 100 tons of pressure, attracting industries that value efficiency.

In practice, hydraulic systems are favored for heavy machinery. They excel at lifting and moving heavy loads with precision. However, they require regular maintenance. Any fluid leaks can compromise safety and efficiency. Reports show that over 30% of hydraulic system failures are due to poor maintenance practices. Operators need training to handle these systems effectively.

Despite their advantages, hydraulic systems have limitations. They may not perform well in extreme temperatures. Additionally, fluid viscosity can change over time, affecting performance. System designs should consider these factors for optimal operation. Reflections on current practices often reveal room for improvement. Implementing better training and preventive maintenance can enhance system reliability.

Comparative Analysis of Advantages and Disadvantages

When choosing between pneumatic and hydraulic systems, it’s vital to weigh their respective advantages and disadvantages. Pneumatic systems use compressed air. They are typically lighter and easier to maintain. These systems can operate in extreme environments, but air compressibility can lead to a lack of precision. Think about applications requiring precise control. In such cases, pneumatic systems might fall short.

Hydraulic systems, on the other hand, use fluid pressure. They offer high force density and are more efficient for heavy lifting tasks. They can achieve greater power with a smaller footprint. However, they often require more maintenance due to fluid leaks. Maintenance can be costly and complex. Consider the potential downtime when leaks occur. This reliance on fluid can create challenges in certain environments.

Both systems have their flaws. Pneumatic systems may be too imprecise for certain tasks. Hydraulic systems can face issues with leaks and maintenance. Each choice presents a trade-off. Analyze your specific needs and priorities carefully before making a decision. Doing so ensures you select the most suitable system for your applications.

Comparative Analysis of Pneumatic and Hydraulic Systems

This chart presents a comparative analysis of pneumatic and hydraulic systems based on their advantages and disadvantages. The scores indicate strength on a scale of 1 to 10, with higher values denoting stronger advantages or fewer disadvantages.

Factors to Consider When Choosing a System

Choosing between pneumatic and hydraulic systems can be challenging. Several factors must be considered to make an informed decision. One important factor is the application of the system. Pneumatic systems work well for high-speed operations. They can handle rapid movement efficiently. In contrast, hydraulic systems excel in lifting heavy loads. They provide greater force, which is critical in construction and manufacturing.

Cost is another significant aspect. According to industry reports, pneumatic systems tend to be cheaper to install and maintain. However, hydraulic systems often have lower lifetime operating costs due to their efficiency in energy use. An installation might seem more budget-friendly initially, but ongoing expenses can alter this view. It’s essential to analyze long-term costs rather than just upfront expenses.

Finally, environmental considerations matter. Pneumatic systems use compressed air and are generally less affected by temperature. Hydraulic systems, however, may leak fluids, posing contamination risks. This factor demands reflection on broader environmental impacts. Not all settings are suited to each system type, and both have their shortcomings. Understanding these nuanced details can help guide your choice effectively.

Related Posts

-

Ultimate Checklist for Global Buyers in Fluid Power Procurement

-

Ultimate Guide to Mastering Hydraulic Flow Control Techniques for Optimal Performance

-

Why Hydraulic Continental Systems Are Essential for Modern Engineering?

-

Top Hydraulic Flow Control Techniques for Efficient Systems?

-

2025 How to Understand Fluid Power Hydraulics for Beginners and Experts

-

Why Understanding Hydraulic Parts is Essential for Your Machinery Efficiency

skip to Main Content

skip to Main Content