2026 Best Hydraulic Pressure Relief Valves for Optimal Performance?

In the fast-evolving industry of hydraulic systems, hydraulic pressure relief valves play a critical role. They ensure equipment safety and optimal performance under various conditions. Renowned expert in hydraulic engineering, Dr. Emily Harper, emphasizes, “The right relief valve can enhance system efficiency and prevent catastrophic failures.” This insight underlines the significance of selecting the best hydraulic pressure relief valves available.

Choosing the ideal valve can be challenging. Numerous options exist, each with unique specifications. Factors such as flow rate, pressure settings, and materials need careful consideration. Too often, users overlook these details, leading to inefficiencies or equipment damage.

A common mistake is assuming all hydraulic pressure relief valves are the same. In reality, the wrong choice can result in costly downtime and repairs. Reflection on these aspects is crucial for each business. A well-informed decision can lead to better performance and reliability.

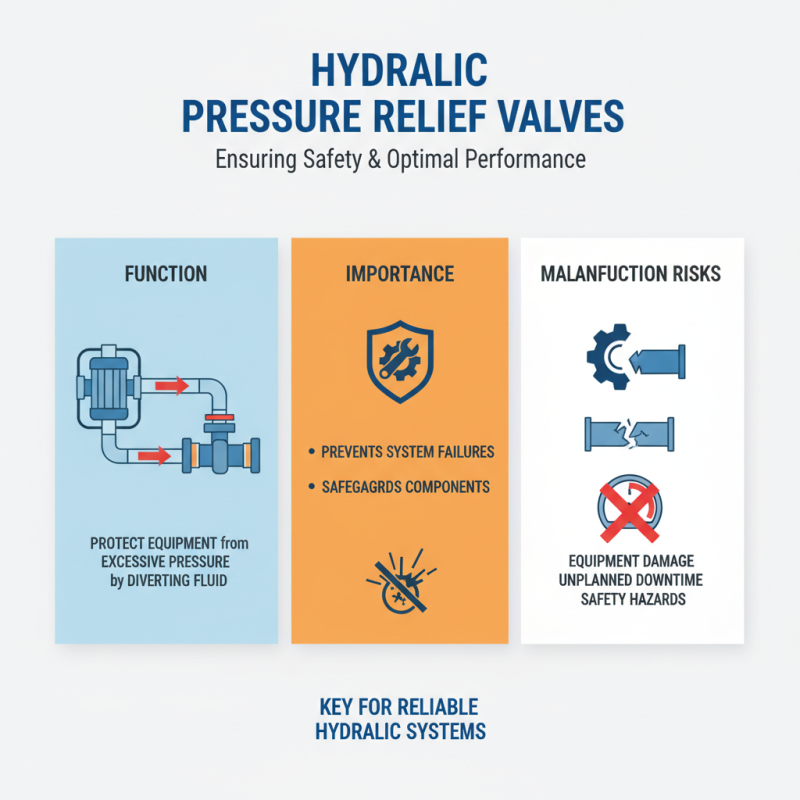

Understanding Hydraulic Pressure Relief Valves and Their Importance

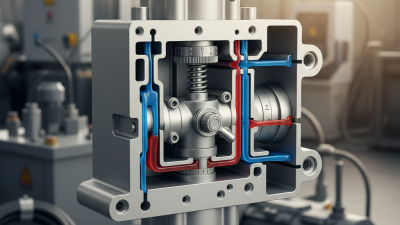

Hydraulic pressure relief valves are crucial components in hydraulic systems. They ensure safety by protecting equipment from excessive pressure. A malfunction can lead to serious failures. Therefore, understanding their functionality is essential for optimal performance.

These valves regulate pressure by opening or closing under specific conditions. When the pressure exceeds a set limit, they divert fluid back to the reservoir. This prevents damage to hydraulic components. However, improper adjustment can compromise their effectiveness. Regular maintenance is necessary to ensure accurate pressure settings.

An ideal hydraulic pressure relief valve should respond quickly to pressure changes. Some valves may struggle under varying conditions, leading to inconsistent performance. This inconsistency warrants careful evaluation. Operators often overlook this aspect, which can lead to system inefficiencies. Recognizing these flaws in performance helps in selecting the best valve for specific applications.

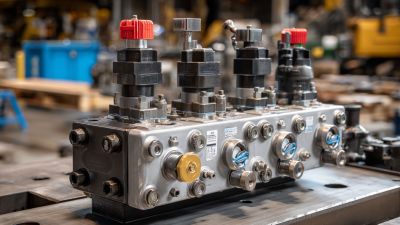

Key Features to Look for in High-Performance Hydraulic Relief Valves

When choosing hydraulic pressure relief valves, certain features stand out. Look for valves that offer

consistent performance under varying pressure conditions. Precision in pressure adjustments is crucial. A valve that can adapt quickly will minimize system risks.

Another key feature is the material quality. High-performance valves often use durable metals or composites. They resist corrosion and wear. This longevity can reduce maintenance needs significantly. Also, consider the size and compatibility. Ensure the valve fits your system's requirements. A mismatched size can lead to inefficiencies.

Tips to remember: Always check the valve’s pressure rating. A mismatch can cause safety hazards. Pay attention to the installation process. A poorly installed valve can result in failure. Regular maintenance checks can also prolong the valve’s life.

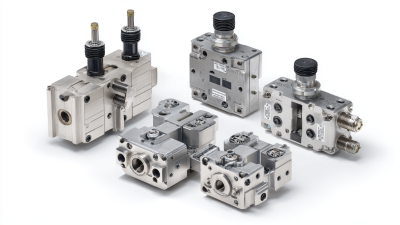

Top Brands and Models of Hydraulic Pressure Relief Valves in 2026

In 2026, selecting the best hydraulic pressure relief valves involves evaluating various brands and models that stand out in performance and reliability. Industry reports indicate that the market for hydraulic components is projected to grow by over 5% annually. This growth underscores the rising demand for high-quality valves that ensure system efficiency. Users are increasingly seeking valves that provide precise control over pressure levels, reducing the risk of equipment failure.

Top-performing hydraulic pressure relief valves prioritize durability and responsiveness. Studies reveal that models featuring stainless steel construction show a 30% increase in lifespan compared to traditional materials. This durability directly correlates with reduced maintenance needs, making them a preferable choice for industries relying on heavy machinery. A shift towards servo-operated designs is also notable, providing quicker response times and enhanced pressure accuracy.

However, not every model meets the expected standards. Some valves struggle with excessive leakage, affecting overall system performance and safety. Users must conduct thorough evaluations of performance metrics and user reviews. This scrutiny can prevent costly mistakes, especially in demanding operational settings. Balancing quality with cost will remain a challenge as manufacturers innovate to meet and exceed market expectations.

Performance Comparison of Hydraulic Pressure Relief Valves (2026)

Installation and Maintenance Tips for Optimal Valve Performance

Proper installation and maintenance are crucial for hydraulic pressure relief valves. Start by ensuring the valve is suitable for your system's specifications. Improper sizing can lead to inefficiencies and potential system failures. Pay attention to the orientation during installation. A misaligned valve may cause leaks or malfunctions, hindering optimal performance.

Regular maintenance is key to keeping the valve in good working condition. Inspect the valve periodically for signs of wear or damage. Look for leaks around connections and monitor the pressure settings. It’s important to clean the valve frequently. Dirt and contaminants can cause blockages, impacting its functionality. Be prepared for potential issues. Sometimes, despite your best efforts, valves may still underperform. Reflecting on these experiences can help improve future installations.

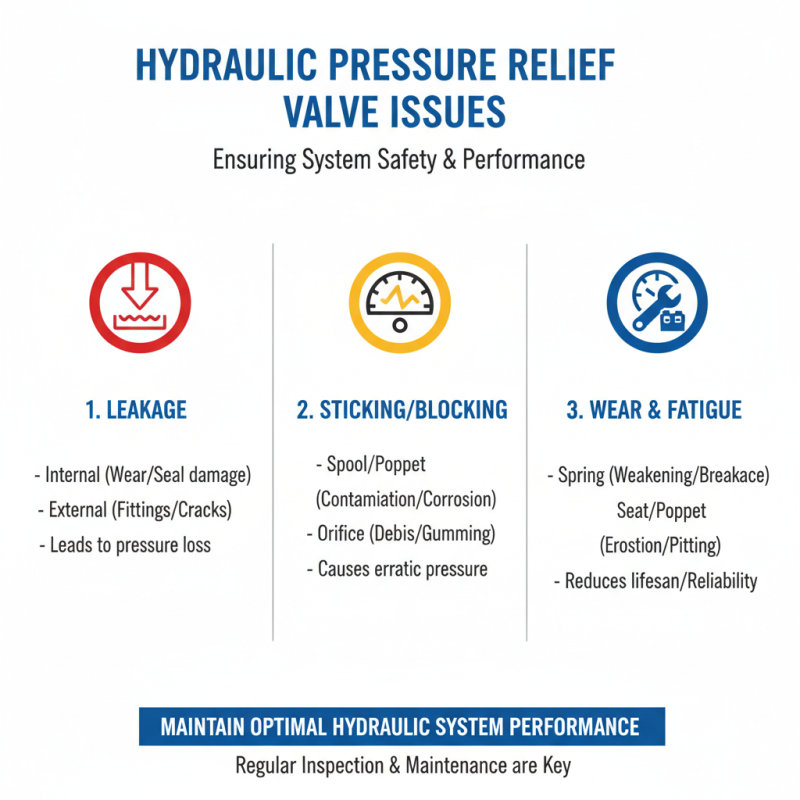

Common Issues and Troubleshooting Techniques for Relief Valves

Hydraulic pressure relief valves are crucial for system safety. However, they can face various issues. Understanding these problems is essential for maintaining optimal performance.

Common problems include leaks, sticking valves, and improper pressure settings. Leaks typically occur from worn seals or connection points. A report by the International Journal of Engineering reveals that about 30% of hydraulic failures stem from such leaks. Sticking occurs when debris accumulates, hindering movement. Regular maintenance and proper filtration can minimize these issues.

Tips for troubleshooting involve routine checks and systematic inspections. Look for signs of wear on seals and fittings. Clear any debris around the valves. Adjust pressure settings based on specific system requirements. Remember to document performance changes to identify patterns over time. Tracking these factors can lead to more effective solutions. Addressing these common issues early can enhance valve reliability and prolong system life.

Related Posts

-

Top 10 Hydraulic Pressure Relief Valves for Optimal Equipment Performance

-

7 Essential Tips for Choosing Hydraulic Flow Control Valves for Your Business

-

Understanding the Essential Role of Continental Hydraulic Valves in Modern Industry

-

Why Hydraulic Flow Control Valves Are Essential for Optimal Machinery Performance

-

7 Essential Tips for Maximizing the Life of Your Continental Hydraulic Pump

-

How to Optimize Hydraulic Flow Control Valves for Maximum Efficiency

skip to Main Content

skip to Main Content