5 Best Fluid Power Hydraulics Solutions for Optimal Performance

In today's fast-paced industrial landscape, achieving optimal performance in machinery and equipment is paramount, and fluid power hydraulics stands at the forefront of this endeavor. As industries increasingly rely on hydraulic systems for their efficiency and reliability, it becomes crucial to explore the best solutions that can enhance performance and productivity. This guide delves into the five best fluid power hydraulics solutions tailored for diverse applications, providing insights into innovative technologies, best practices, and maintenance tips.

By understanding the intricacies of fluid power hydraulics, businesses can not only improve operational efficiency but also reduce downtime and increase overall performance, setting the stage for sustainable growth and success in their respective fields. Join us as we navigate through these essential solutions that promise to elevate your hydraulic systems to new heights.

Understanding Fluid Power: Key Statistics and Trends in Hydraulics Performance Optimization

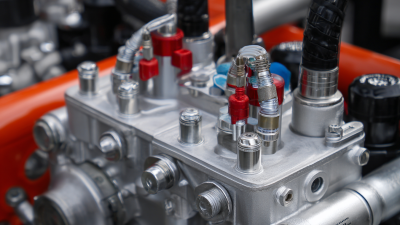

Understanding fluid power is essential for optimizing hydraulics performance in industrial applications. Today, hydraulic systems play a crucial role in various sectors, accounting for approximately 30% of energy usage in industrial machinery. Key statistics highlight that properly maintained hydraulic systems can enhance overall efficiency, reduce energy consumption by up to 15%, and lower operational costs significantly.

To maximize performance, it’s important to regularly perform system audits. This involves checking fluid levels, inspecting for leaks, and ensuring that all components are functioning optimally. Another tip is to keep hydraulic fluids clean; contamination can lead to costly downtime and repairs. By using filtration systems, businesses can prolong the life of hydraulic components and maintain peak performance.

Additionally, integrating technology such as predictive maintenance tools can greatly improve hydraulic system reliability. These tools utilize data analytics to forecast potential issues before they lead to failures. Implementing such systems not only boosts operational efficiency but also supports proactive decision-making to enhance performance metrics.

Top 5 Hydraulic Fluids and Their Impact on System Efficiency: What the Data Reveals

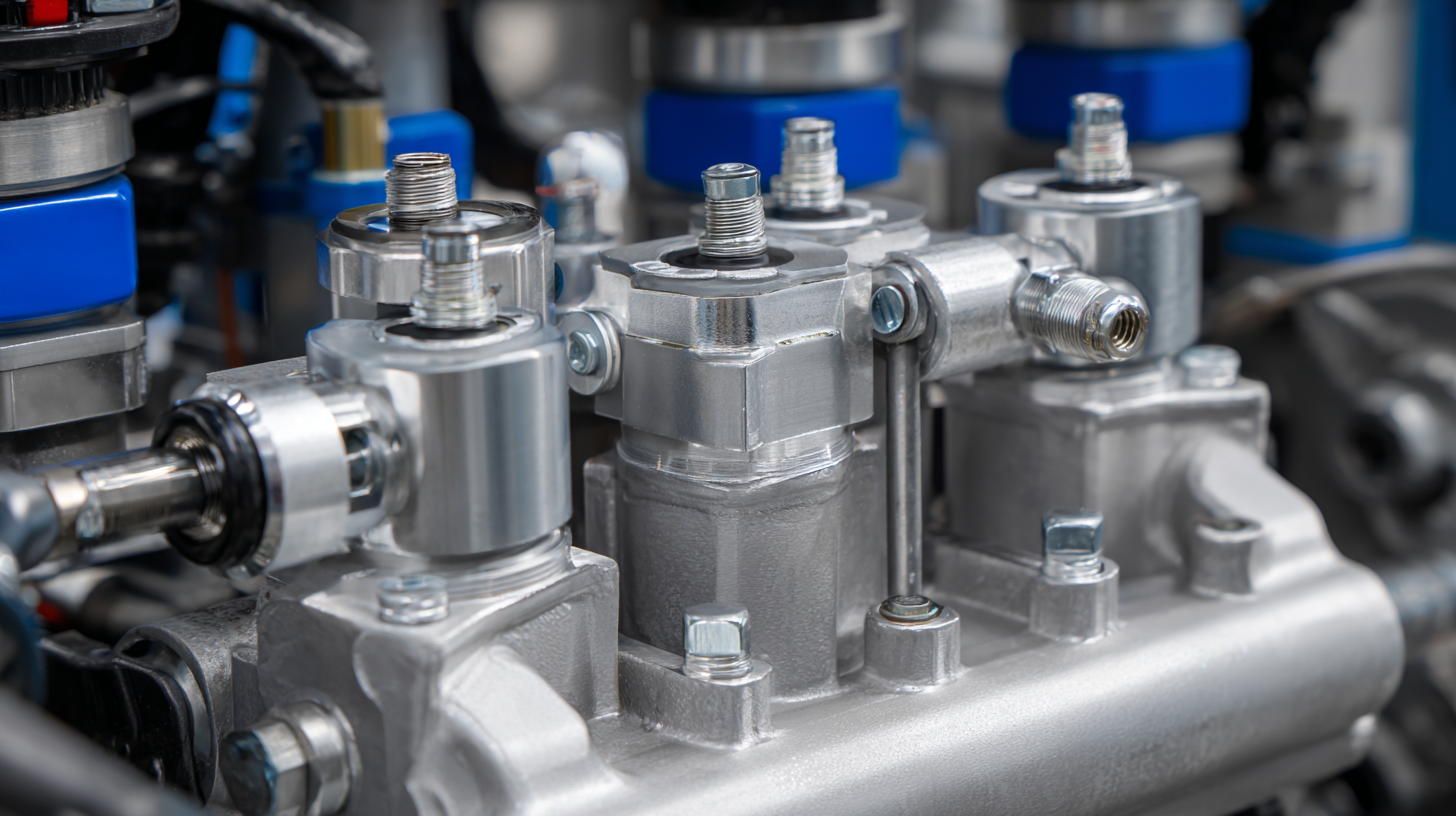

Hydraulic systems play a crucial role in the performance of fluid power applications, and the type of hydraulic fluid used can significantly impact efficiency. The right fluid not only ensures optimal operation but also enhances the system's longevity. Recent data reveals that higher viscosity index fluids can reduce the energy lost to friction, leading to better system performance. In addition, selecting fluids with superior lubricating properties can minimize wear and tear on components, ultimately translating to cost savings in maintenance and downtime.

Hydraulic systems play a crucial role in the performance of fluid power applications, and the type of hydraulic fluid used can significantly impact efficiency. The right fluid not only ensures optimal operation but also enhances the system's longevity. Recent data reveals that higher viscosity index fluids can reduce the energy lost to friction, leading to better system performance. In addition, selecting fluids with superior lubricating properties can minimize wear and tear on components, ultimately translating to cost savings in maintenance and downtime.

Moreover, the biodegradability of hydraulic fluids is becoming increasingly important in today’s environmentally conscious landscape. Eco-friendly fluids not only help in reducing environmental impact but also offer excellent performance under various operating conditions. Studies indicate that using such fluids can improve system efficiency by up to 15%, making them a compelling choice for industries aiming to balance performance with sustainability. Understanding the characteristics and applications of different hydraulic fluids is essential for engineers and decision-makers striving for optimal system efficiency.

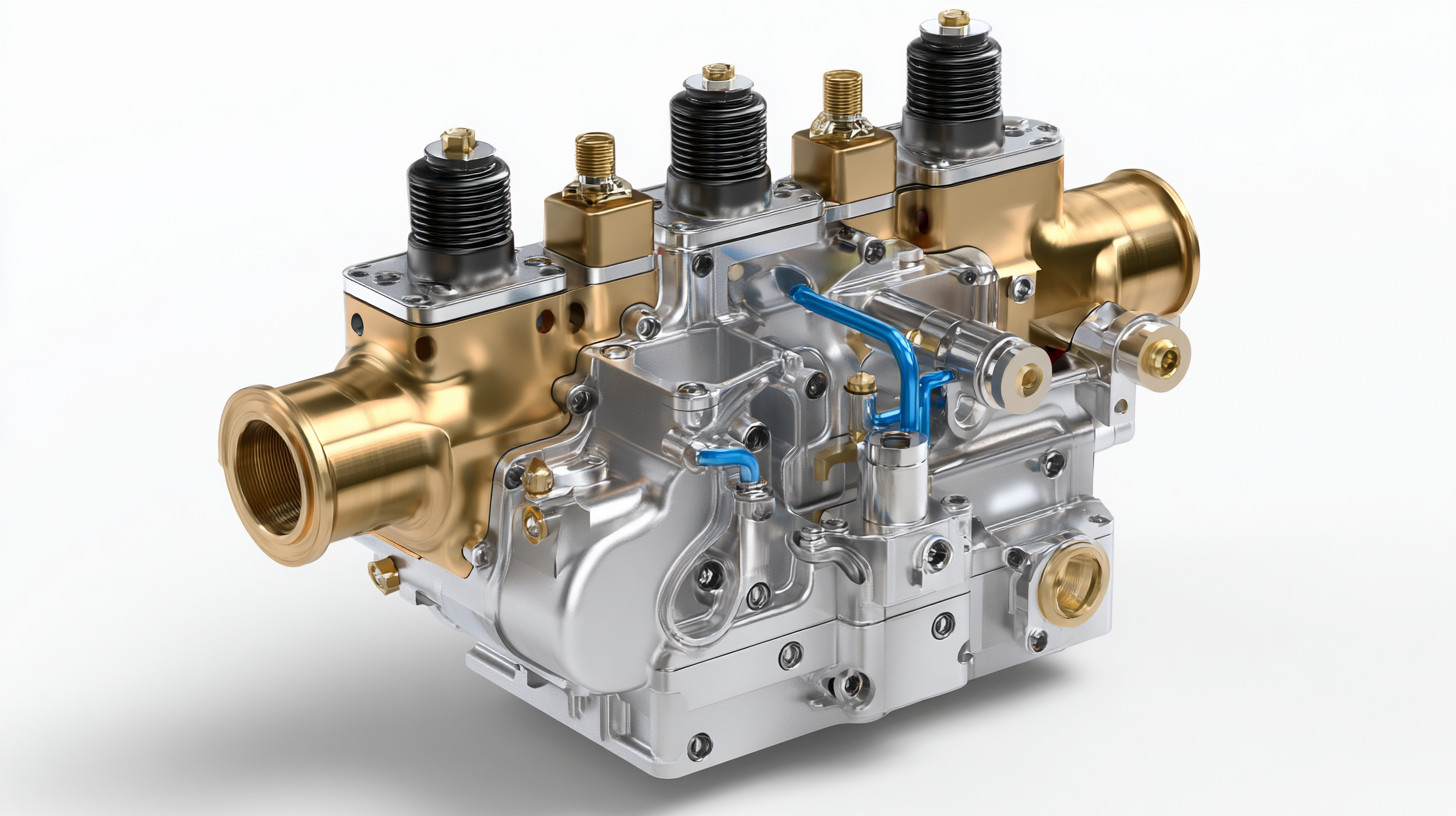

The Role of Hydraulic Cylinders: Performance Metrics and Maintenance Tips for Longevity

Hydraulic cylinders play a crucial role in fluid power systems, serving as the backbone for various applications ranging from manufacturing to construction. According to a report by the International Hydraulic Institute, hydraulic cylinders account for over 30% of the total maintenance costs in heavy machinery. Therefore, understanding their performance metrics and implementing proper maintenance strategies is essential for ensuring optimal functionality and longevity.

To maximize performance, it’s critical to monitor key metrics such as stroke speed, pressure, and load capacity. Regularly inspecting these elements can help identify potential issues before they escalate. For instance, maintaining the hydraulic fluid at the manufacturer-specified viscosity can enhance efficiency by up to 15%.

Tips for maintenance:

- Schedule routine inspections to check for leaks and wear on seals, which can significantly impact performance.

- Regularly change the hydraulic fluid and filter to prevent contamination, which is one of the leading causes of system failure.

Integration of Smart Technology in Hydraulics: Data-Driven Insights for Enhanced Performance

The integration of smart technology into fluid power hydraulics marks a significant leap forward in enhancing system performance. By leveraging data-driven insights, industries can analyze and optimize hydraulic operations in real time. This not only leads to improved efficiency and reduced downtime but also enhances predictive maintenance capabilities.

Utilizing machine learning algorithms enables systems to learn from historical data, allowing for proactive adjustments that optimize fluid dynamics and resource usage.

Moreover, the confluence of smart water management systems and renewable energy sources, such as photovoltaic pumping, presents an innovative approach to meet the water supply needs of rural communities.

This solution embodies sustainability, harnessing the power of solar energy while implementing intelligent monitoring techniques to ensure optimal water distribution and usage. As these technologies continue to evolve, the potential for smart solutions to revolutionize hydraulic systems and water management becomes increasingly evident.

The future is clearly geared toward creating more resilient and efficient infrastructures that cater to both industrial and community needs.

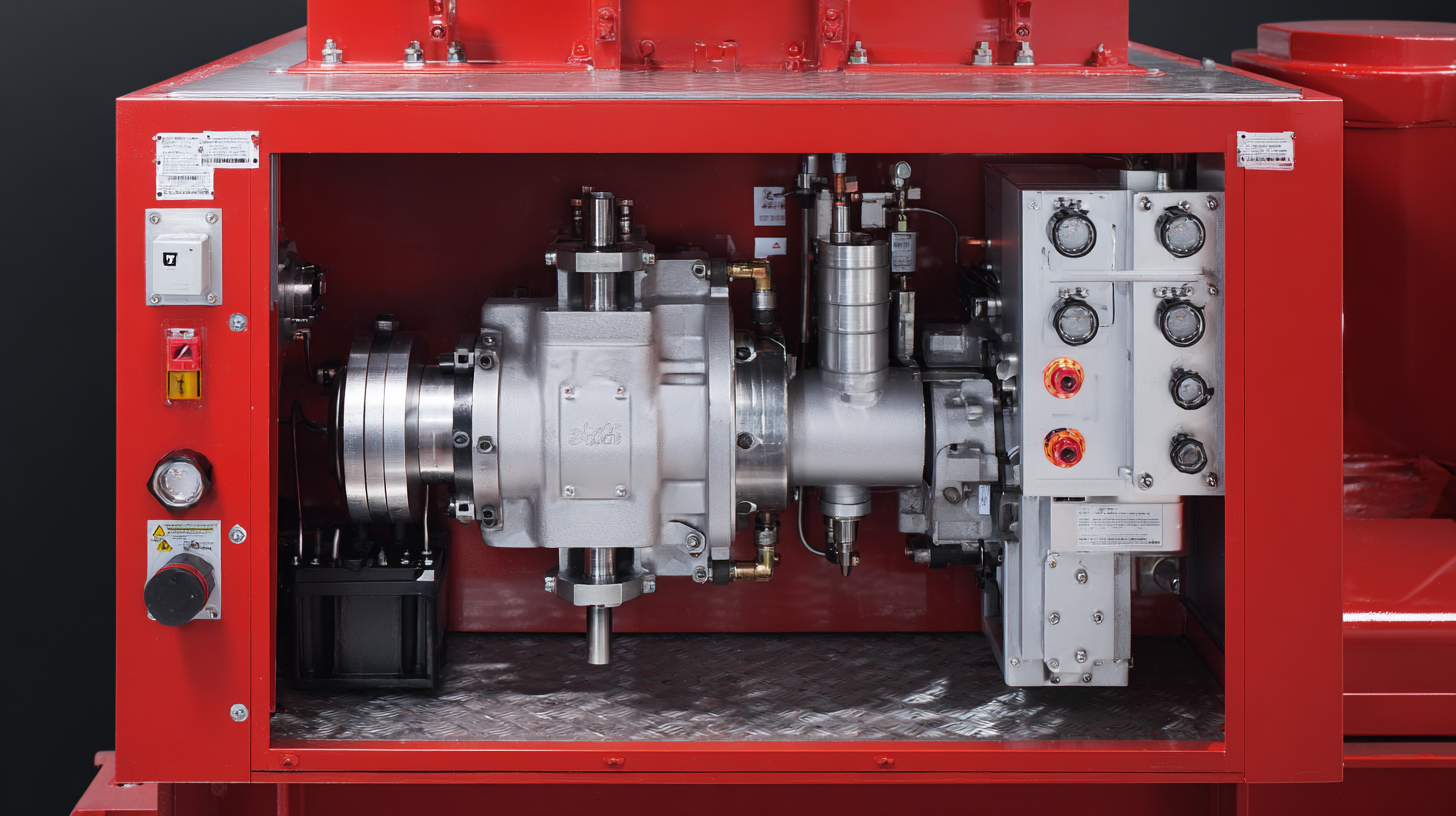

Evaluating Hydraulic Pump Efficiency: Benchmarking Techniques and Performance Improvement Strategies

When assessing the efficiency of hydraulic pumps, benchmarking techniques play a pivotal role in identifying areas for performance enhancement. Industry reports suggest that optimizing pump efficiency can lead to energy savings of up to 30%. The Hydraulic Institute provides methodologies that compare existing pump systems against established performance metrics, ensuring that businesses can identify deviations early and implement corrective measures. This proactive approach is essential in reducing operational costs while enhancing system reliability.

Furthermore, performance improvement strategies are integral to maximizing hydraulic pump efficiency. Regular maintenance schedules can significantly reduce wear and tear, leading to a typical extension of pump lifespan by 25%. Techniques such as the implementation of variable frequency drives (VFDs) can adapt pump speed to operational needs, thereby minimizing energy consumption during low-demand periods. A recent report by the Energy Efficiency of Pumps Initiative emphasized that companies adopting these strategies not only improve their hydraulic system's output but also contribute to sustainability efforts by reducing energy usage and greenhouse gas emissions over time. Adopting these best practices will ensure optimal performance and longevity of hydraulic systems in any industrial setting.

Hydraulic Pump Efficiency Benchmarking

Related Posts

-

Ultimate Checklist for Global Buyers in Fluid Power Procurement

-

What Are the Key Components of Hydraulics Products and Their Applications

-

12 Key Reasons Why Directional Control Valves Are Essential for Efficient Fluid Power Systems

-

10 Tips for Choosing the Right Flow Valves for Your Business Needs

-

Ultimate Guide to Understanding Check Valves and Their Applications

-

Ultimate Guide to Mastering Hydraulic Flow Control Techniques for Optimal Performance

skip to Main Content

skip to Main Content