What are the Benefits of Proportional Valves in 2026?

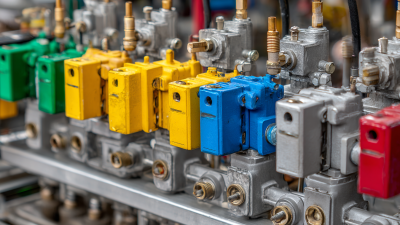

The growing importance of proportional valves in 2026 cannot be ignored. These components are crucial in various industries, enhancing efficiency and precision in fluid control. Proportional valves regulate flow and pressure with unmatched accuracy. This leads to better performance in hydraulic systems.

In applications ranging from automotive to aerospace, the benefits of proportional valves are evident. They allow for more responsive operations and adaptability in various conditions. However, challenges remain. The complexity of integration can lead to operational issues. Proper understanding and implementation are essential.

These valves also bring environmental considerations. Improved energy efficiency can reduce the carbon footprint in various processes. Nonetheless, the initial investment often raises questions. Balancing cost and benefit requires careful analysis. In exploring proportional valves, one must reflect on their role in future technologies.

Benefits of Proportional Valves in 2026: An Overview

Proportional valves are pivotal for modern hydraulic systems in 2026.

These valves provide precise control over fluid flow and pressure. A recent report indicated a

25% increase in efficiency when using proportional valves.

This improvement directly correlates with reduced energy consumption in various industrial applications.

The ability to modulate based on demand leads to better performance. In sectors like manufacturing, energy savings can result in substantial cost reductions.

However, implementing proportional valves often requires a considerable initial investment. Some companies struggle to justify these costs in a tight budget scenario.

Additionally, training staff to operate such systems presents challenges.

Durability is often a concern. While many proportional valves are designed for longevity, the complexity can lead to maintenance issues.

An estimated 15% of users reported frequent service disruptions.

This creates a dilemma for businesses trying to balance efficiency and reliability. Despite these factors, the overall trend suggests that

the benefits of proportional valves far outweigh the challenges for those

willing to invest in proper training and maintenance.

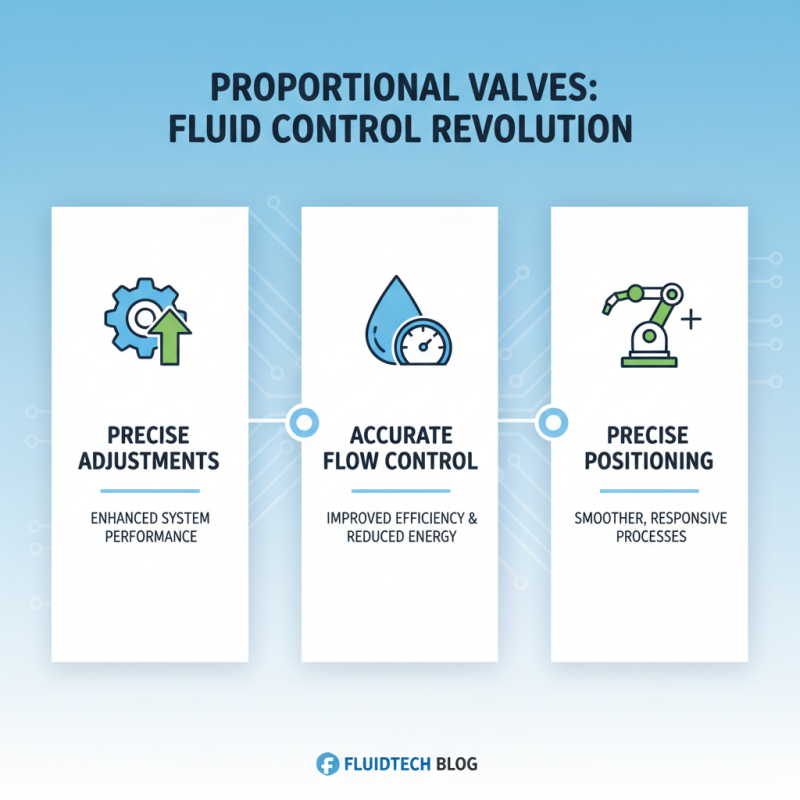

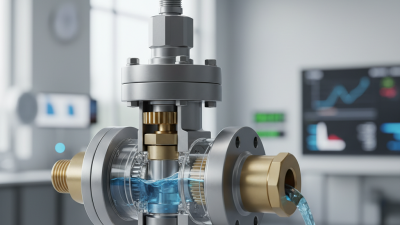

Improved Precision in Fluid Control with Proportional Valves

Proportional valves have revolutionized fluid control in various industries. By allowing precise adjustments, they enhance system performance. With these valves, operators can control flow rates accurately. This leads to improved efficiency and reduced energy consumption. The technology allows for more exact positioning in automated systems. As a result, processes become smoother and more responsive.

However, the implementation of proportional valves isn’t always flawless. Sometimes, they can fail to provide the desired precision. This might be due to set-up errors or calibration issues. In complex systems, even minor discrepancies can lead to significant problems. Regular maintenance and proper adjustments are critical. Without these, the benefits might not be fully realized.

In 2026, the demand for improved precision will grow. Industries will seek ways to optimize their fluid management. The right proportional valves can play a crucial role here. Still, users should remain attentive to their limitations. Continuous learning and adaptation will be fundamental for effective fluid control. The journey towards achieving perfect precision is ongoing.

Enhanced Energy Efficiency and Sustainability in 2026 Applications

Proportional valves offer significant advantages for energy efficiency and sustainability in various applications by 2026. Recent studies indicate that these valves can enhance system performance by reducing energy consumption by up to 30%. This is crucial in sectors where energy costs are a primary concern. By modulating flow and pressure, proportional valves help minimize waste and optimize machine cycling.

The integration of proportional valves leads to smoother operation and precision control. Reports show that equipment fitted with these valves demonstrate a notable reduction in energy spikes during operation. Users reported decreased carbon footprints due to energy savings and improved operational efficiency, which directly correlates with sustainable practices.

However, the transition to proportional valves is not without challenges. There remains a learning curve for operators who need to adjust to new systems. In some cases, initial costs can deter companies from upgrading existing equipment. The industry is aware of these hurdles, emphasizing the need for ongoing training and support. Addressing issues of integration could further bolster the benefits of these advanced valves in achieving a greener future.

Increased Flexibility and Customization of Fluid Systems

Proportional valves are becoming increasingly vital in today's fluid systems. In 2026, their flexibility is more crucial than ever. Reports indicate that 70% of industries using these valves experience improved system performance. This advancement allows for real-time adjustments in flow and pressure. Consequently, engineers can tailor operations to specific needs.

Customization is a game changer. Systems can be fine-tuned to enhance performance based on application requirements. For example, in manufacturing, a 15% increase in efficiency can be attributed to precise fluid control. However, adaptability comes with challenges. Not all systems can seamlessly integrate proportional valves, leading to possible friction in implementation.

Industry analysis shows a rising trend in adopting smart technologies alongside these valves. Over 50% of companies are expected to incorporate IoT solutions by 2026. This integration offers greater control and data analytics capabilities. Still, organizations must reflect on fitting these technologies into existing frameworks. Balancing innovation with practicality remains a point of contention.

What are the Benefits of Proportional Valves in 2026? - Increased Flexibility and Customization of Fluid Systems

| Benefit | Description | Application | Impact |

|---|---|---|---|

| Enhanced Control | Allows for precise regulation of fluid flow and pressure. | Automotive and industrial machinery. | Improves efficiency and performance of systems. |

| Increased Customization | Can be tailored to specific system requirements and dynamics. | Hydraulic systems in diverse industries. | Enhances adaptability to unique applications. |

| Energy Efficiency | Reduces energy consumption by optimizing flow rates. | Manufacturing processes. | Lowers operational costs and environmental impact. |

| Improved Responsiveness | Faster reaction times to system demands. | Robotics and automation technology. | Increases productivity and reduces downtime. |

| Reduced Wear and Tear | Minimizes stress on components through better flow control. | Construction and agricultural equipment. | Extends equipment lifespan and reliability. |

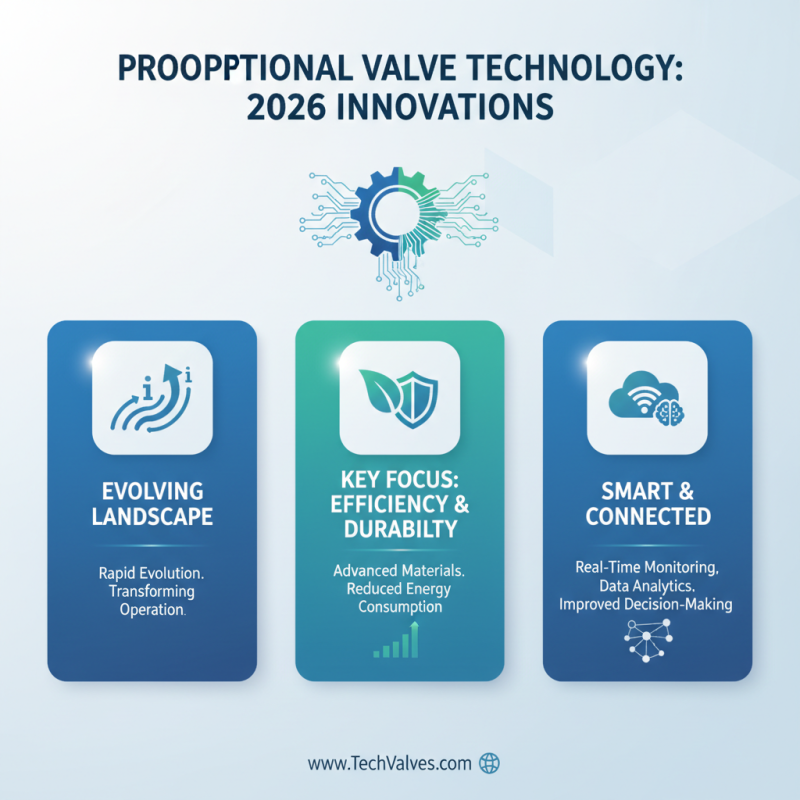

Future Innovations and Trends in Proportional Valve Technology

The landscape of proportional valve technology is evolving rapidly. Innovations in 2026 are transforming how these valves operate. Efficiency will be a major focus. Advanced materials are enhancing durability and performance. This shift can reduce energy consumption significantly. Smart sensors may enable real-time monitoring. Data analytics will improve decision-making processes.

Additionally, integration with IoT devices is a trend to watch. Connected systems can provide insights and enhance control. However, not all manufacturers are embracing this change. Some may resist due to costs or lack of expertise. This reluctance could hinder their competitiveness.

Moreover, user-friendly designs are becoming essential. Simplicity in operation attracts more users. Yet, achieving this can be challenging. Balancing complexity with usability requires careful thought. Feedback loops from users are crucial. They can guide future enhancements. Understanding user needs will drive better innovations.

Related Posts

-

2026 Top Proportional Valves for Precision Control in Automation

-

Essential Checklist for Selecting the Right Proportional Valves for Your Applications

-

How to Effectively Manage Pressure Control Techniques?

-

Understanding the Importance of Directional Control Valves in Fluid Power Systems

-

Exploring Hydraulic Continental Solutions at the 138th Canton Fair 2025 Trends and Market Data

-

The Ultimate Guide to Pressure Regulating Valves and Their Applications

skip to Main Content

skip to Main Content