Revolutionizing Flow Control: How Automated Valves are Shaping the Future of Industrial Automation

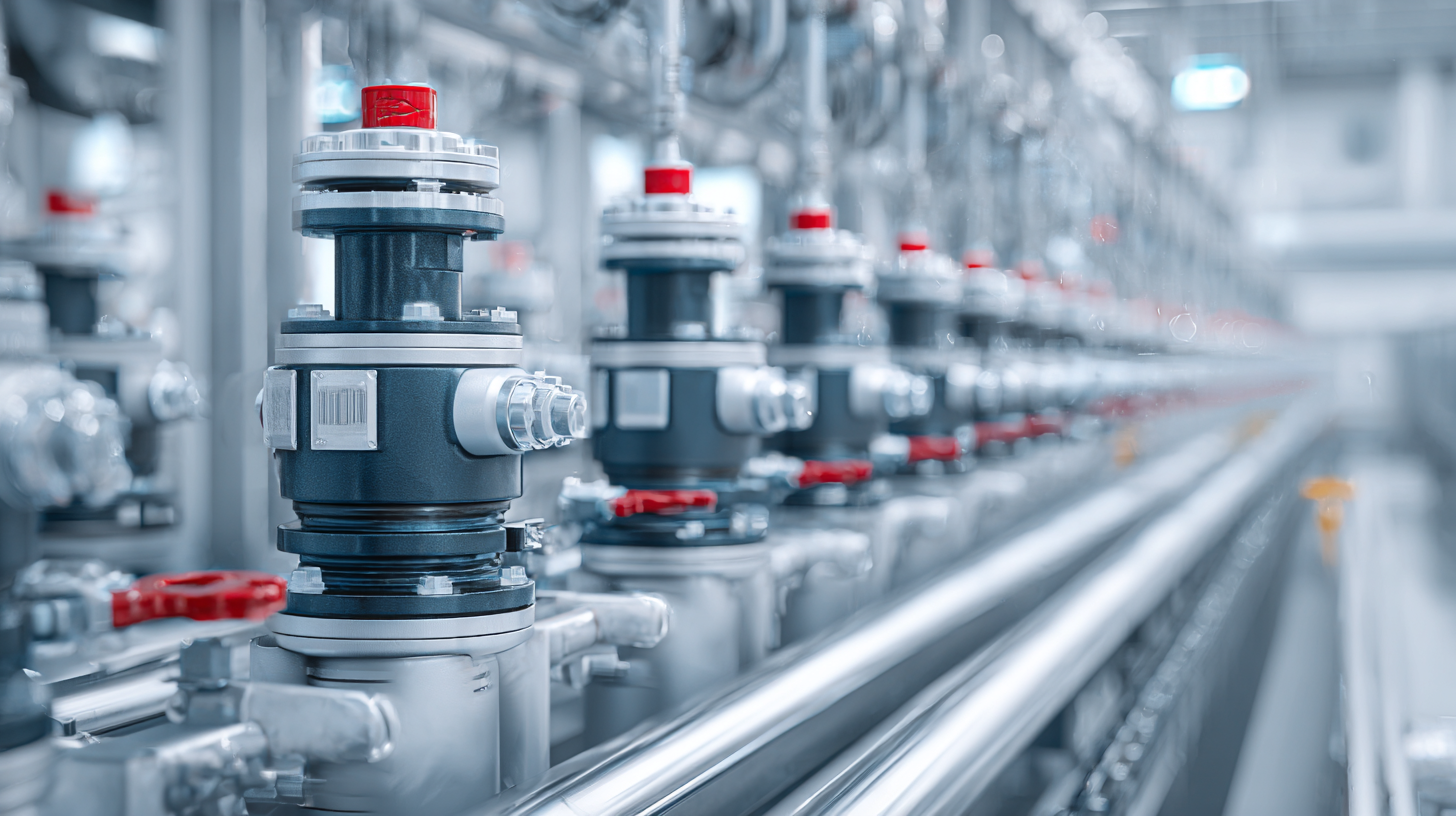

In the ever-evolving landscape of industrial automation, automated valves are at the forefront of innovation, significantly enhancing flow control processes across various sectors. According to a recent report by MarketsandMarkets, the global automated valves market is projected to reach USD 7.3 billion by 2026, growing at a CAGR of 6.5%. This surge is attributed to the increasing demand for efficiency and safety in industries such as oil and gas, water and wastewater management, and food and beverage processing.

As companies strive for smarter and more sustainable operations, automated valves offer unparalleled precision and reliability, minimizing human intervention while optimizing flow management. By integrating advanced technologies such as IoT and AI, these components are not only transforming traditional flow control methods but are also setting new standards for productivity and operational excellence in industrial environments.

Impact of Automated Valves on Efficiency and Productivity in Industrial Processes

Automated valves are rapidly transforming the landscape of industrial automation, significantly impacting efficiency and productivity across various processes. According to a report by MarketsandMarkets, the global automated valves market is projected to reach $12.3 billion by 2026, expanding at a CAGR of 5.3% from 2021. This growth reflects the increasing adoption of automation technologies in industries such as oil and gas, water and wastewater management, and manufacturing, where the need for precision control and increased throughput is paramount.

Moreover, the implementation of automated valves can lead to substantial operational savings. A study conducted by ARC Advisory Group indicates that industries integrating automated valve systems can achieve efficiency improvements of up to 30%, alongside a significant reduction in cycle times. With the application of smart technologies like IoT and AI, these valves not only enhance operational reliability but also provide real-time data analytics, allowing for proactive maintenance and reduced downtime. As industries increasingly prioritize sustainability and operational efficiency, the role of automated valves will continue to be pivotal in shaping the future of industrial processes.

Key Technologies Driving the Evolution of Automated Valve Systems

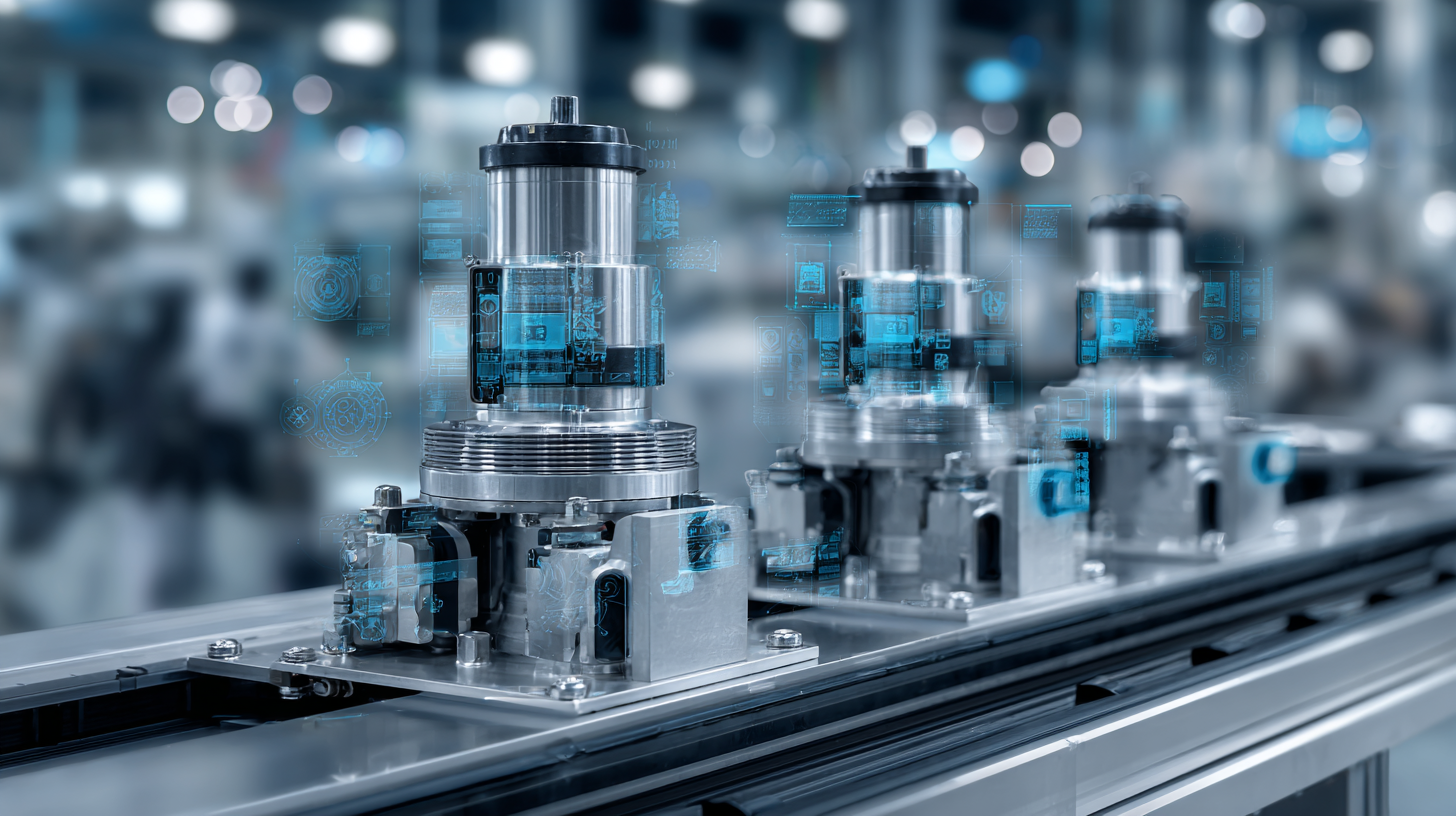

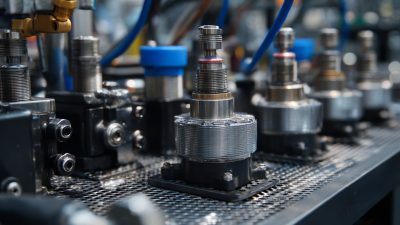

The evolution of automated valve systems is driven by several key technologies that are reshaping flow control in industrial automation. One of the primary technologies is the integration of IoT (Internet of Things) capabilities, which enable real-time monitoring and control of valve operations. This connectivity allows for predictive maintenance, reducing downtime by alerting operators when maintenance is required before a failure occurs. Additionally, the use of sensors within automated valves enhances operational efficiency by providing precise data on flow rates and pressure, facilitating optimal control strategies.

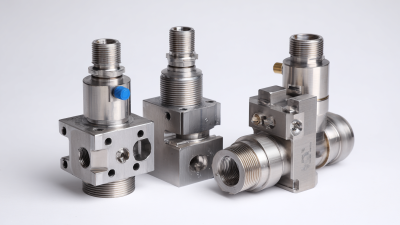

Another significant advancement comes from the development of advanced actuator technologies, including electric, pneumatic, and hydraulic systems. These actuators are designed for rapid response and increased accuracy, enabling industries to fine-tune processes in ways that were previously unattainable. Furthermore, the advent of AI and machine learning technologies empowers automated valve systems to adapt and learn from operational data, ultimately leading to smarter, more efficient flow control solutions. Together, these innovations are propelling industries towards a future where automated valve systems are central to achieving productivity and sustainability goals.

Comparative Analysis: Automated Valves vs. Traditional Flow Control Methods

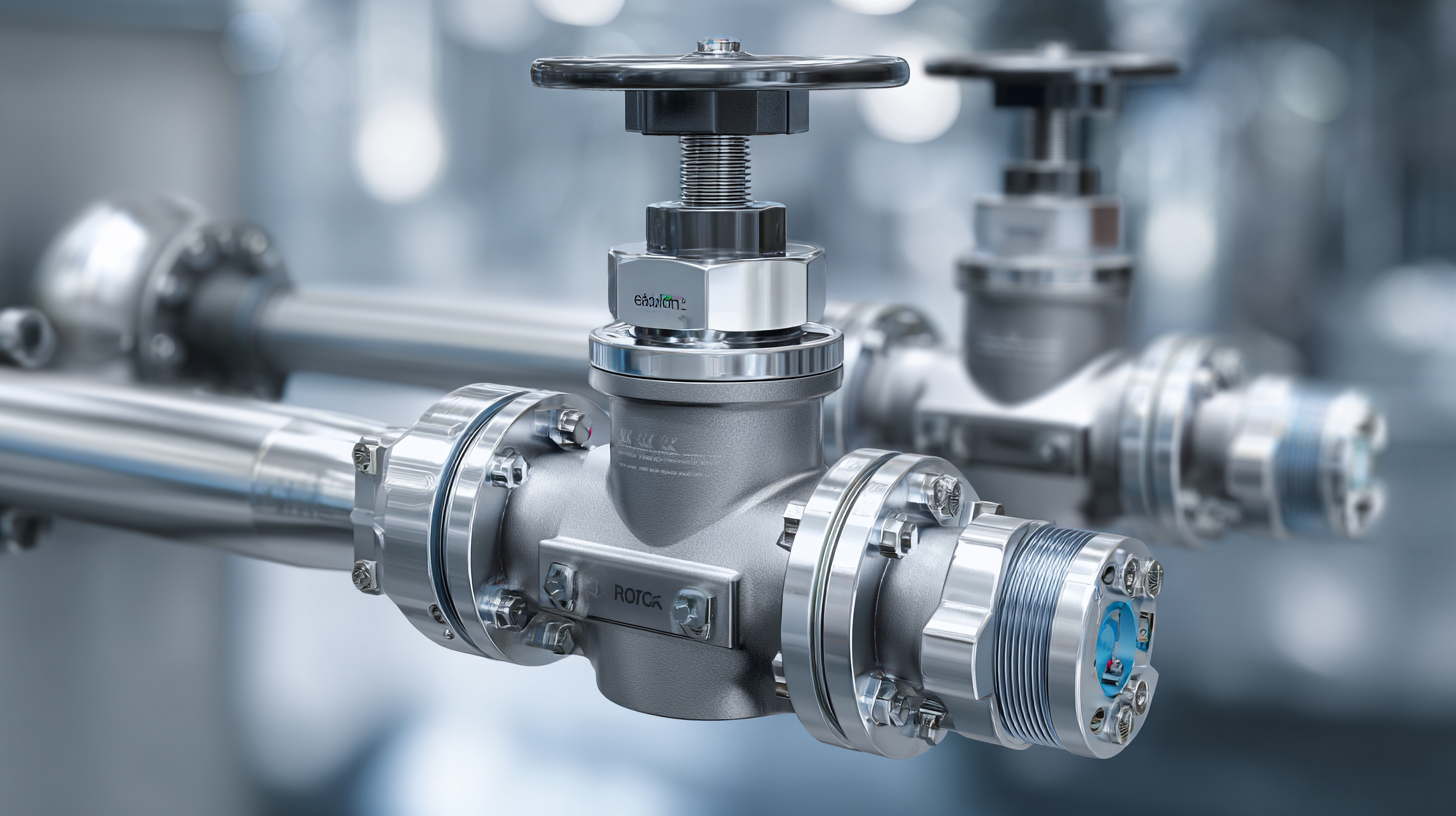

Automated valves are quickly becoming a cornerstone in industrial automation, presenting a significant shift from traditional flow control methods such as manual valves or mechanical actuators. One major advantage of automated valves is their ability to enhance operational efficiency. Unlike traditional methods, which often require manual intervention and are prone to human error, automated valves can be operated through remote control systems and integrated with various sensors. This allows for real-time monitoring and adjustments, optimizing flow rates precisely when needed.

Tips: When considering the transition to automated valves, it’s essential to evaluate your current system’s compatibility. Conduct a thorough analysis to determine which processes can benefit the most from automation and identify potential bottlenecks in existing workflows. This proactive approach ensures a smoother implementation and maximizes the benefits of your investment.

Another notable difference is the maintenance aspect. Traditional flow control methods often require extensive manual checks and maintenance schedules, which can be labor-intensive and risky. Automated valves, equipped with smart technology, can provide diagnostic data and alerts for maintenance needs, thereby reducing downtime and increasing safety. This shift not only lowers operational costs but also enhances overall productivity within the industrial setting.

Tips: Implementing predictive maintenance strategies can further enhance the reliability of automated valves. By analyzing performance data, facilities can anticipate failures before they occur, thereby minimizing unexpected outages and ensuring that operations run seamlessly.

Integration Challenges: Adapting Automation in Existing Industrial Infrastructure

As industries move toward greater automation, integrating automated valves into existing infrastructures presents significant challenges. According to a report from the International Society of Automation, approximately 70% of industrial facilities still rely on legacy systems that lack compatibility with modern automation technologies. This disparity complicates the process of retrofitting and upgrading plants to accommodate new automated solutions, often resulting in increased downtime and substantial costs.

Moreover, as noted by a study from MarketsandMarkets, the global market for automated valves is projected to reach $7.2 billion by 2025, fueled by increasing demand for efficiency and precision in industrial processes. However, organizations must navigate the complexities of legacy integration, including data standardization and system interoperability. Failing to address these integration challenges can hinder the full benefits of automation, such as improved operational efficiency and reduced maintenance costs, which can offer a competitive edge in the rapidly evolving industrial landscape.

Future Trends: How AI and IoT Will Further Transform Flow Control Solutions

The Industrial Internet of Things (IIoT) is rapidly transforming the manufacturing landscape by enhancing operational efficiency and enabling smart manufacturing. A comprehensive review of IIoT reveals its pivotal role in driving the digital transformation of various industries. By integrating sensors, data analytics, and connectivity, IIoT facilitates real-time monitoring and control of manufacturing processes, ultimately leading to optimized resource utilization and reduced downtime.

One of the key frameworks emerging from IIoT advancements is the five-layer architecture, which illustrates the progressive evolution of smart manufacturing. This layered approach includes device level, connectivity, edge computing, data accumulation, and application layers, each contributing to the overall effectiveness of industrial systems. Furthermore, seven critical technologies have been identified as catalysts for accelerating manufacturing transformation. These technologies encompass AI-driven analytics, advanced robotics, cybersecurity, edge computing, cloud infrastructure, predictive maintenance, and digital twins, collectively enhancing the resilience and adaptability of manufacturing operations in a constantly evolving market.

Related Posts

-

What is the Future of Automated Valves in Modern Industries

-

How to Select the Right Hydraulic Pressure Relief Valve for Your System Needs

-

Unlocking Global Opportunities for Check Valves at China Import and Export Fair 2025

-

Understanding the Power of Pneumatic and Hydraulic Systems in Modern Industry with Over 300 Billion USD Revenue

-

Essential Checklist for Selecting the Right Hydraulic Check Valves for Your Applications

-

10 Essential Flow Control Valves Every Industry Should Consider

skip to Main Content

skip to Main Content