Why Choose Automated Valves for Your Industry Needs?

In today's rapidly evolving industrial landscape, the demand for efficiency is at an all-time high. Automated valves play a crucial role in optimizing processes. According to Dr. Sarah Thompson, an expert in industrial automation, “Harnessing the power of automated valves can transform operational efficiency.” This statement emphasizes the significance of integrating these valves into various systems.

Automated valves offer precision and reliability that manual systems often lack. Industries are under pressure to enhance productivity while minimizing costs. Automated valves can streamline operations, reducing the need for constant human oversight. By automating flow control, companies can focus on more complex tasks, allowing for greater innovation.

However, the transition to automated valves is not without challenges. Initial costs can be daunting. Companies must consider training and maintenance as part of the switch. Adapting to new technology requires time and a willingness to change. The path to full automation may present hurdles, but the long-term benefits can outweigh the initial difficulties.

Benefits of Automated Valves in Modern Industrial Applications

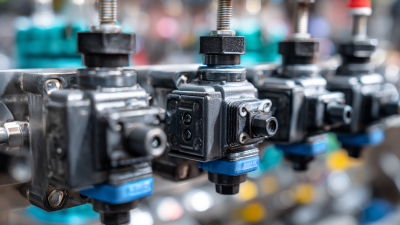

Automated valves are becoming essential in modern industries. They enhance efficiency and precision in various applications. In processes requiring quick adjustments, these valves excel. They can operate with minimal human intervention, allowing for smooth workflows. This automation leads to reduced operational costs and increased safety.

One key advantage is their ability to provide accurate control. Automated valves respond rapidly to system changes. This means processes remain stable even under varying conditions. However, not all systems benefit from automation equally. Some traditional setups may require careful evaluation before implementation. It’s crucial to assess the specific needs before making a decision.

Moreover, automated valves can reduce waste and improve resource management. By optimizing flow rates, industries conserve energy and materials. This contributes to sustainability efforts, which is increasingly important today. Yet, integrating these technologies can pose challenges. Staff may need retraining, and initial investments can be substantial. Balancing these factors is essential for long-term success.

Key Industry Statistics Supporting the Use of Automated Valves

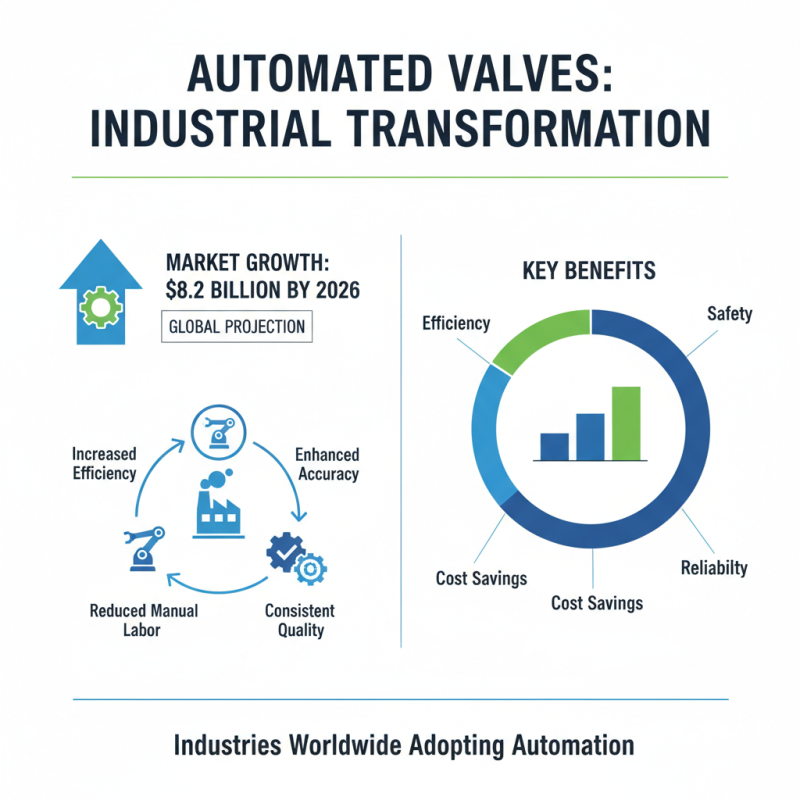

Automated valves are transforming industries worldwide. According to the latest market analysis, the automated valve market is projected to reach $8.2 billion by 2026. This growth reflects a rising demand for efficiency in industrial processes. Industries are recognizing the benefits of automated systems. These systems can reduce manual labor and enhance accuracy in operations, ensuring consistent quality.

Where precision and safety are paramount, automated valves shine. A report indicates that 60% of industries using these valves report fewer operational errors. This statistic highlights the reliability of automation. In sectors like oil and gas, the stakes are high. Every miscalculation can lead to significant losses or safety hazards. Industry experts suggest that automation can significantly mitigate these risks.

**Tips:** When considering automated valves, assess your specific needs first. Not all systems are created equal. Look for compatibility with your existing infrastructure. Continuous training for operators is crucial. Regular maintenance checks will enhance the system's longevity. Additionally, don't forget to solicit feedback from team members familiar with the valves’ daily operations. Their insights can uncover potential areas for improvement.

Comparison of Automated Valves vs. Manual Valves in Efficiency

When evaluating automation in industrial processes, the efficiency of valves plays a crucial role. Automated valves often outperform manual options in speed and precision. According to a recent industry report, automated valves can improve operational efficiency by up to 30%. This leads to faster task completion, reducing downtime significantly.

Manual valves require human intervention for operation, which can introduce delays and errors. A study found that manual systems had an average error rate of 10%. Human fatigue and environmental factors often hinder performance. In contrast, automated systems operate consistently without fatigue, leading to more reliable outcomes.

Energy efficiency is another area where automated valves excel. They can reduce energy consumption by about 20% compared to manual valves. However, transitioning to automation isn't without challenges. Initial costs can be high, and training staff to use automated systems can require significant time and resources. Adjustments may take time, and not all processes will benefit equally from automation. Understanding these variables is essential before making decisions.

Why Choose Automated Valves for Your Industry Needs? - Comparison of Automated Valves vs. Manual Valves in Efficiency

| Feature | Automated Valves | Manual Valves |

|---|---|---|

| Operation Speed | High (milliseconds) | Low (seconds) |

| Labor Cost | Reduced | Increased |

| Maintenance Frequency | Low | High |

| Precision | High | Moderate |

| Safety | Enhanced (remote operation) | Standard |

| Energy Efficiency | High | Variable |

| Integration with Systems | Easy (smart systems) | Limited |

Impact of Automated Valves on Operational Costs and Resources

Automated valves have become increasingly vital across various industries. They enhance efficiency and reduce operational costs substantially. When implemented effectively, these valves minimize the need for manual operation, creating a more streamlined workflow. Their precision ensures that processes run more smoothly. Fewer errors lead to fewer costly delays.

However, transitioning to automated systems requires thoughtful consideration. Initial investments can be significant. Companies must evaluate the return on investment carefully. Many benefits exist, but challenges can arise. Training staff on new technologies is essential. Maintenance procedures for automated valves must also evolve. Failure to adapt can lead to unexpected costs.

Furthermore, automated valves can consume resources differently. While they save time and reduce labor, energy costs may fluctuate. Companies need to analyze these factors holistically. Understanding the entire system is crucial. An automated valve's success will depend on how well it integrates with existing processes.

Technological Advances Driving the Adoption of Automated Valves

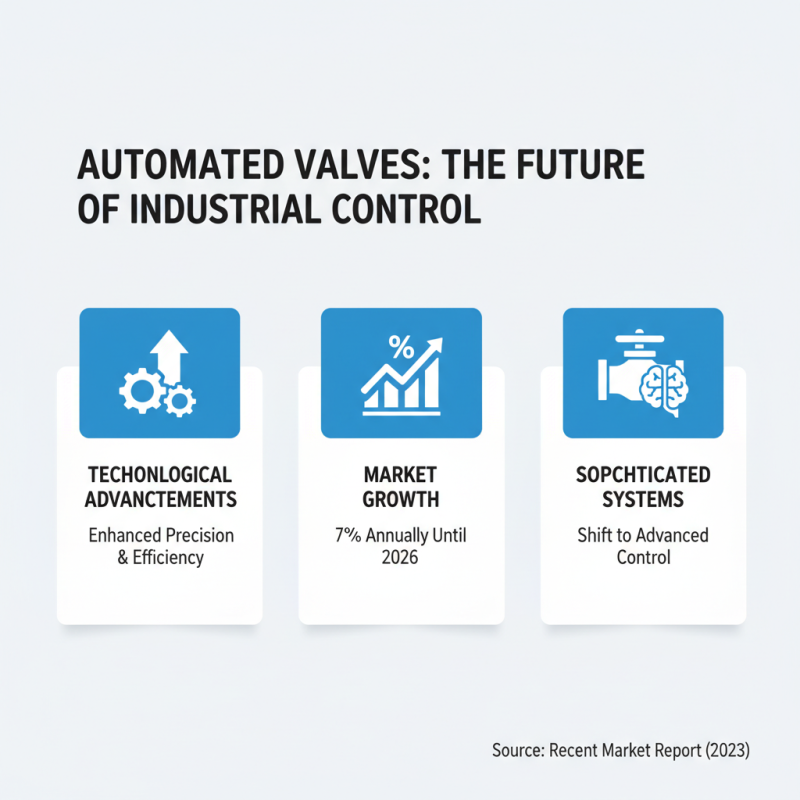

The rise of automated valves is driven by significant technological advances. Industries can now enjoy enhanced precision and efficiency. According to a recent market report, the automated valve market is expected to grow by over 7% annually until 2026. This growth signifies a shift towards more sophisticated control systems.

One of the key advancements in automated valves is the integration of smart technologies. These valves can now communicate with monitoring systems in real time. For instance, sensors equipped in these valves provide critical data about pressure and flow. This allows for quick adjustments and preventative maintenance, potentially saving companies thousands in downtime.

However, challenges remain. The initial investment for automation can be a hurdle for some organizations. Additionally, workforce training is often necessary to operate these advanced systems. Many companies express concern over the reliability of these new technologies. This reflects a need for careful implementation and ongoing evaluation. Only through addressing these issues can industries fully harness the benefits of automated valves.

Related Posts

-

What is the Future of Automated Valves in Modern Industries

-

Revolutionizing Flow Control: How Automated Valves are Shaping the Future of Industrial Automation

-

Exploring the Future of Control Valves: Innovations and Trends Driving Efficiency in Industry

-

2025 How to Choose the Best Control Valves for Your Industrial Applications with Expert Insights

-

Top 2025 Trends in Directional Control Valves You Need to Know

-

Top 2025 Control Valves: Features, Trends, and Buying Guide

skip to Main Content

skip to Main Content