2026 Best Hydraulics Products You Need to Know?

The world of hydraulics products is rapidly evolving. By 2026, market experts predict significant advancements in this field. According to a recent report by Research and Markets, the global hydraulic equipment market is expected to reach $52.5 billion. Such growth indicates an increasing demand for innovative hydraulic solutions across various industries.

Hydraulics products play a crucial role in manufacturing, agriculture, and construction. Specifically, data shows that hydraulic machinery boosts productivity by 30% on average. This efficiency is vital as companies strive to lower costs and improve operational performance. However, not all products meet the industry’s stringent standards. Some options may lack durability or efficiency. This gap can lead to increased downtime and repair costs.

As we approach 2026, understanding the best hydraulics products is essential for any business. Familiarity with both top-tier brands and emerging technologies will foster improvement. Companies need to critically assess available products. Such insight will help them make informed decisions.

2026 Market Overview: Trends and Growth in Hydraulics Products

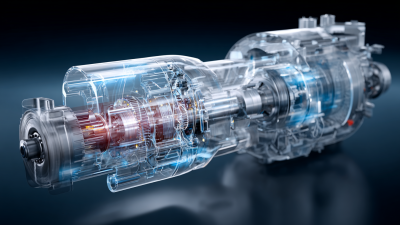

The hydraulics market is evolving. In 2026, we can expect significant trends impacting its growth. One key trend is automation. Companies are investing in automated hydraulic systems for greater efficiency. This shift enhances productivity but poses challenges in maintenance and troubleshooting.

Another notable change is the push for sustainability. Manufacturers are focusing on eco-friendly materials and energy-efficient designs. This trend can reduce environmental impact but often leads to increased costs. It’s a balancing act between sustainability and budget constraints.

Market growth in hydraulics also reflects global economic shifts. Emerging markets show increasing demand for hydraulic solutions. However, companies must be cautious. Not all regions have the same readiness for advanced technologies. Understanding these dynamics is crucial for success in the ever-changing hydraulics landscape.

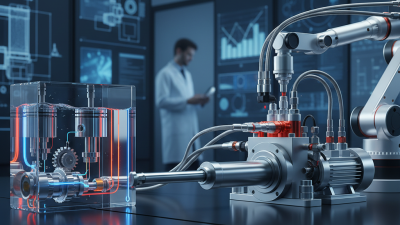

Key Innovations in Hydraulics: Products Revolutionizing the Industry

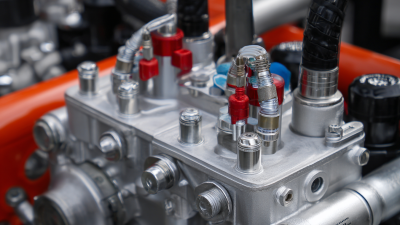

The field of hydraulics is evolving quickly. Innovations in equipment and technology are transforming the industry. Essential products are making systems more efficient and reliable. Advanced hydraulic fluid is now more environmentally friendly. Smart sensors help monitor performance in real-time. These items improve safety and reduce downtime.

Tips: Always check for compatibility before purchasing new hydraulic components. A mismatched part can lead to significant issues down the line. Additionally, keep up-to-date with the latest research. The more you know, the better choices you can make.

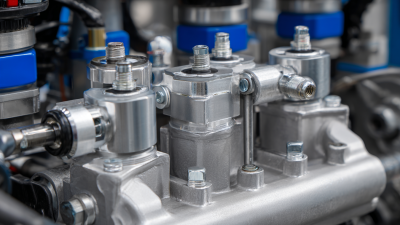

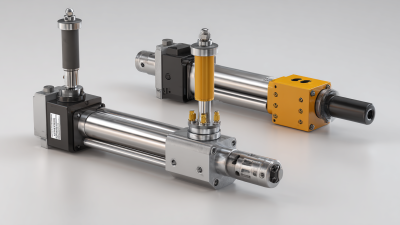

Another area of innovation is in hydraulic pumps. They are now more compact but offer greater power. Compact designs allow for easier integration into existing machinery. However, be mindful of space limitations. The shift towards digital solutions also raises challenges. Systems may require updates or user training. Consider your team’s familiarity with new technology before implementation.

2026 Best Hydraulics Products: Key Innovations in Hydraulics

This chart illustrates the growth in key innovations in the hydraulics industry from 2022 to 2026, showcasing the impact of various product advancements. The categories include Smart Hydraulics, Energy Efficient Pumps, and Advanced Fluid Connectors.

Top Hydraulics Brands for 2026: Who's Leading the Market?

As we approach 2026, the hydraulics market is evolving rapidly. Leading brands are innovating with advanced technologies that enhance performance. These improvements focus on energy efficiency and reliability. Hydraulic systems are critical in construction, manufacturing, and agriculture. Efficiency often means lower operating costs.

Market leaders are adopting smart technologies. Embedded sensors monitor performance in real-time. This feature allows for proactive maintenance. Predictive analytics aids in minimizing downtime. Nonetheless, some companies still struggle to adapt to these changes. They often rely on outdated systems, risking competitiveness.

Consumer demand is shifting towards sustainability. Brands are under pressure to produce environmentally friendly products. This trend may lead to inconsistency in quality. Some may prioritize eco-friendliness over performance. It raises questions about balance and trade-offs in product design. The challenge remains: how to innovate while ensuring quality and reliability?

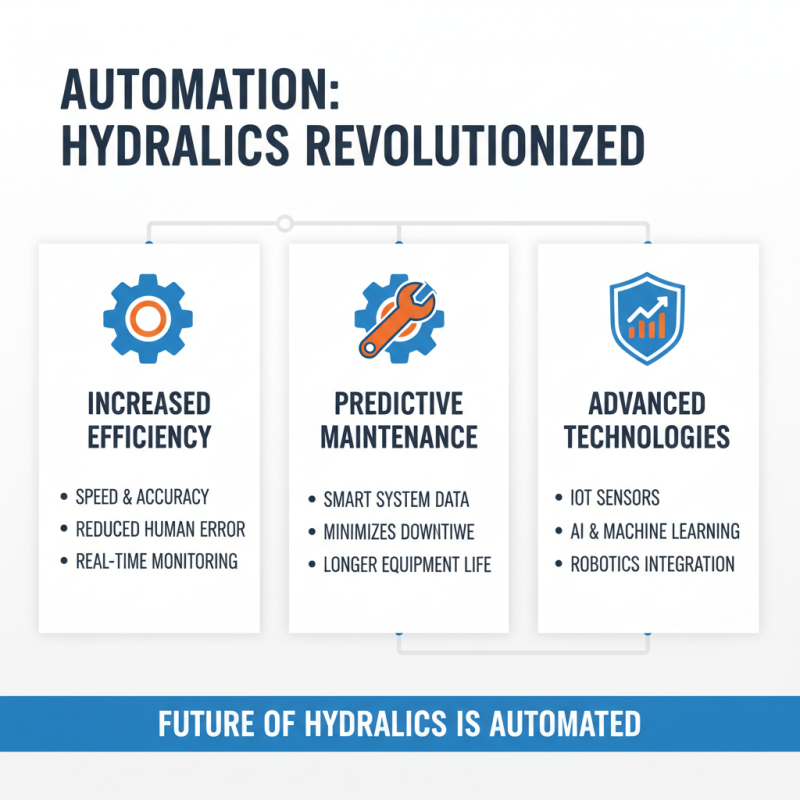

Impact of Automation on Hydraulics Products: Efficiency Gains and Data

Automation is revolutionizing the hydraulics industry. With advanced technologies, efficiency gains are now more accessible. Automation enhances speed and accuracy, reducing human error. Smart systems can monitor performance in real-time. This allows for predictive maintenance and minimizes downtime.

Numerous applications benefit from these advancements. For example, hydraulic presses can operate with precision thanks to automated controls. However, reliance on technology raises concerns. What if systems fail? Additionally, workforce adaptation is essential. Workers need training to handle these sophisticated tools effectively.

Data plays a crucial role in this evolution. It drives decision-making and optimizes processes. Yet, with vast amounts of information, security becomes a pressing issue. Protecting sensitive data is critical. As automation progresses, a balance is needed between technology and human insight. Finding that balance may not be easy.

Safety Standards and Regulations for Hydraulics Products in 2026

In 2026, the emphasis on safety standards for hydraulics products becomes increasingly critical. Compliance with new regulations is essential for manufacturers. These standards aim to minimize operational risks and protect workers. Properly designed hydraulics can lead to greater efficiency and safety on job sites.

Tips: Regularly review your equipment for wear and tear. This ensures longevity and reliability. Use pressure gauges to monitor system performance.

Manufacturers must adapt to evolving regulations. Innovations in material and design can enhance safety features. However, not all companies are keeping up. Some still rely on outdated technologies, putting themselves at risk. Training staff on the latest safety protocols is vital.

Tips: Conduct safety drills regularly. This prepares your team for emergencies. Engage workers in discussions about potential hazards.

The landscape of hydraulics is changing. Companies must prioritize compliance while maintaining product quality. Lack of adherence can lead to penalties and accidents. Being proactive in updating products is non-negotiable. Safety and functionality must go hand in hand.

2026 Best Hydraulics Products You Need to Know

| Product Name | Product Type | Certification Standards | Safety Rating | Year of Compliance |

|---|---|---|---|---|

| Hydraulic Pump A | Pumps | ISO 4413 | A+ | 2026 |

| Hydraulic Cylinder B | Cylinders | ISO 6020 | A | 2026 |

| Hydraulic Hose C | Hoses | SAE J517 | A+ | 2026 |

| Hydraulic Valve D | Valves | ISO 4414 | A | 2026 |

| Hydraulic Fluid E | Fluids | ISO 15380 | A+ | 2026 |

Related Posts

-

What Are the Key Components of Hydraulics Products and Their Applications

-

Why Fluid Power Hydraulics Are Essential for Modern Industry

-

Exploring the Future: Top Fluid Power Hydraulics Trends for 2025+

-

2025 How to Understand Fluid Power Hydraulics for Beginners and Experts

-

5 Best Fluid Power Hydraulics Solutions for Optimal Performance

-

Essential Guide to Understanding Hydraulics Products for Everyday Applications

skip to Main Content

skip to Main Content