2025 Top+ Directional Control Valves: Market Insights and Trends Driving Industry Growth

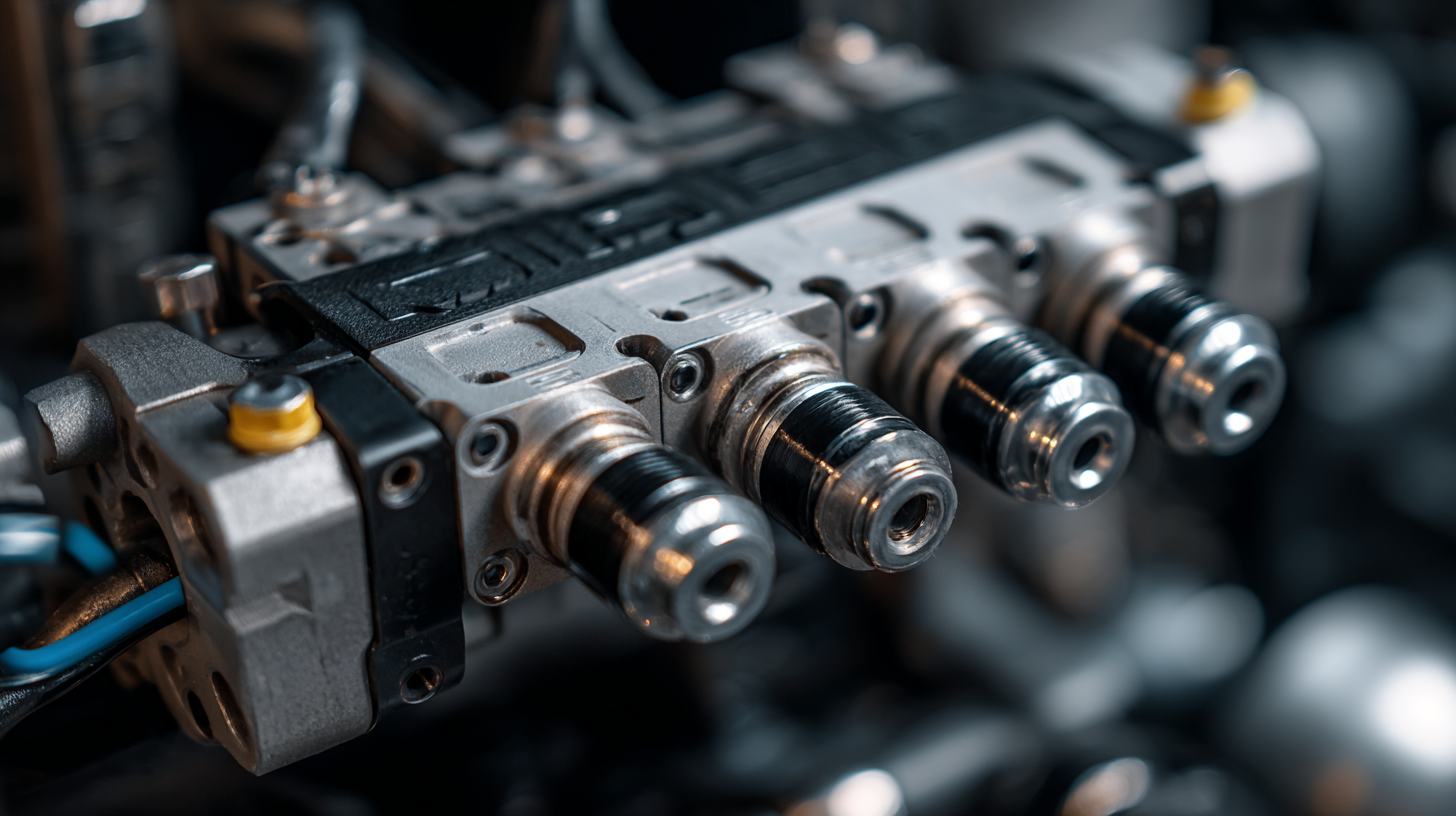

As the global market for directional control valves continues to expand, it is essential to understand the forces shaping this growth and the trends that are driving innovation within the industry. According to a recent report by MarketsandMarkets, the directional control valves market is projected to reach USD 9.2 billion by 2025, growing at a CAGR of 5.2% during the forecast period. This robust growth can be attributed to the increasing demand for automated industrial processes and advancements in technology that enhance operational efficiency across various sectors, including manufacturing, automotive, and robotics.

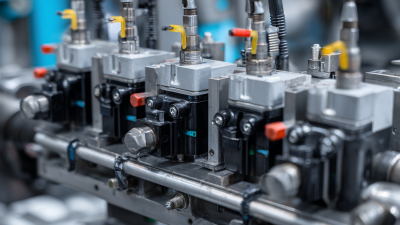

Industry expert Dr. Emily Harper, a leading analyst at Valves Insights, emphasizes the critical role of directional control valves in boosting productivity. She states, "Directional control valves are the backbone of fluid power systems, enabling precise control and reliability in operations." As industries strive for greater automation, the evolution of these valves will be pivotal in meeting the challenges posed by modernization and sustainability goals. Continuous innovation in design and functionality, alongside the integration of smart technology, will play a significant role in shaping the future landscape of directional control valves, positioning them as indispensable components in the machinery of tomorrow.

Emerging Technologies in Directional Control Valves for 2025

The directional control valve market is set to experience transformative growth by 2025, fueled largely by emerging technologies. Innovations such as IoT integration, advanced materials, and energy-efficient designs are redefining performance standards. According to a recent industry report by MarketsandMarkets, the global directional control valves market is projected to reach $10.3 billion by 2025, growing at a CAGR of 5.8%. This surge is primarily driven by the demand for automation in manufacturing processes and the increasing need for efficient fluid control systems.

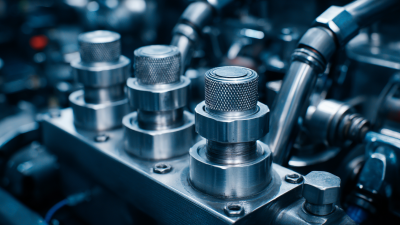

One of the most significant trends is the adoption of smart valves, which utilize sensor technologies for real-time monitoring and control. This advancement not only enhances operational efficiency but also minimizes downtime and maintenance costs. For instance, companies implementing IoT-enabled directional control valves can reduce energy consumption by up to 30%, as highlighted in a study by Research and Markets.

Tip: As you consider upgrading your fluid control systems, assess the compatibility of new technologies with your existing infrastructure. Investing in modular designs can provide flexibility and scalability, allowing for easier integration of future innovations. Staying informed about the latest developments in directional control valves will position businesses ahead of the competition in an evolving market landscape.

Market Segmentation Trends in the Directional Control Valve Industry

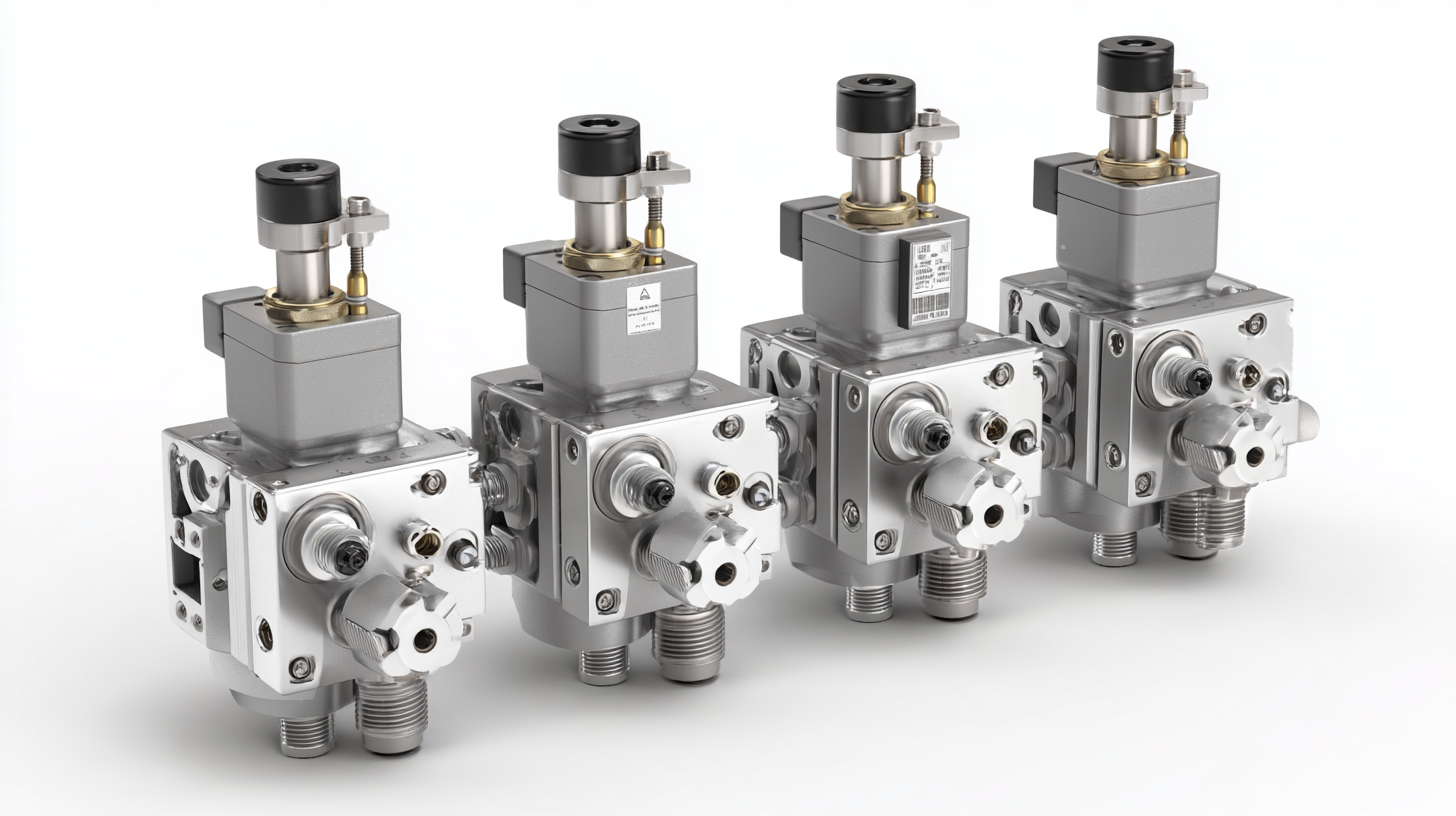

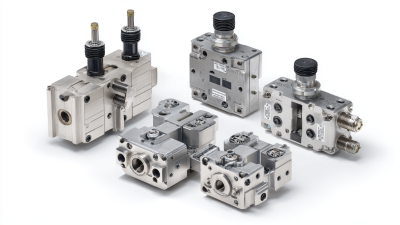

The directional control valve industry is experiencing significant growth, driven by advancements in technology and increasing demand across various sectors. Market segmentation plays a crucial role in understanding consumer needs, as manufacturers tailor their products to meet specific applications. Key segments include electromagnetic, hydraulic, and mechanical valves, each designed for different operational efficiencies and environment compatibility. This diversification not only enhances performance but also opens new avenues for innovation and market expansion.

When navigating the complexities of the directional control valve market, it's essential for businesses to focus on customer-centric strategies. **Tip:** Conduct thorough market research to identify the unique requirements of each segment, allowing for targeted product development. Additionally, staying updated with industry trends and technological breakthroughs can provide a competitive edge.

As sustainability becomes a priority, manufacturers are also adapting their offerings to incorporate eco-friendly materials and energy-efficient designs. **Tip:** Engage with customers to understand their sustainability goals; this will not only enhance your product appeal but also align your brand with their values. Leveraging these insights can lead to more effective marketing strategies and foster long-term partnerships within the sector.

2025 Top+ Directional Control Valves: Market Insights and Trends Driving Industry Growth

| Market Segment | Market Share (%) | Growth Rate (CAGR %) | Key Application Areas |

|---|---|---|---|

| Hydraulic Directional Control Valves | 40% | 6.5% | Construction Machinery, Agricultural Equipment |

| Pneumatic Directional Control Valves | 30% | 5.2% | Packaging Machines, Textile Industry |

| Solenoid Directional Control Valves | 20% | 4.8% | Automation, Robotics |

| Other Types | 10% | 3.5% | Specialty Applications |

Key Drivers Fueling Growth in the Directional Control Valve Market

The directional control valve market is experiencing robust growth, driven by several key factors. According to a recent report by MarketsandMarkets, the market is projected to reach $7.73 billion by 2025, with a CAGR of 5.4% from 2020 to 2025. This growth is primarily fueled by the increasing demand for automation in various industrial sectors, including manufacturing, automotive, and oil & gas. As companies strive to enhance efficiency and reduce operational costs, the integration of advanced valve technologies has become essential for optimizing systems and processes.

Another significant driver is the rising focus on sustainable and energy-efficient solutions. As industries shift toward greener practices, the need for high-performance directional control valves that minimize energy consumption and waste is becoming paramount. A study published by ResearchAndMarkets indicates that the adoption of smart and digital technologies in the valve sector will play a pivotal role in shaping the future landscape, with IoT-enabled solutions gaining traction to offer enhanced control and monitoring capabilities. This trend not only promotes operational efficiency but also aligns with global sustainability goals, further propelling market growth.

Competitive Landscape: Leading Players in Directional Control Valves

The competitive landscape of the directional control valves market is characterized by the presence of several key players who are enhancing their market position through innovation and strategic partnerships. Leading companies are investing significantly in research and development to introduce advanced valve technologies that improve efficiency and reliability. This innovation-driven approach not only boosts product offerings but also caters to the evolving demands of various sectors such as automotive, aerospace, and industrial machinery.

Additionally, collaborations and mergers among industry leaders are shaping the competitive dynamics of the market. These alliances facilitate the sharing of resources and expertise, enabling companies to expand their product portfolios and strengthen their market reach. Furthermore, the growing emphasis on automation and digitalization in manufacturing processes is prompting players to integrate smart technologies into their directional control valves, providing a competitive edge and meeting customer expectations for enhanced functionality and performance. As these trends continue to evolve, the strategic initiatives undertaken by leading players will play a pivotal role in driving industry growth and shaping the future of the directional control valves market.

2025 Top Directional Control Valves Market Insights

Sustainability and Innovation in Directional Control Valve Manufacturing

The directional control valve manufacturing sector is experiencing a transformative shift towards

sustainability and innovation. As environmental concerns escalate, manufacturers are increasingly focused on designing valves that not

only meet performance standards but also minimize ecological footprints. This includes the use of recyclable materials and the incorporation of energy-efficient production processes.

By adopting green manufacturing practices, companies are not only reducing waste but also appealing to environmentally-conscious consumers and industries that prioritize sustainability

in their procurement processes.

Related Posts

-

Exploring Innovative Alternatives in Control Valves: A Global Purchasing Perspective

-

How to Optimize Hydraulic Flow Control Valves for Maximum Efficiency

-

Ultimate Guide to Understanding Check Valves and Their Applications

-

10 Essential Flow Control Valves Every Industry Should Consider

-

Why Fluid Power Hydraulics Are Essential for Modern Industry

-

Exploring the Efficiency of Hydraulic Solenoid Valves: Industry Trends and Performance Data

skip to Main Content

skip to Main Content